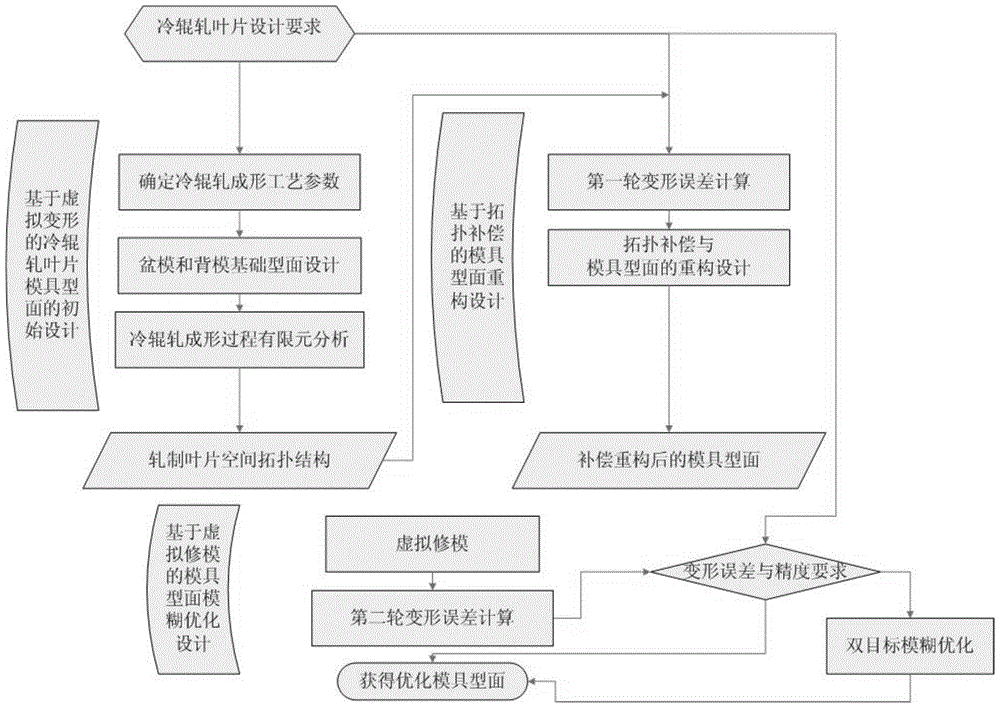

Topology Compensation Fuzzy Optimal Design Method of Die for Cold Rolling of Blades without Allowance

A design method and topology compensation technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of multiple trial repairs, long design cycle, high scrap rate, etc., to reduce scrap rate, shorten design cycle, reduce The effect of the number of trial repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Example: Design of Cold Rolling Die for GH4169 Alloy Engine Compressor Rotor Blade

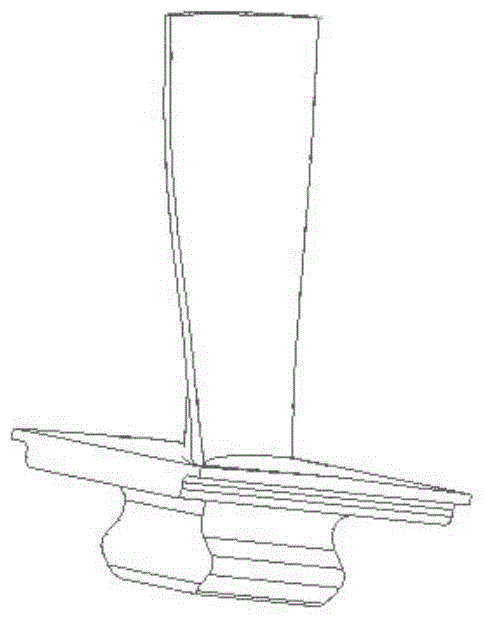

[0052] This embodiment is to design and optimize the precise geometric profile of the rolling die without allowance, refer to the attached Figure 2-13 The present invention will be further described. Taking the cold rolling die surface of the GH4169 alloy engine compressor rotor blade as the design target, the appearance of the blade is as follows figure 2 shown.

[0053] The design optimization process of this type of blade without margin roll die includes the following steps:

[0054] 1. Determine the process parameters of cold roll forming, including rolling die width 50-55mm, roll speed 0.3rad / s, groove center angle 60° and friction factor 0.15.

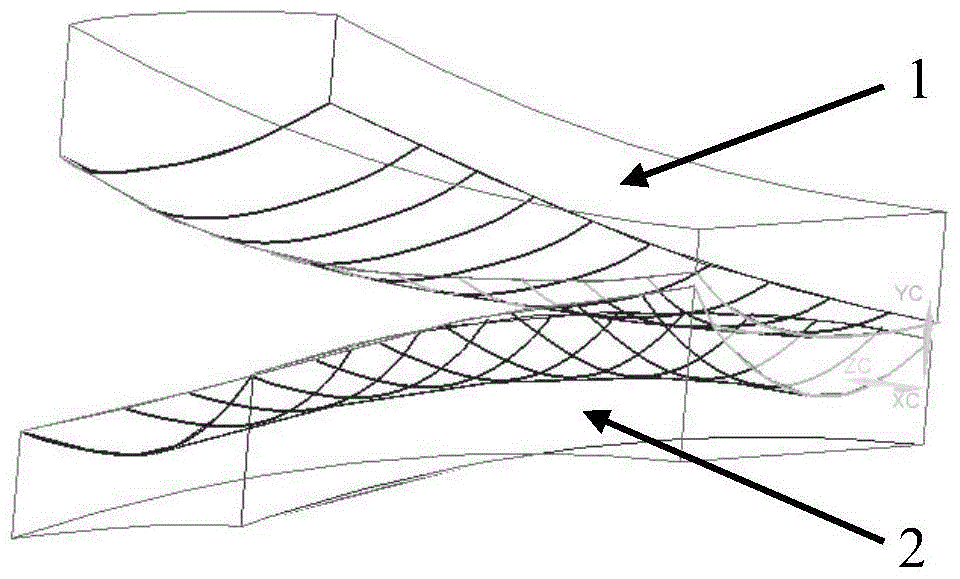

[0055] 2. According to the "Design Method of Roller Die for Rolling Blades Without Allowance", the basic profiles of basin mold 1 and back mold 2 are designed as follows image 3 shown. Among them, "Design Method of Rolling Die for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com