Method for designing secondary air extraction device

A technology of an air pumping device and a design method, which is applied to mechanical equipment, pumps with flexible working elements, liquid variable capacity machines, etc., can solve the problems of not applying air pumping devices, not considering non-rigid deformation of diaphragm pistons, etc. To achieve a reasonable effect of the design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

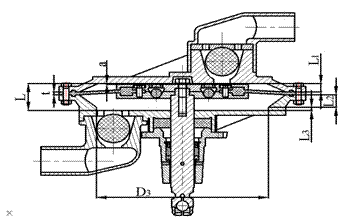

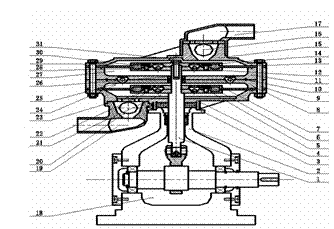

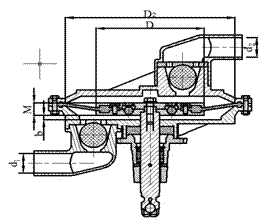

[0108] A secondary air extraction device embodiment of the present invention is such as figure 1 structure shown, figure 1 , figure 2 and image 3 The structure and working principle of an embodiment of a secondary air extraction device designed by the design method provided by the present invention will be described together.

[0109] According to the actual space conditions, the diaphragm pump can be arranged horizontally, vertically and obliquely during operation. combine figure 1 , to describe the embodiment of the secondary air extraction device when it is vertically arranged, and the embodiments in other arrangement states are the same.

[0110] The end of the secondary air extraction device close to the driving mechanism 18 is the first stage low-pressure intake end. The part surrounded by the first-stage upper wall 8 and the first-stage lower wall 4 is the first-stage cavity, and the part surrounded by the last-stage upper wall 15 and the last-stage lower wall 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com