Wine fermentation tank

A fermenter and wine technology, which is applied in the field of food processing, can solve the problems of astringent taste and lower quality of wine, and achieve the effect of reliable turning action, improving quality and avoiding the formation of wine cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

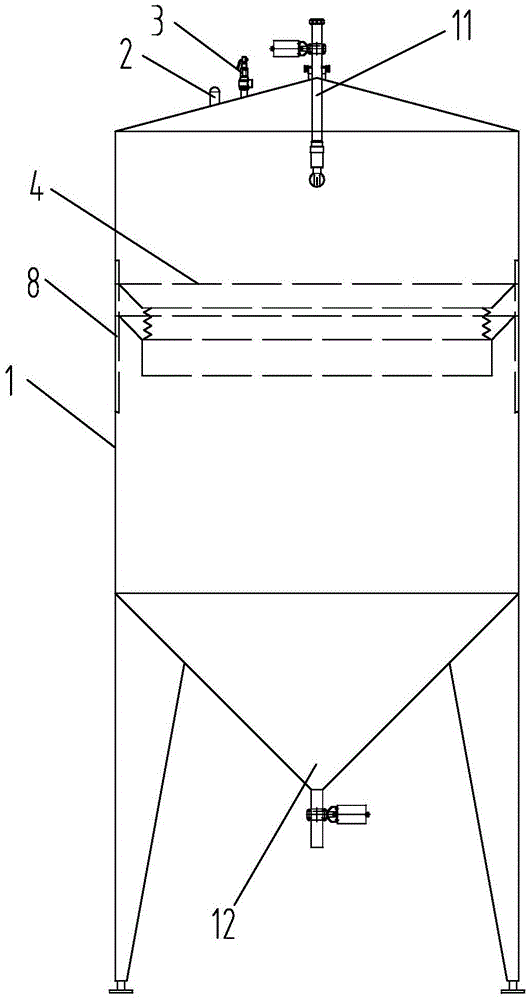

[0051] The present invention as Figure 1-12 As shown, it includes a tank body 1, the top of the tank body is an upper inlet 11, and the bottom is a lower outlet 12. The tank body is provided with a gas pressure detection gauge 2 and an exhaust valve 3, which is convenient for control through the detection of gas pressure Exhaust valve action, easy to operate;

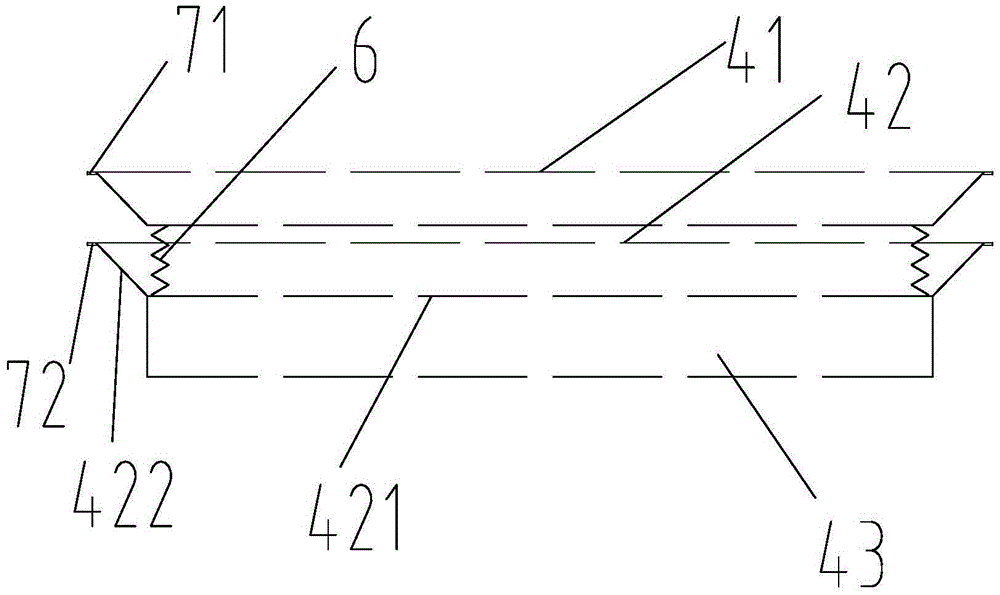

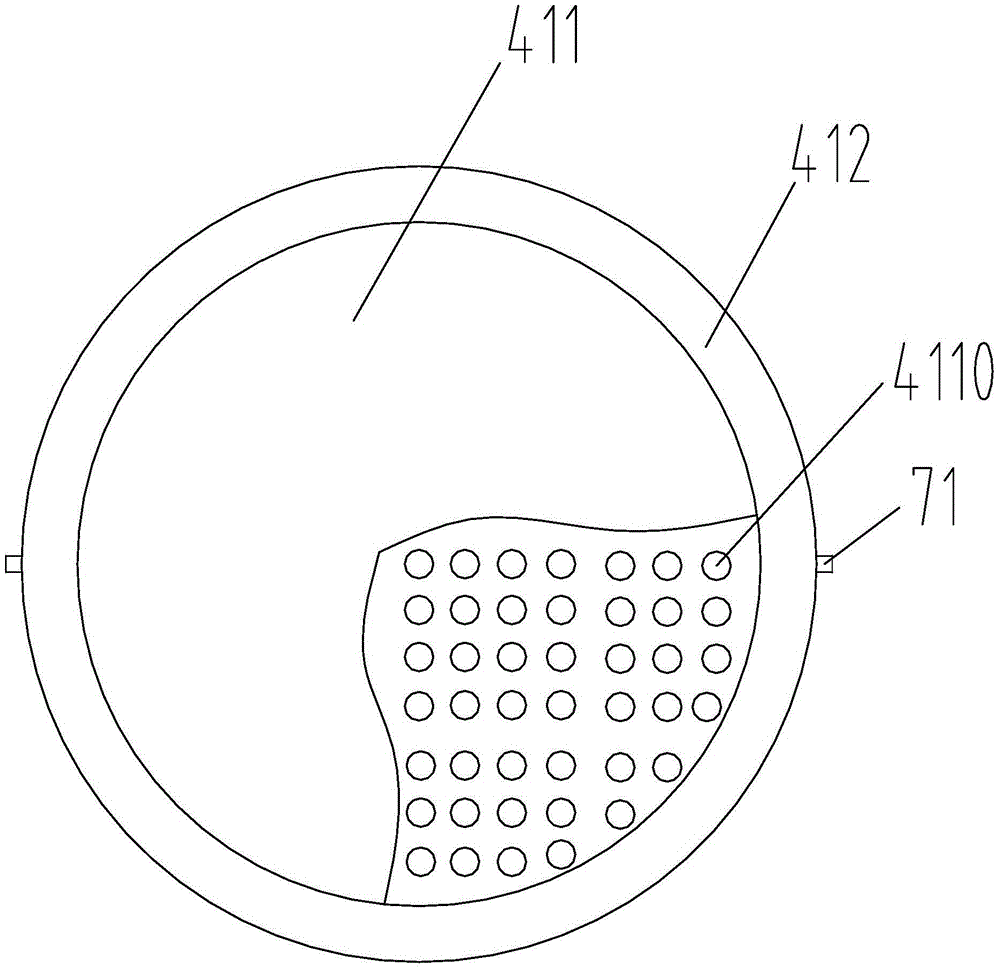

[0052] It also includes a leaching assembly 4 and a driving assembly 5, the leaching assembly is turned over by the driving assembly, the leaching assembly 4 includes a filter bucket 1 41, a filter bucket 2 42 and a filter bucket 3 43 arranged in sequence, the filter bucket 1 41 has a connected circular filter disc 1 411 and annular skirt 1 412, the filter disc 1 411 is located in the skirt 1 412, and the skirt 1 is set outward,

[0053] The filter bucket 2 42 has a connected circular filter disc 421 and an annular skirt 2 422, the filter disc 2 is located in the skirt 2, and the skirt 2 is set outwards so that the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com