Disposable degradable dish and preparation method therefor

A disposable, body-based technology, applied in the field of disposable degradable discs and its preparation, can solve the problems of easy mildew in the degradation process, insufficient degradation of starch-based discs, etc., to avoid entanglement, improve stability, and enhance adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

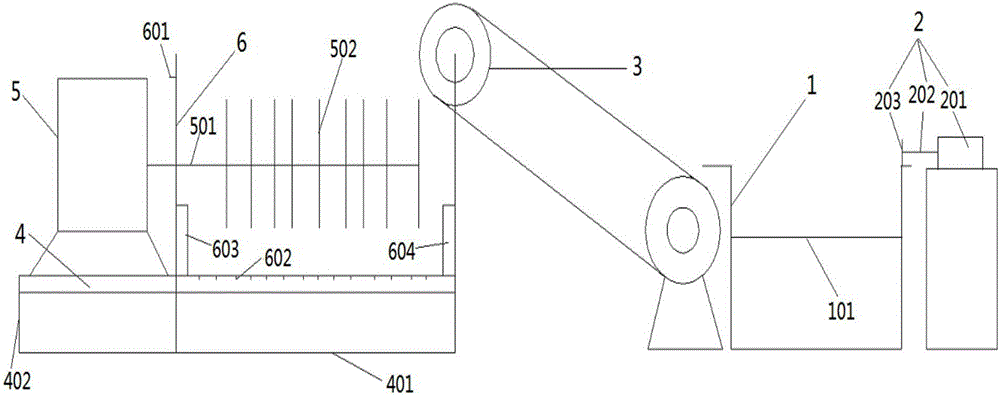

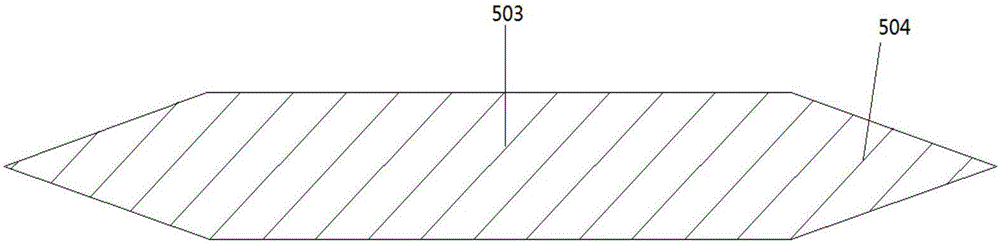

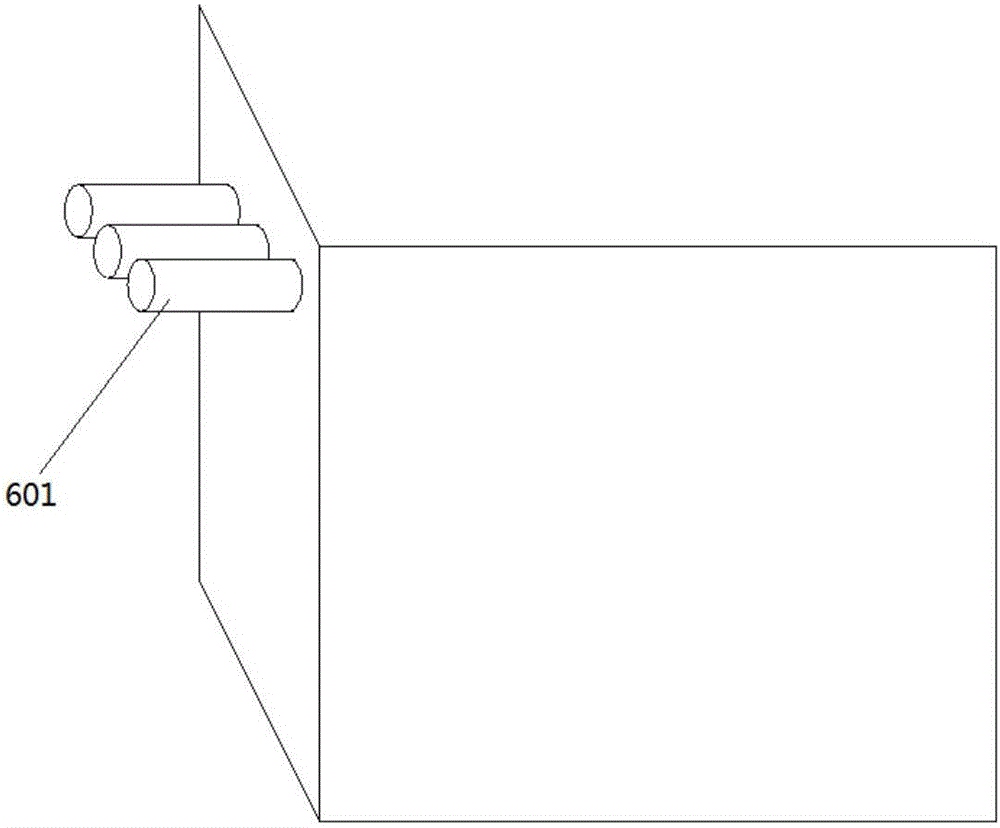

Method used

Image

Examples

Embodiment 1

[0038] A disposable degradable disc, comprising a degradable disc body and an inner membrane coated on the inner surface of the degradable disc body:

[0039] The degradable disc body includes the following raw materials in parts by weight: 50 parts of tapioca starch, 20 parts of abaca fiber, 10 parts of kapok fiber, 15 parts of polylactic acid fiber, 10 parts of saponin rice, 6 parts of malt dextrose, 4 parts of glycerin 10 parts of polyvinyl alcohol, 6 parts of pectin, 2 parts of capillary, 2 parts of Artemisia annua, 2 parts of pekoe, 2 parts of Alisma, 1 part of Andrographis paniculata, 1 part of Radix Radix, 1 part of Radix Paeoniae Alba and 1 part of Danshen;

[0040] The inner film comprises the following raw materials in parts by weight: 20 parts of acetyl tributyl citrate, 4 parts of oxidized starch, 3 parts of edible gelatin and 6 parts of fruit and vegetable cellulose powder.

[0041] Wherein, the fruit and vegetable cellulose powder is made of the following raw mat...

Embodiment 2

[0054] A disposable degradable disc, comprising a degradable disc body and an inner membrane coated on the inner surface of the degradable disc body:

[0055] The degradable disc body includes the following raw materials in parts by weight: 70 parts of tapioca starch, 25 parts of abaca fiber, 20 parts of kapok fiber, 25 parts of polylactic acid fiber, 15 parts of saponin rice, 10 parts of malt dextrose, 6 parts of glycerin 20 parts of polyvinyl alcohol, 8 parts of pectin, 4 parts of capillary root, 4 parts of Artemisia annua, 4 parts of pekoe, 4 parts of Alisma, 3 parts of Andrographis paniculata, 3 parts of Radix Radix, 3 parts of Radix Paeoniae Alba and 3 parts of Salvia miltiorrhiza;

[0056] The inner film comprises the following raw materials in parts by weight: 25 parts of acetyl tributyl citrate, 6 parts of oxidized starch, 5 parts of edible gelatin and 8 parts of fruit and vegetable cellulose powder.

[0057] Wherein, the fruit and vegetable cellulose powder is made of...

Embodiment 3

[0070] A disposable degradable disc, comprising a degradable disc body and an inner membrane coated on the inner surface of the degradable disc body:

[0071] The degradable disc body includes the following raw materials in parts by weight: 60 parts of tapioca starch, 22 parts of abaca fiber, 15 parts of kapok fiber, 20 parts of polylactic acid fiber, 12 parts of saponin rice, 8 parts of malt dextrose, 5 parts of glycerin 15 parts of polyvinyl alcohol, 7 parts of pectin, 3 parts of capillary, 3 parts of Artemisia annua, 3 parts of pekoe, 3 parts of Alisma, 2 parts of Andrographis paniculata, 2 parts of Radix Radix, 2 parts of white peony root and 2 parts of Danshen;

[0072] The inner film comprises the following raw materials in parts by weight: 22 parts of acetyl tributyl citrate, 5 parts of oxidized starch, 4 parts of edible gelatin and 7 parts of fruit and vegetable cellulose powder.

[0073] Wherein, the fruit and vegetable cellulose powder is made of the following raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com