Split type brake disc

A brake disc, split technology, applied in the direction of the brake disc, brake type, brake components, etc., can solve the problem of the vehicle not running normally and the high cost of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

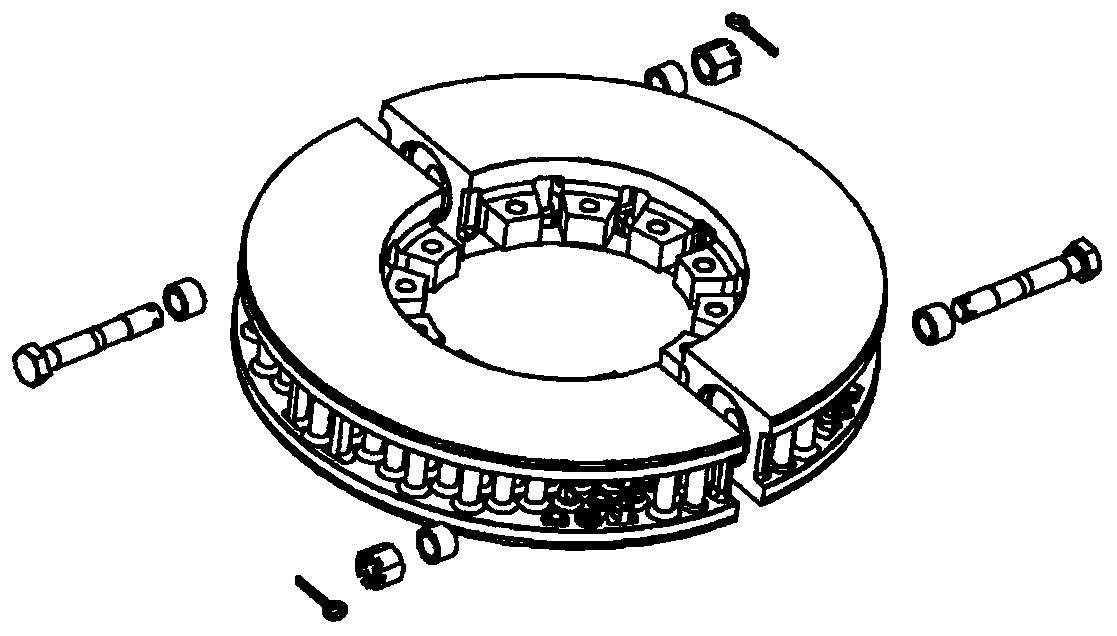

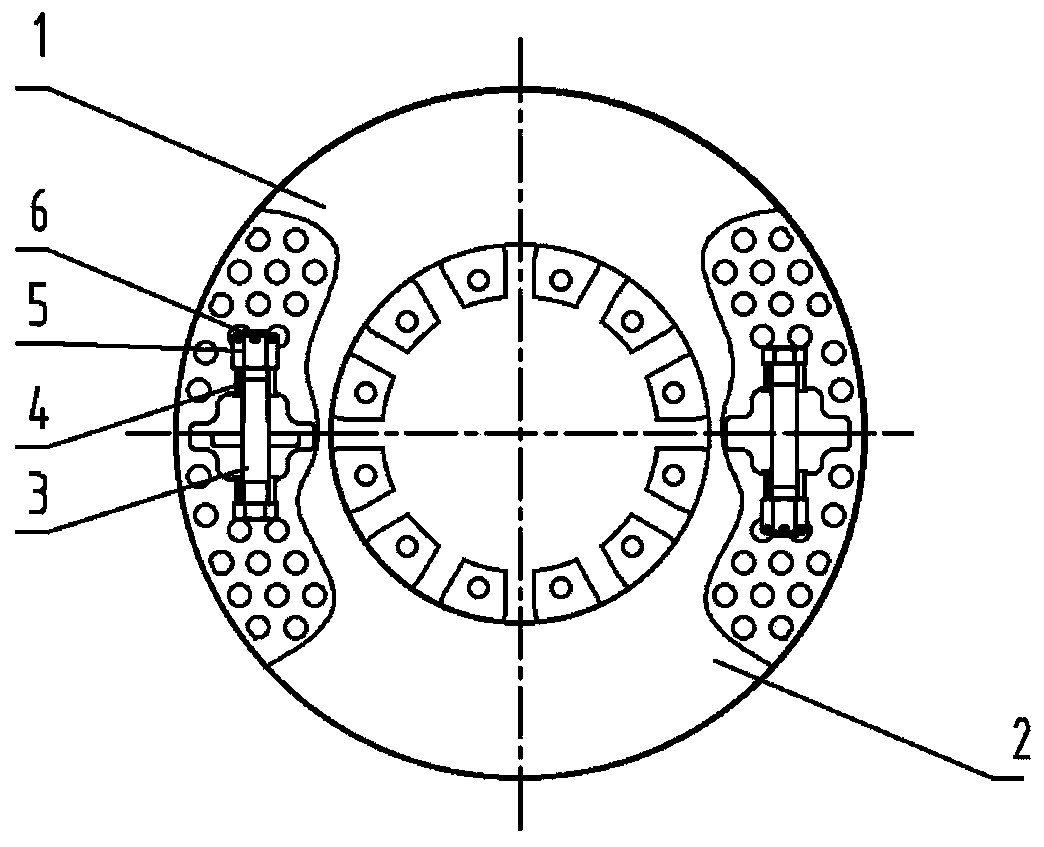

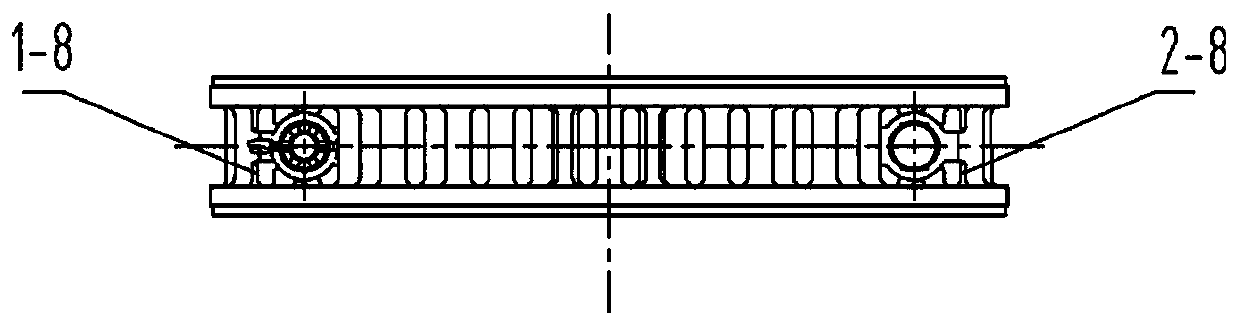

[0080] Such as Figure 1-7 As shown, the split brake disc of the present invention has two sub-disc bodies, namely the first sub-disc body 1 and the second sub-disc body 2, the first connecting piece is a bolt 3, which also includes a spacer 4 , nut 5, cotter pin 6. Wherein the first sub-disc body 1 and the second sub-disc body 2 are both half disc bodies, and the nut 5 is a slotted locking nut.

[0081] Wherein, the first sub-disc body 1 is composed of two semicircular first sub-disc body friction rings 1-1, the first sub-disc body first cooling ribs 1-2 connecting the two friction rings 1-1, and the The inner side of the ring is composed of the second cooling ribs 1-8 of the first sub-disc body and a number of first sub-disc body connecting claws 1-3 located on the inner ring of the friction ring 1-1 and evenly distributed in the circumferential direction;

[0082] The second sub-disc body 2 is composed of two semicircular second sub-disc body friction rings 2-1, the second...

Embodiment 2

[0112] Such as Figure 8-12 As shown, the first positioning surface 1-6-1 is parallel to the first force transmission surface 1-6-2, and the second positioning surface 2-6-1 is parallel to the second force transmission surface 2- 6-2 parallel. Specifically, grooves 2-6 are of the reverse groove type. The first connecting piece is a bolt 3, and the bolt 3 passes through the groove 2-6, and the groove 2-6 runs through the connecting surface of the second sub-disc body in the axial direction of the brake disc, and the groove The width of the bottom of the groove 2-6 in the radial direction of the brake disc is greater than the width of the top of the groove 2-6 in the radial direction of the brake disc, the convex key 1-6 is adapted to the groove 2-6, and the rest Technical feature is identical with embodiment 1.

Embodiment 3

[0114] Such as Figure 13-17 As shown, the normal vector of the first positioning surface 1-6-1 pointing to the interior of the convex key 1-6 and the normal vector of the first force transmission surface 1-6-2 pointing to the interior of the convex key 1-6 The angle between the vectors is greater than 90 degrees, the normal vector of the second positioning surface 2-6-1 pointing to the inside of the groove and the normal vector of the second force transmission surface 2-6-2 pointing to the inside of the groove The angle between the vectors is greater than 90 degrees. Specifically, grooves 2-6 are dovetail grooves. The first connecting piece is a bolt 3, and the bolt 3 passes through the groove 2-6, and the groove 2-6 runs through the connecting surface of the second sub-disc body in the axial direction of the brake disc, and its The width of the bottom in the radial direction of the brake disc is larger than the width of the top in the radial direction of the brake disc, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com