Production technology for plastic soft water band

A production process and soft water belt technology, applied in the direction of coating, etc., can solve the problems of high cost, easy glue peeling, and low production efficiency, and achieve the effect of high cost, easy peeling, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

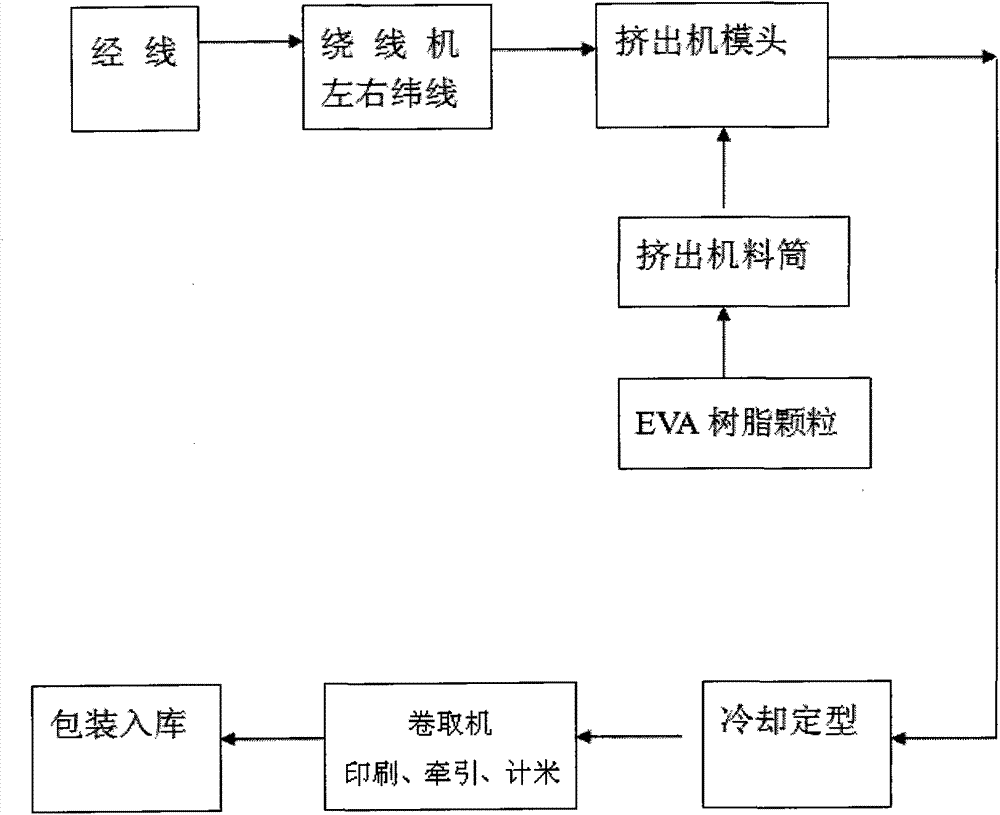

[0018] attached figure 1 It is a specific embodiment of the present invention. This invention a kind of production technology of plastic water softener, comprises the following steps:

[0019] 1. Fix the warps required for the manufacture of EVA soft water belts on the brackets of the two pay-off racks respectively. Place 80 100D twisted polyester threads on each pay-off rack, and install 160 wire spindles in total. The warp threads are tightened by each wire spindle. After adjusting the tightness, the wire device passes through the bracket inlaid with porcelain eyes in turn, and then passes through the front and rear discs of the guide rod of the winding machine and the weft thread under the traction of the winder, and enters the die head of the plastic extruder together.

[0020] 2. The front and rear discs of the winding machine are respectively equipped with 24 wire storage cylinders, and 80D polyester thread ingots are placed in the cylinders, and each thread is adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com