Extrusion press and control method for extrusion press

A control method and extruder technology, applied in metal extrusion control equipment, metal containers to be extruded, metal extrusion, etc., can solve problems such as high production costs, large-scale equipment, and complicated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] for the manner in which the invention is carried out

[0029] Next, the extruder apparatus and the control method of the extruder according to the present invention will be described in detail with reference to the drawings.

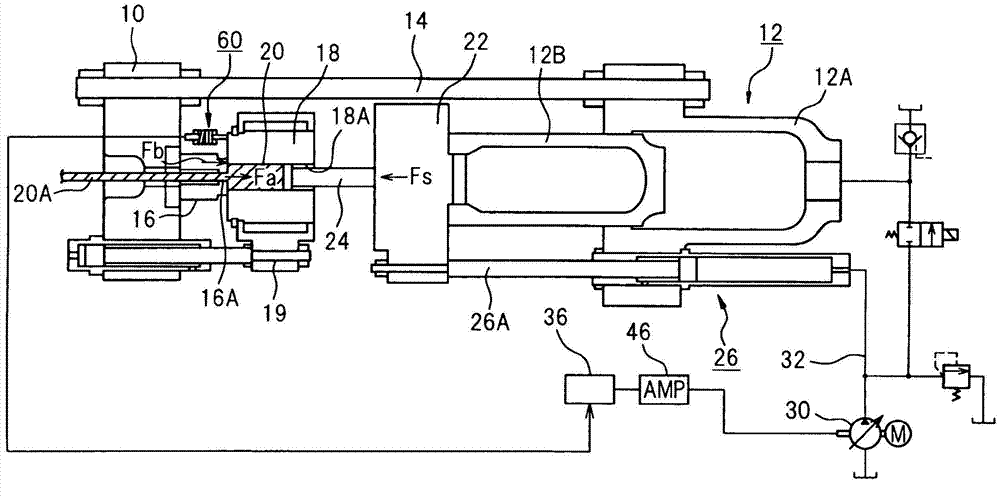

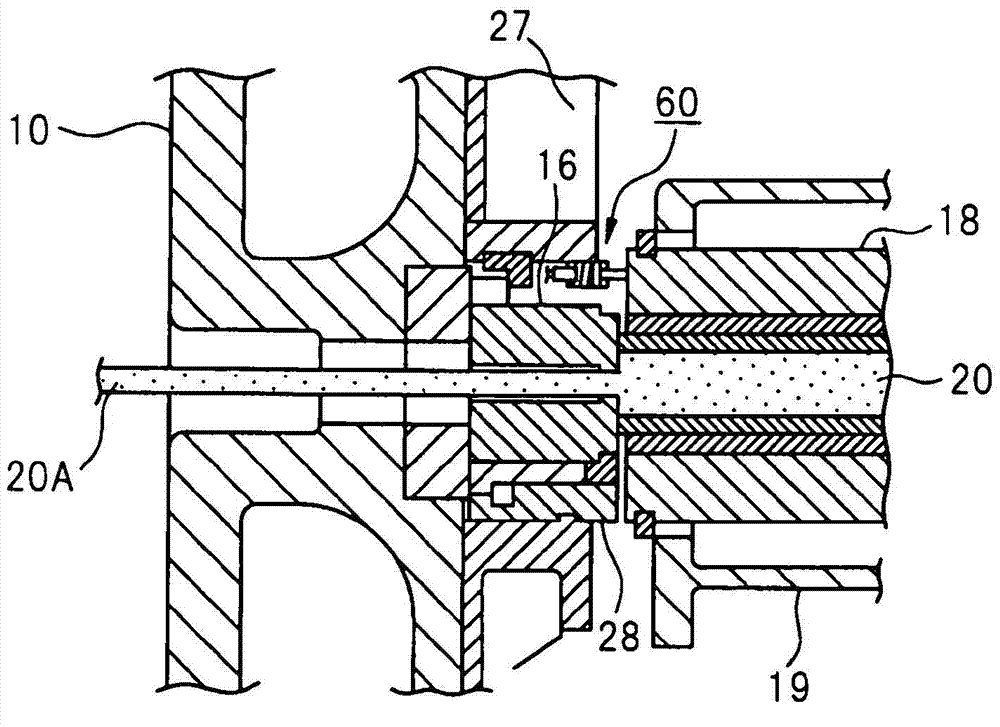

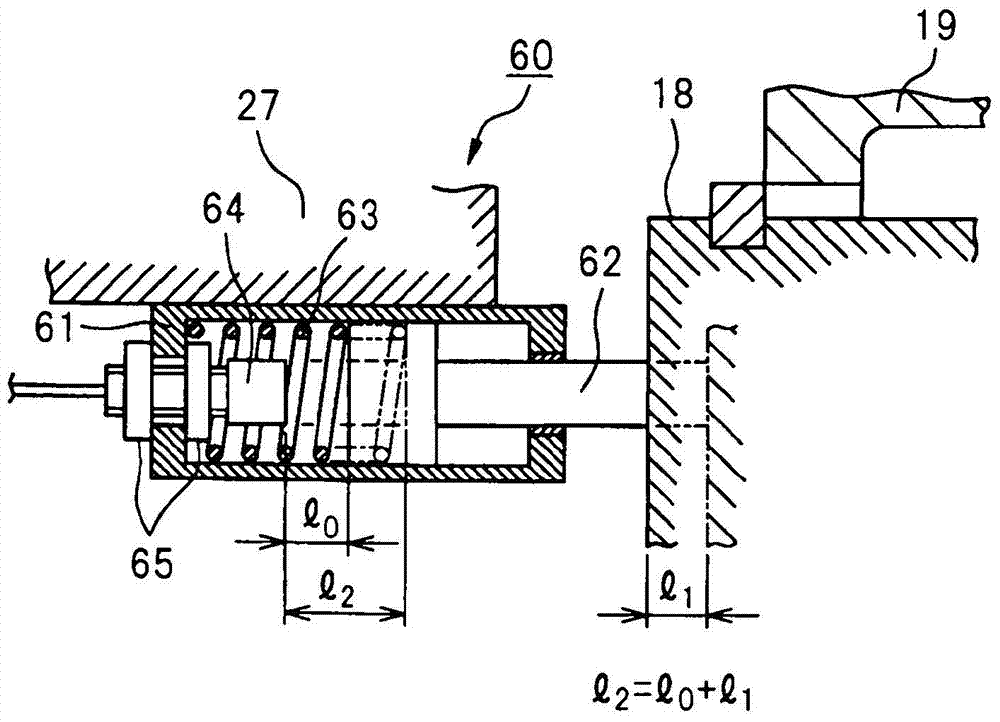

[0030] Such as figure 1 As shown in the extrusion machine, the end table 10 and the main hydraulic cylinder device 12 are arranged facing each other, and the two are connected by a plurality of tie rods 14 . The extrusion cylinder 18 is arranged on the inner surface side of the end table 10 so as to sandwich the female mold 16 with the extrusion hole formed therein. , the product of the cross section corresponding to the die hole 16A is extruded.

[0031] The main hydraulic cylinder device 12 that generates extrusion force has a main hydraulic head 12B built in the main hydraulic cylinder 12A so that it can push and move toward the above-mentioned extrusion cylinder 18 . The main crosshead 22 is attached to the front end of the main ram 12B, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com