Detection method of optical element refractivity and detection device thereof

A technology of optical components and detection methods, applied in the direction of testing optical properties, phase influence characteristics measurement, etc., can solve the problems of not representing the refractive index of optical components, inability to prepare samples, devitrification, etc., and achieve convenient use, simple structure, and interference accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

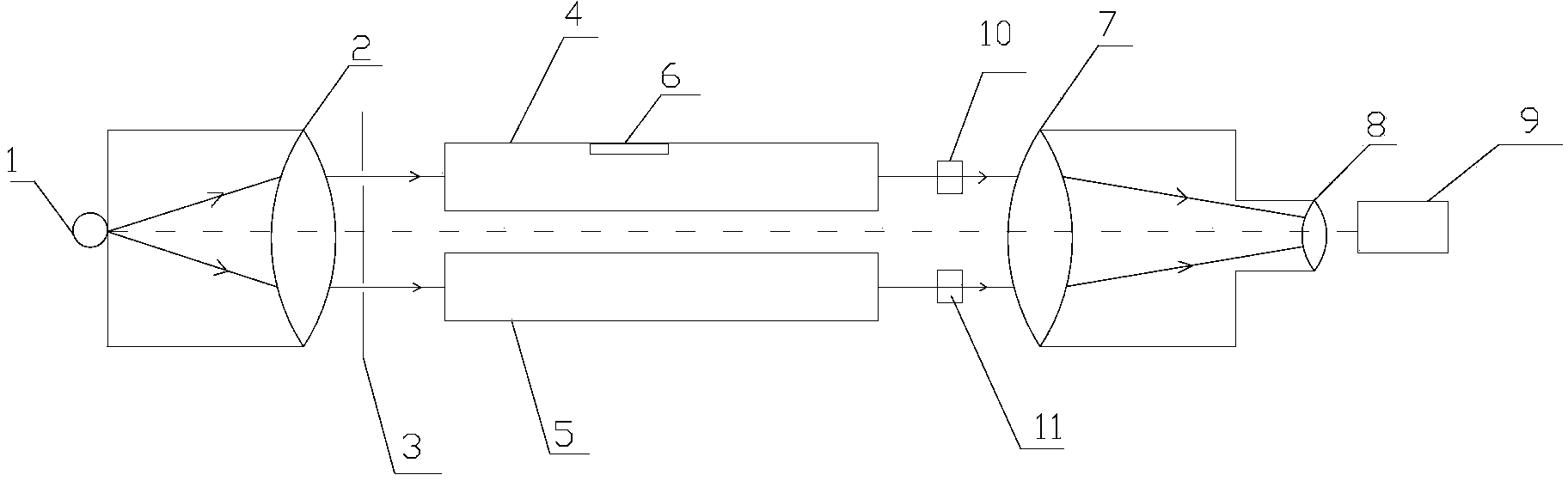

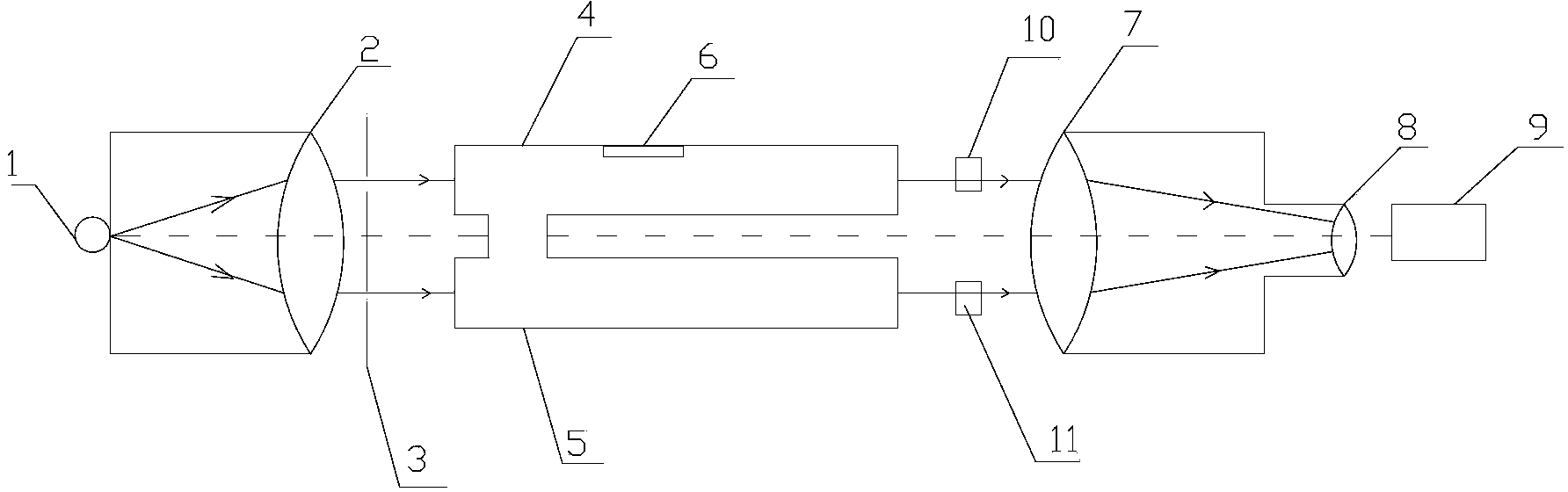

[0022] The present invention utilizes a Rayleigh interferometer (Rayleigh interferometer), and adopts its characteristics of high double-beam interference precision, simple structure, and convenient use to realize non-destructive high-precision testing of the refractive index of small or special-shaped optical elements.

[0023] The detection device of the present invention is followed by the light path in order: light source 1, collimating lens 2, optical slit 3, sample pool, compensator, converging lens 7, cylindrical mirror 8 and observation tube 9, and above-mentioned sample pool comprises the first sample pool 4 and the second sample cell 5, the compensator includes a first compensator 10 and a second compensator 11, and a small hole 6 is opened on the first sample cell 4.

[0024] figure 1 Shown is the optical path diagram of the present invention for detecting the refractive index of small optical elements such as squares and circles with regular shapes and sizes.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com