Leaching assembly

A component and leaching technology, which is applied in the preparation of wine, the preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of high hazard, the integration of coloring components and polyphenol substances, affecting the quality of wine, etc., and achieve reliable operation. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

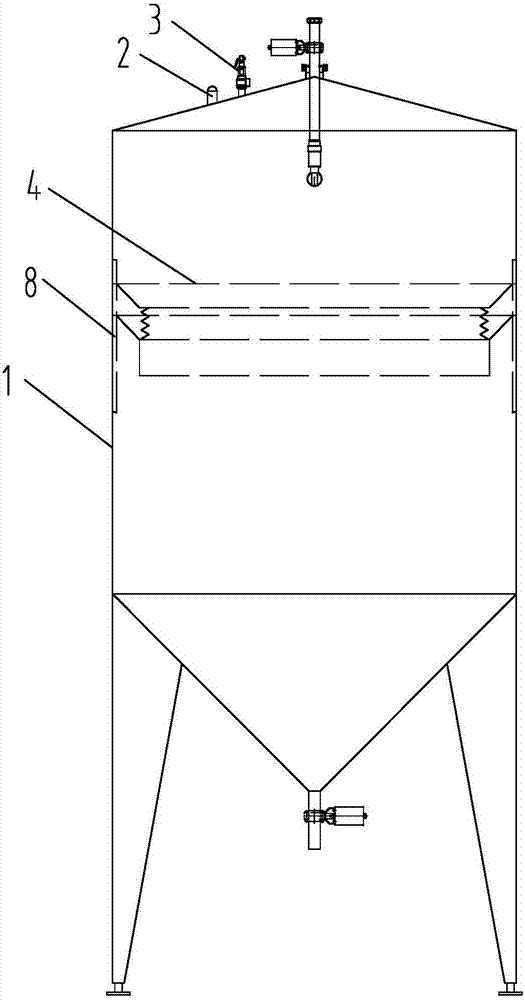

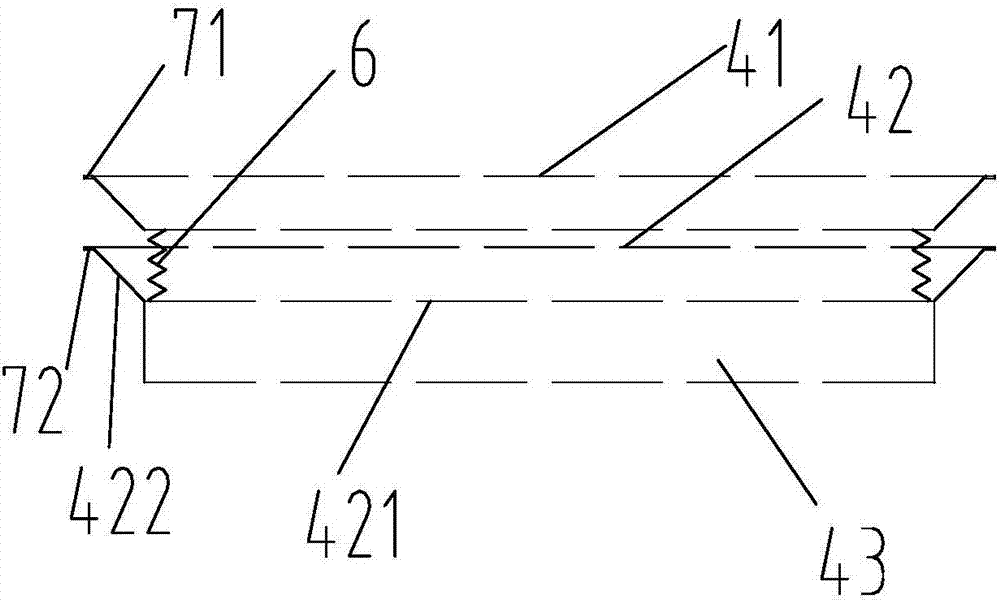

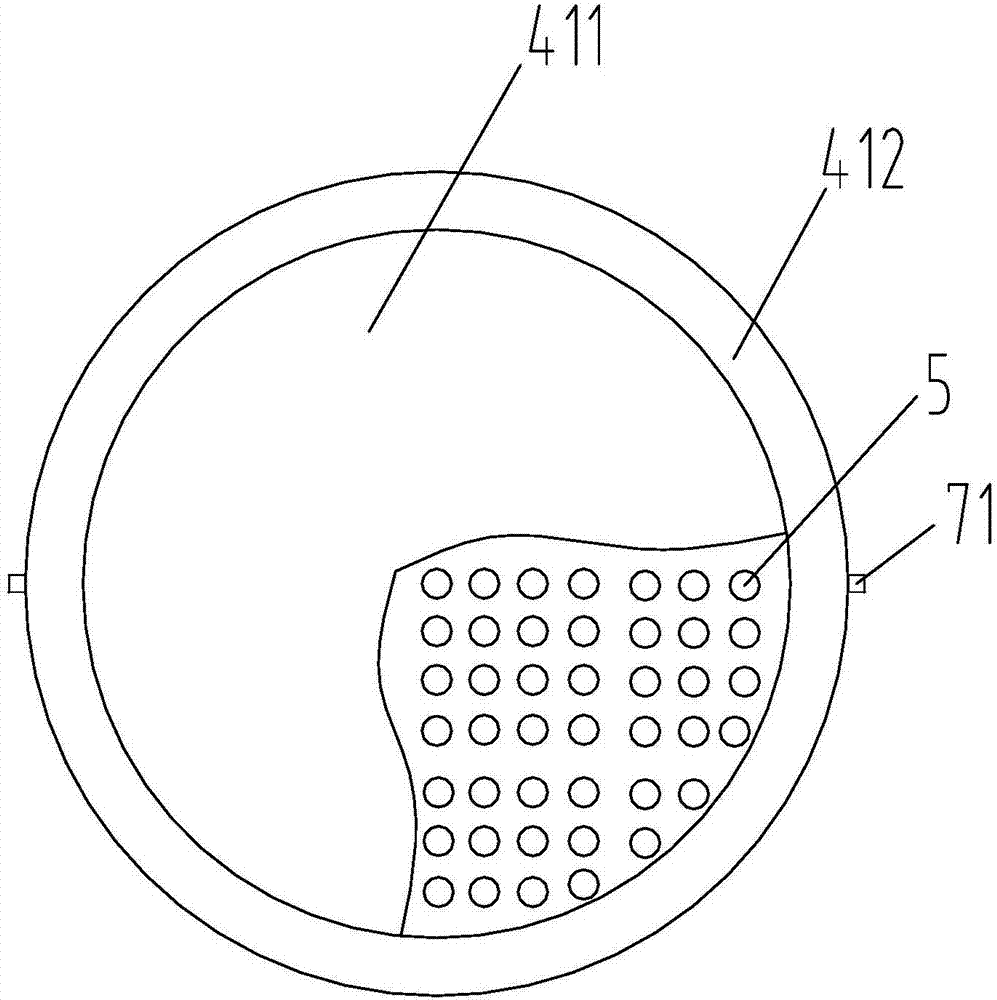

[0027] The present invention as Figure 1-4 As shown, taking the processing of wine as an example: it includes a tank body 1, a gas pressure detection gauge 2 and an exhaust valve 3, and also includes a leaching assembly 4, which includes a filter hopper 41, a filter hopper 2 42 and a filter hopper arranged in sequence. Filter bucket three 43, the filter bucket one 41 has a connected circular filter disc one 411 and annular skirt one 412, the filter disc one 411 is located in the skirt one 412, and the skirt one is set outward ,

[0028] The filter bucket 2 42 has a connected circular filter disc 421 and an annular skirt 2 422, the filter disc 2 is located in the skirt 2, and the skirt 2 is set outwards so that the grape skins and grape seeds gather in the middle;

[0029] The third filter bucket 43 is an open filter cartridge, a spring 6 is arranged between the first filter disc 411 and the second filter disc 421, and the filter cartridge is connected to the second filter d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com