Fan Component Forming Device

A molding device and component technology, applied in coating and other directions, can solve problems such as limited depth, limited number of metal components, and increased labor costs, and achieve the effects of improving quality, reducing water marks, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

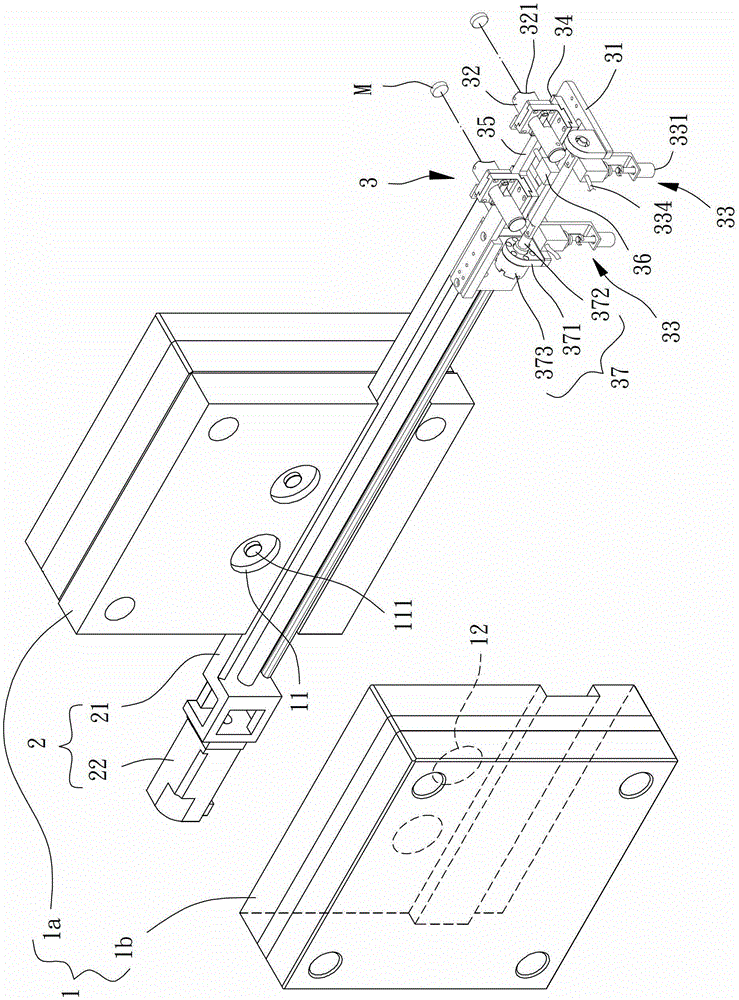

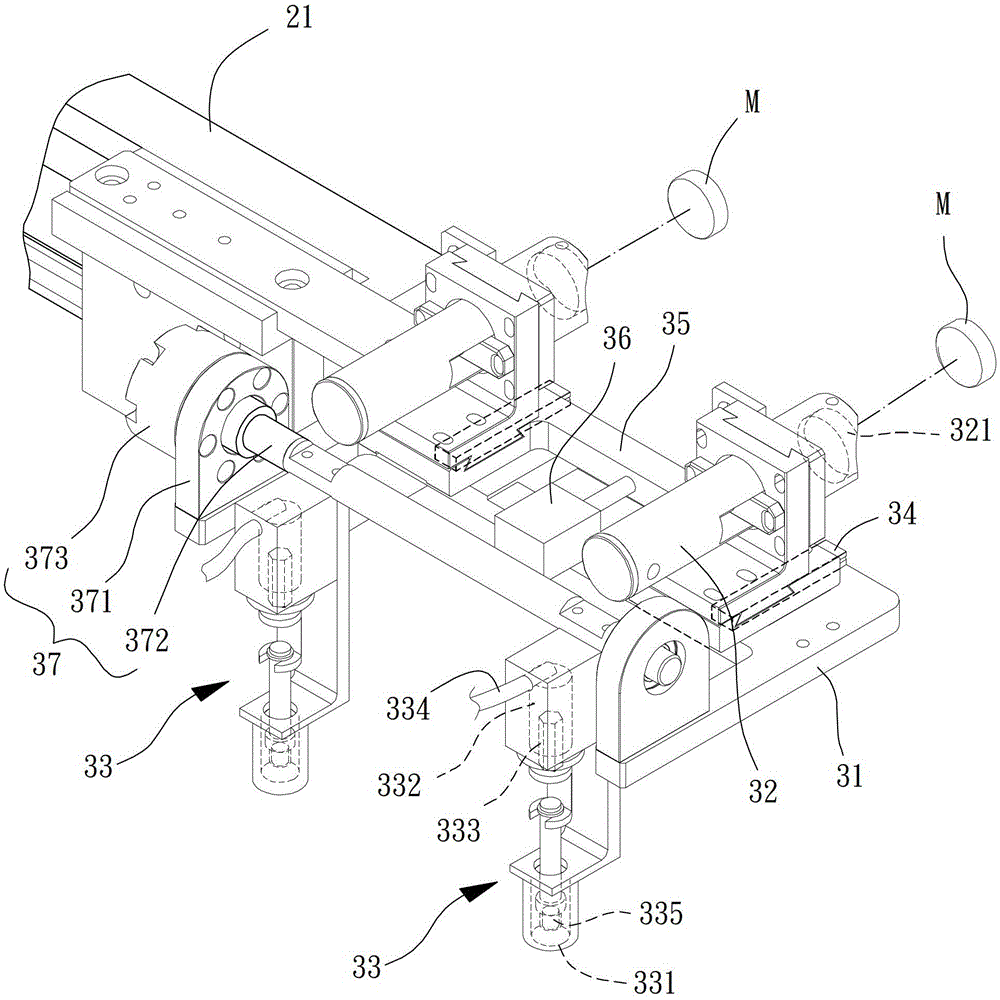

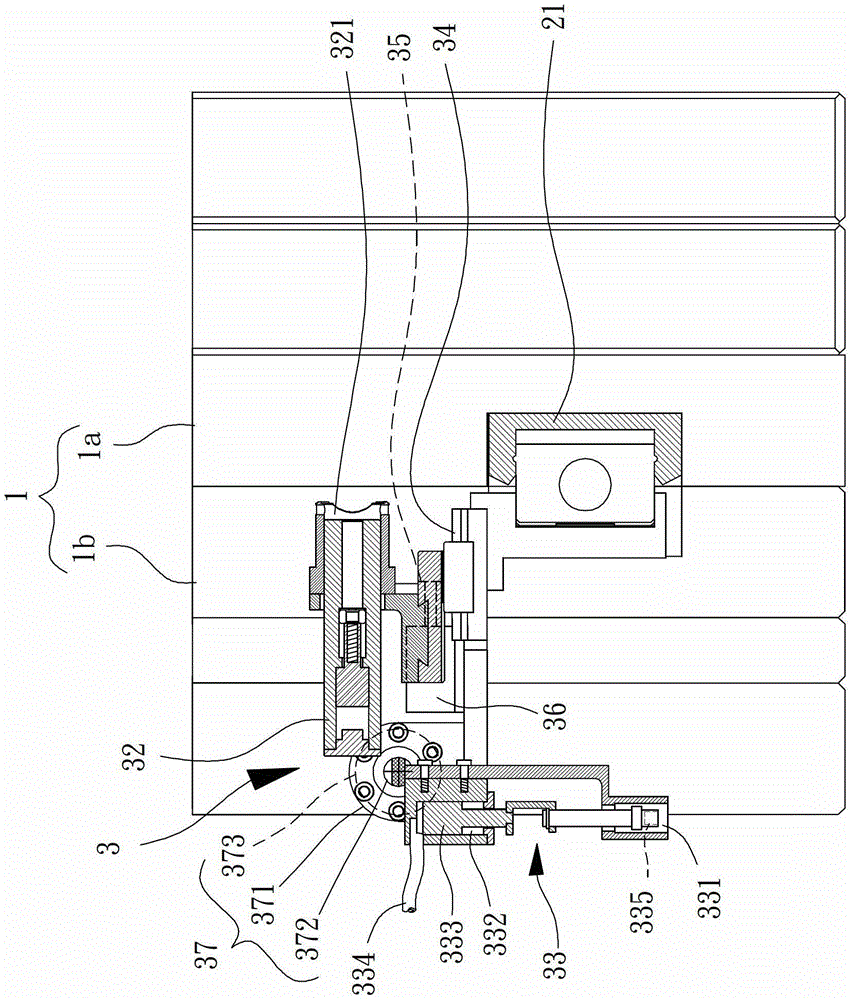

[0054] Please refer to figure 1 , which discloses a fan component forming device according to a preferred embodiment of the present invention. In this embodiment, the fan component forming device may include a mold set 1, a moving component 2 and a conveying component 3, and the moving component 2 is adjacent to the The mold set 1 and the conveying assembly 3 are movably arranged on the travel assembly 2 to move into or out of the mold set 1 . Wherein, the fan component molding device can be used to manufacture components composed of metal materials and plastic materials. For example, fan wheels comprising metal sealing magnets and plastic fan blades, fan frames comprising metal bottom plates and plastic side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com