Anti-blocking type gas filter

A gas filter and filter technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of general filtration effect, affecting work efficiency, and difficulty in cleaning filter elements, and achieves easy and labor-saving opening and operation. , to ensure the filtering effect, the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

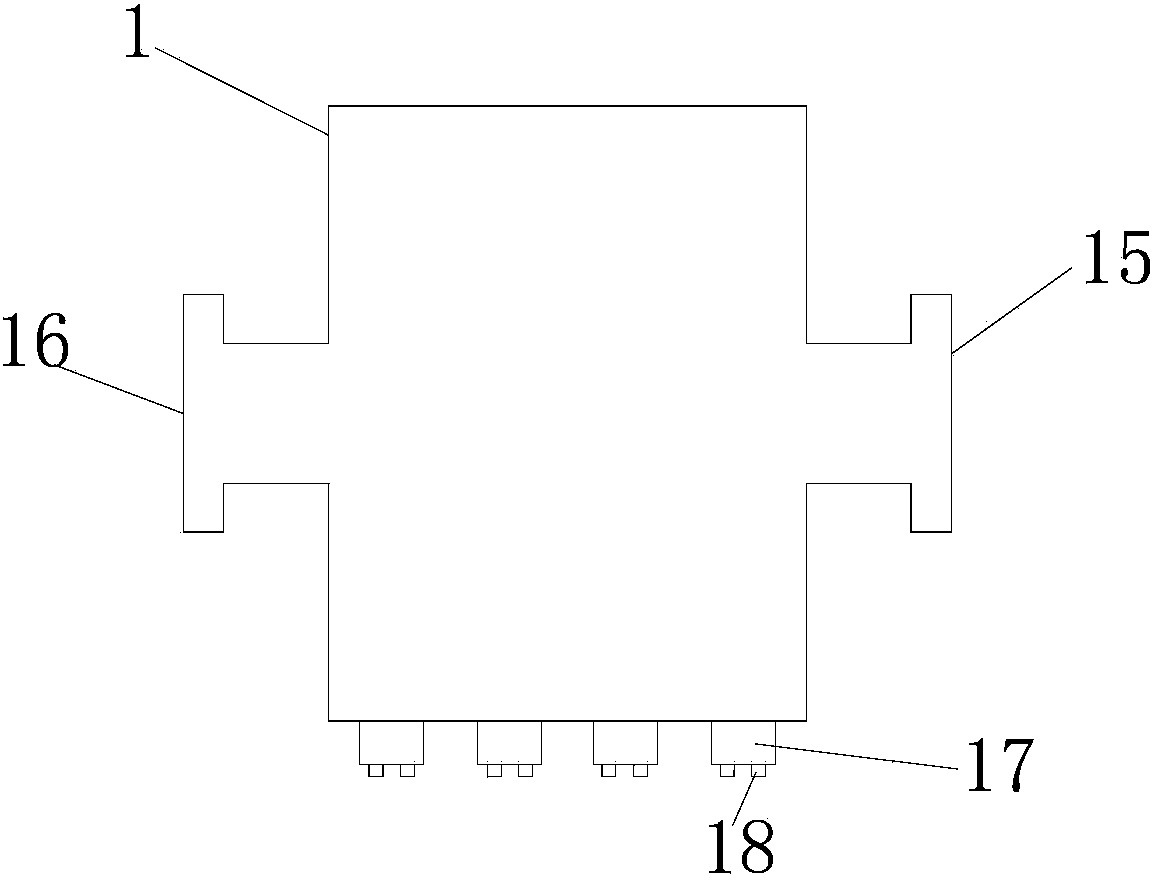

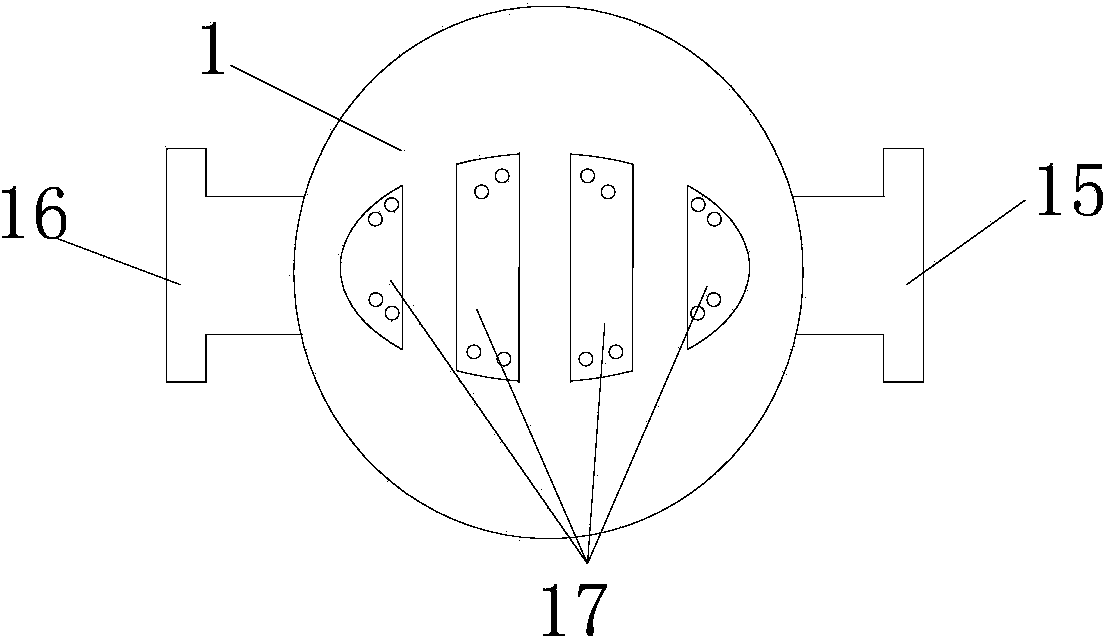

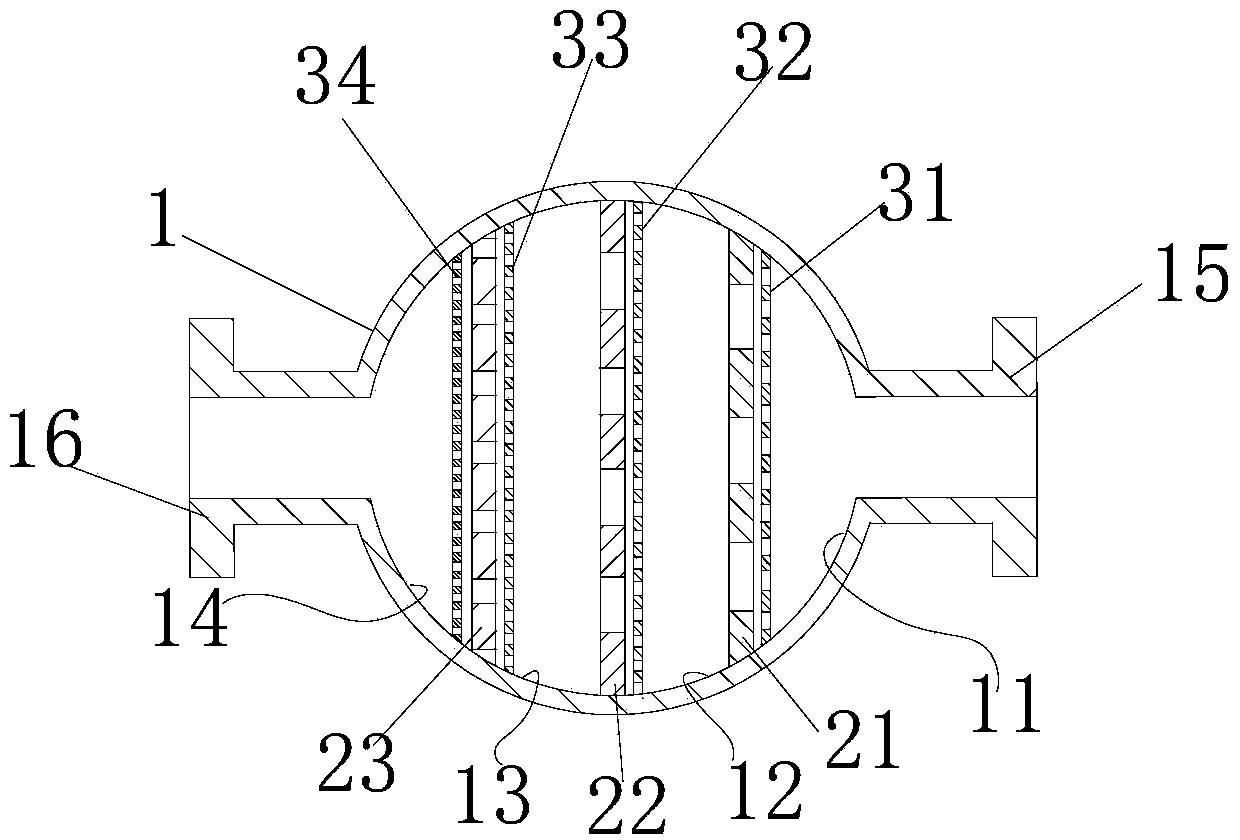

[0024] The invention provides an anti-blocking gas filter, which is provided with a cylindrical filter body, and the inner cavity of the filter body is sequentially provided with a first vertical sieve plate, a second vertical sieve plate and a third vertical sieve plate. To the sieve plate, the first vertical sieve plate, the second vertical sieve plate and the third vertical sieve plate are arranged at intervals along the radial direction of the filter body, so as to separate the inner cavity of the filter body in sequence It is the first chamber, the second chamber, the third chamber and the fourth chamber, and the first filter screen is placed correspondingly in the first chamber, the second chamber, the third chamber and the fourth chamber , the second filter net, the third filter net and the fourth filter net, and the number of meshes from the first filter net to the fourth filter net increases gradually, and the filter body corresponds to the first filter net The side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com