Design method of double electric low-pressure reversing valve for electro-hydraulic control valve group of deep-sea oil tree

An electro-hydraulic control valve, deep-sea Christmas tree technology, applied in computing, electrical digital data processing, instruments, etc., can solve the problem of insufficient operation stability of double-electric low-voltage reversing valve, inability to design structural verification and verification, insufficient calculation accuracy, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

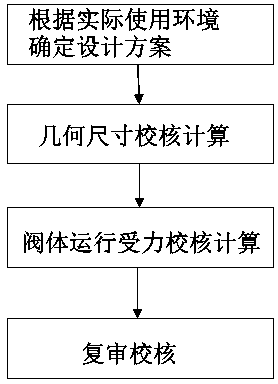

[0121] like figure 1 A design method for a double-electric low-pressure reversing valve of an electro-hydraulic control valve group of a deep-sea oil tree is shown. The design method of a double-electric low-pressure reversing valve of an electro-hydraulic control valve group of a deep-sea oil tree includes the following steps:

[0122] The first step is to determine the design scheme according to the actual use environment. According to the actual environment of the deep sea underwater operation of the valve body and the condition of the working medium, initially determine the applicable range of the effective working environment of the valve body, set various operating technical indicators of the valve body and The basic mechanical structure of the valve body:

[0123] working environment:

[0124] The above-mentioned hydraulic valves are all installed in a sealed container at a water depth of 3000 meters in the ocean

[0125] 1.2 Temperature requirements:

[0126] 1) Sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com