Cover tap stripping device of carrier band and stripping method

A technology of peeling device and cover tape, applied in the direction of electrical components, electrical components, etc., can solve the problems of the stop of the carrier tape and the inability to enter the carrier tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

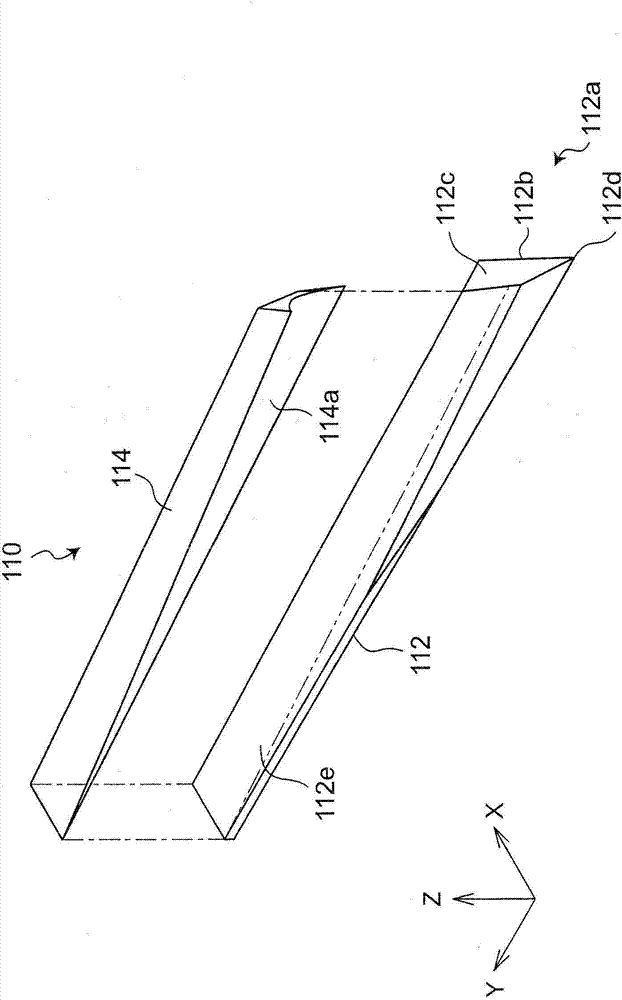

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0037] First, before describing the cover tape peeling device of the carrier tape of the present embodiment, the component supply device which is the premise of the present invention will be described.

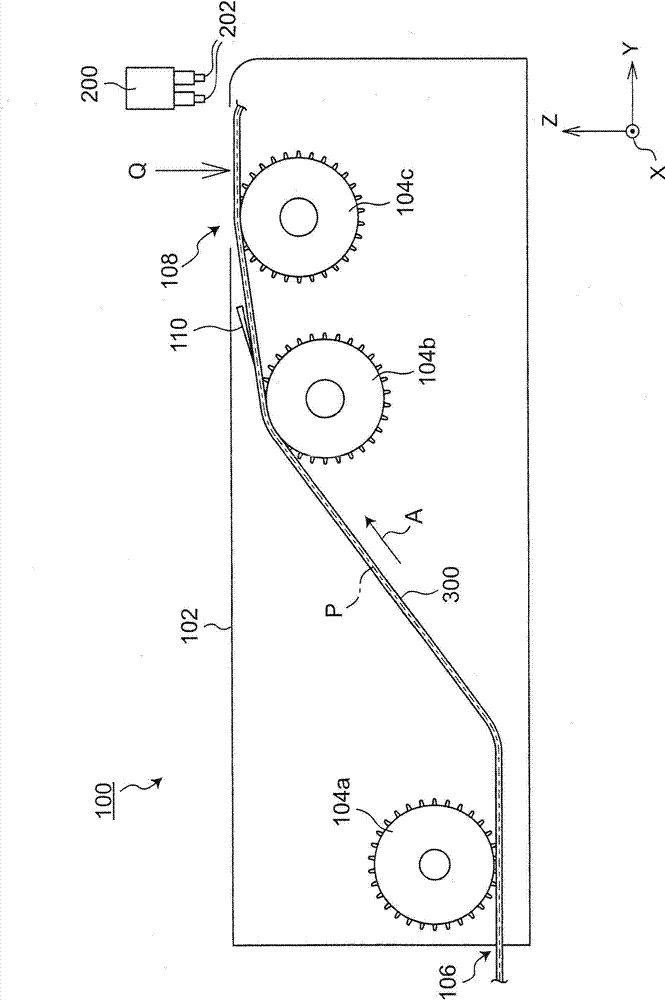

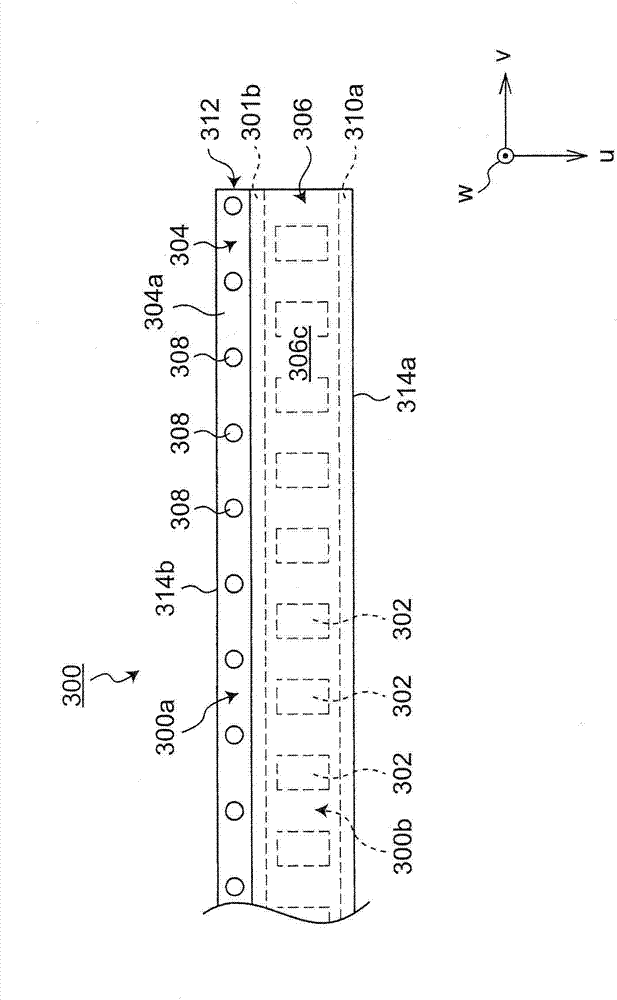

[0038] figure 1 The structure of an example of the components supply apparatus is shown schematically. The component supply device 100 is configured to supply components to the nozzle 202 of the transfer head 200 of the component mounting device. Specifically, the component supply device 100 will figure 2 The illustrated carrier tape 300 accommodating a plurality of components is along the tape conveyance direction A ( figure 2 The tape length direction shown) is sequentially conveyed, and the components accommodated in the carrier tape 300 are supplied to the nozzles 202 of the transfer head 200 at the component supply position.

[0039] figure 2 The front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com