Automatic hole-drilling nail-locking machine for wood floor of container

A wooden floor and container technology, which is applied in the field of nail locking machines, can solve the problems of repeated operations, low production efficiency, and dense personnel, and achieve the effects of reducing the number of workers, improving efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0023] When the present invention describes the orientation, the length direction of the automatic drilling and locking machine is taken as the longitudinal direction, and the width direction of the automatic drilling and locking machine is taken as the transverse direction.

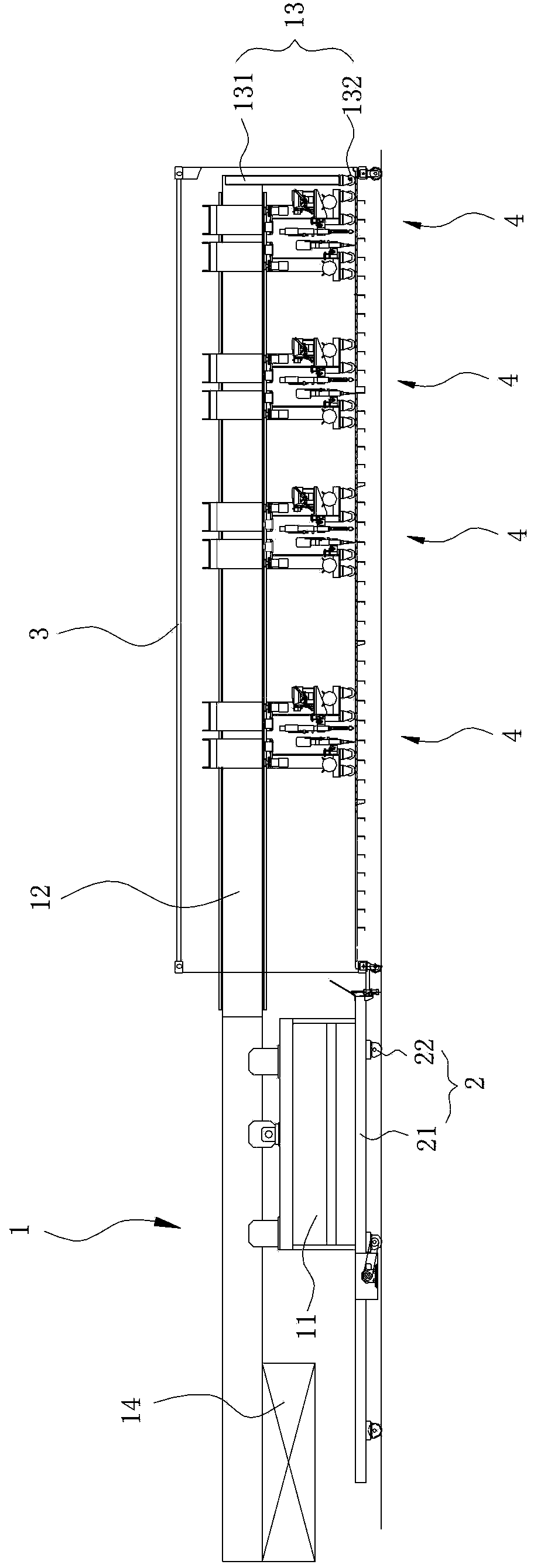

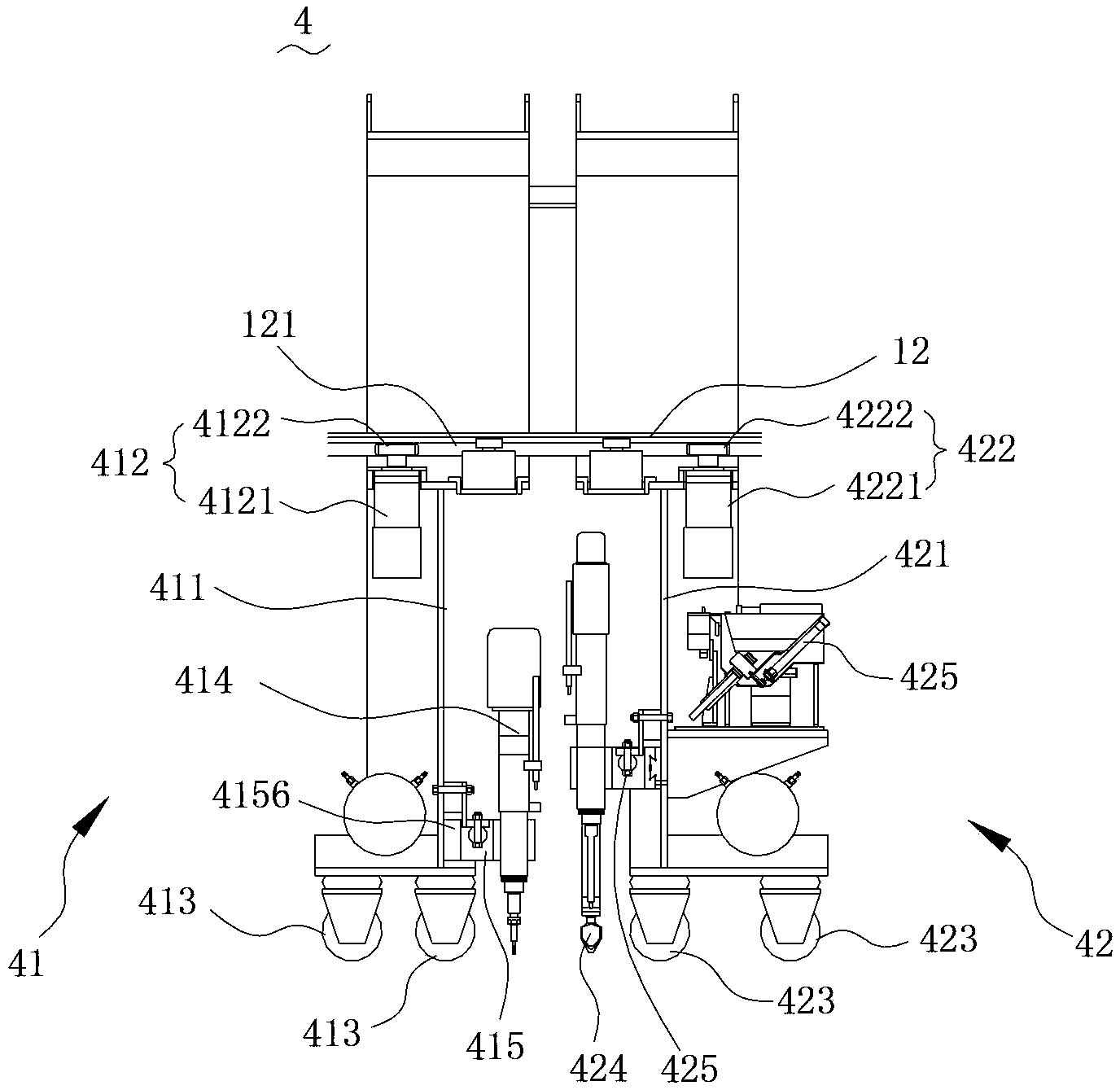

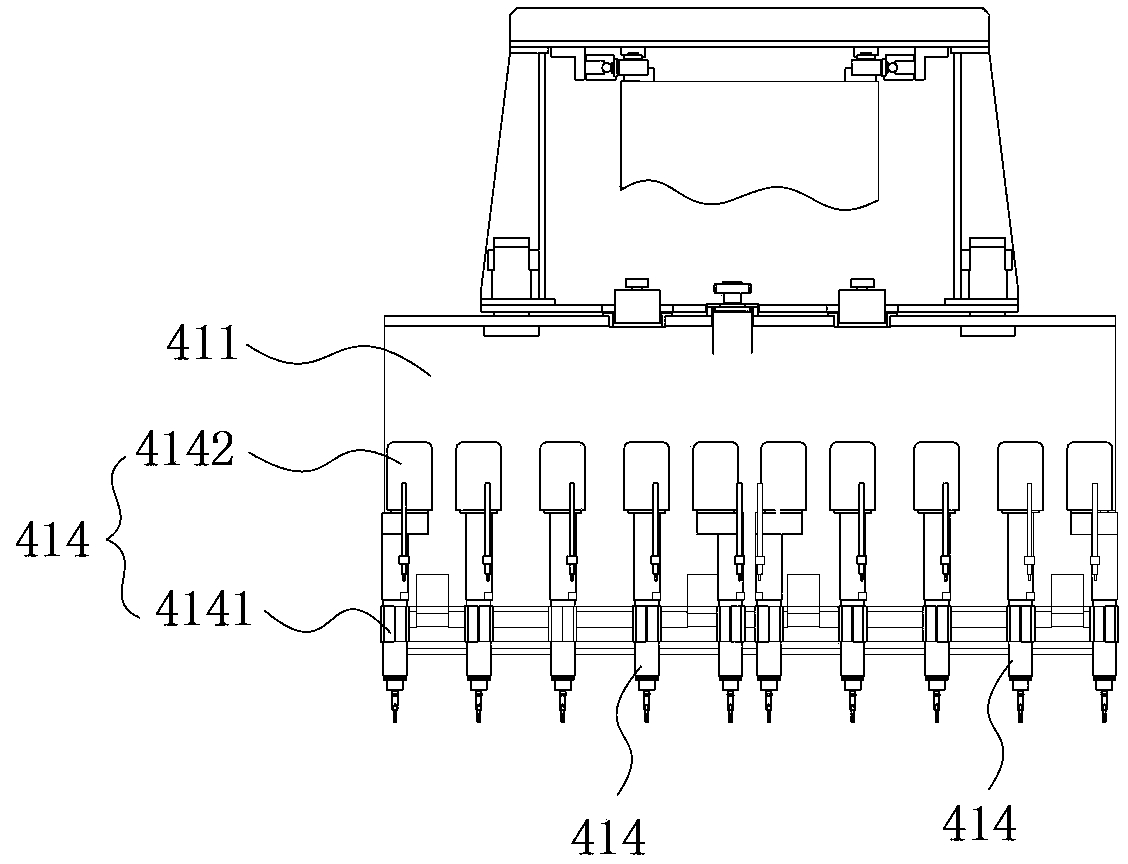

[0024] refer to figure 1 , The container wooden floor automatic drilling and nailing machine of the present invention includes: a main frame 1 and four sets of drilling and nailing mechanisms 4 . The main frame 1 includes: a base 11 , a beam 12 and an end support 13 . The crossbeam 12 protrudes from the base 11 in the longitudinal direction, a counterweight 14 is provided at one end thereof, and the other end is fixed by an end support 13 to keep the crossbeam 12 horizontal. The end suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com