Paper stacking method applied to paper processing device

A paper processing device and paper technology, applied in the field of stacking paper, can solve the problems of reducing the paper load capacity of the tray, paper stacking failure, labor-intensive finishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

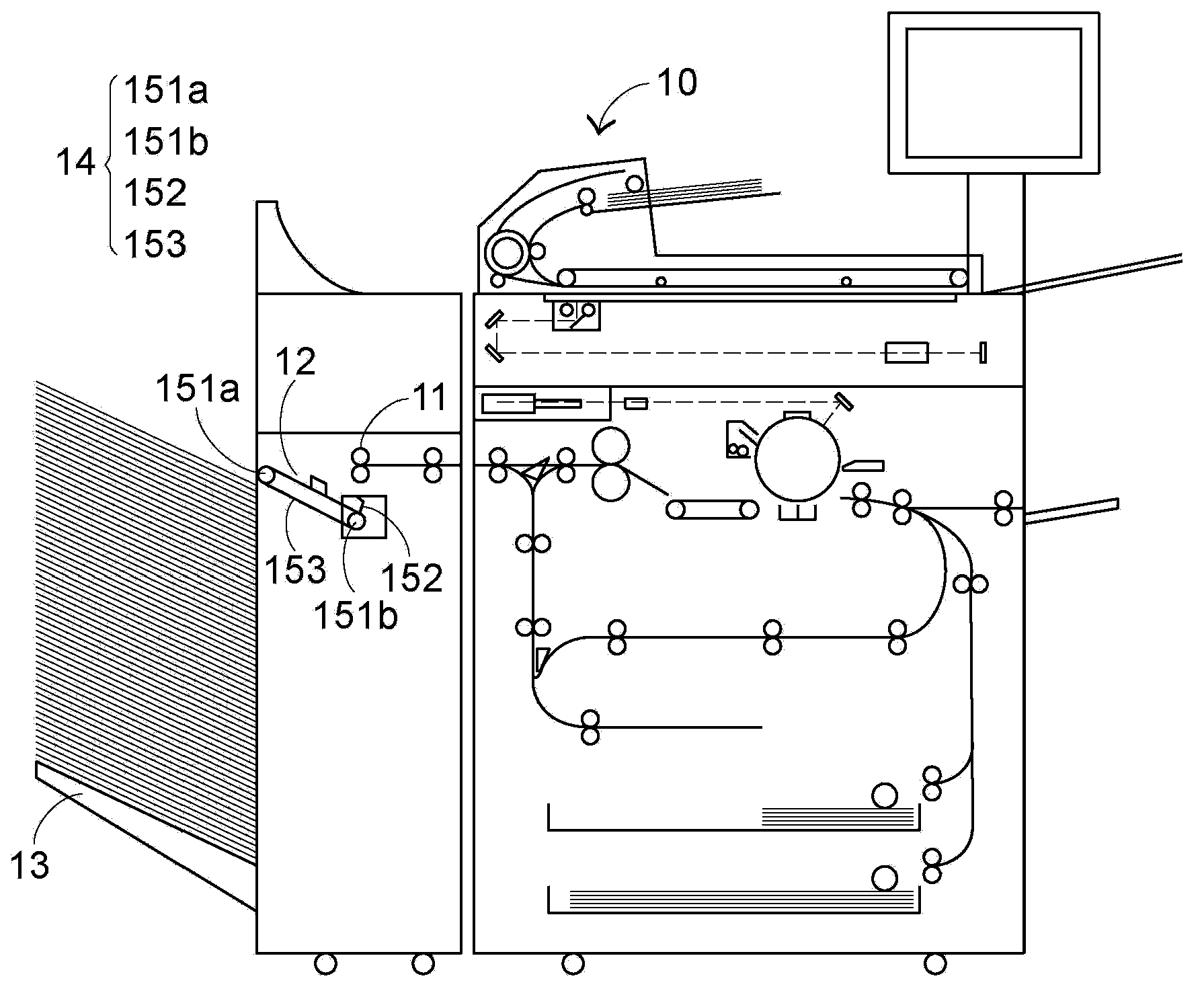

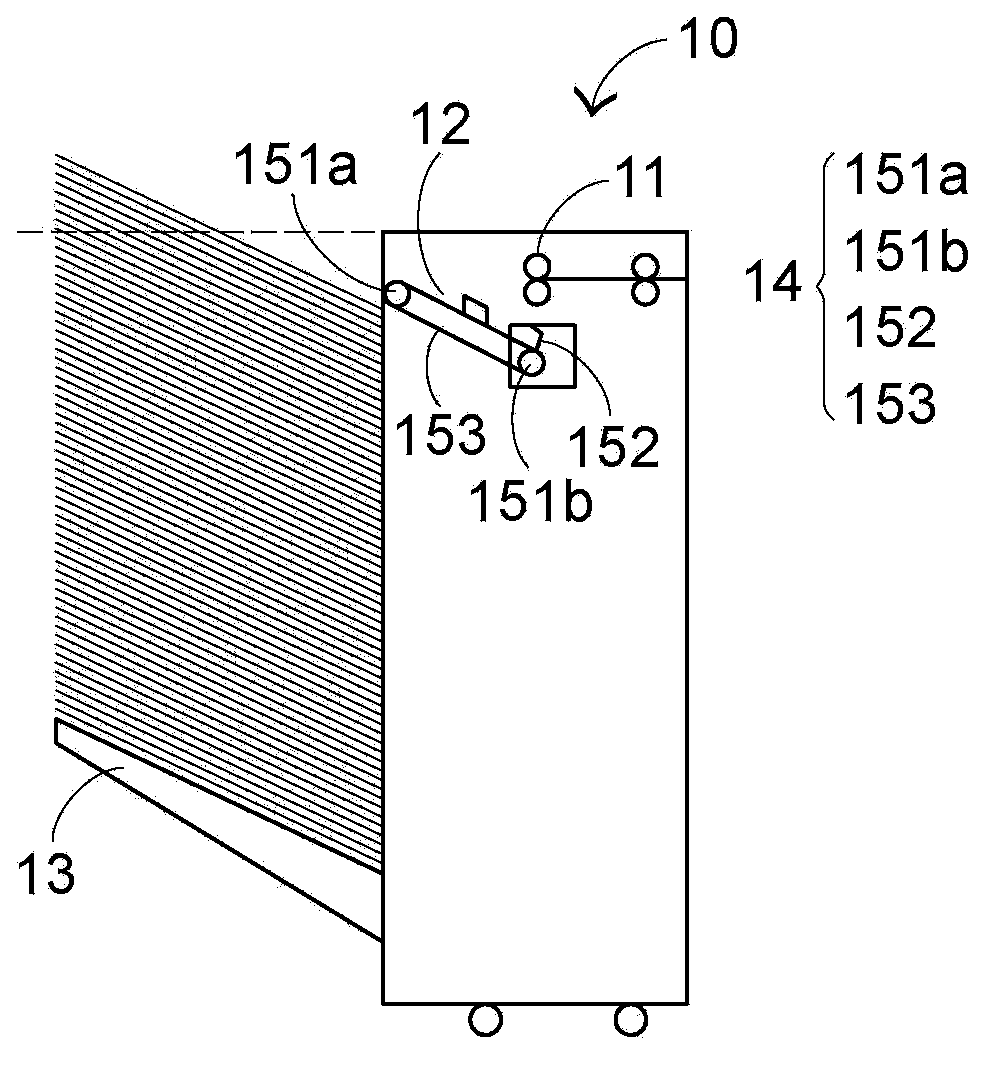

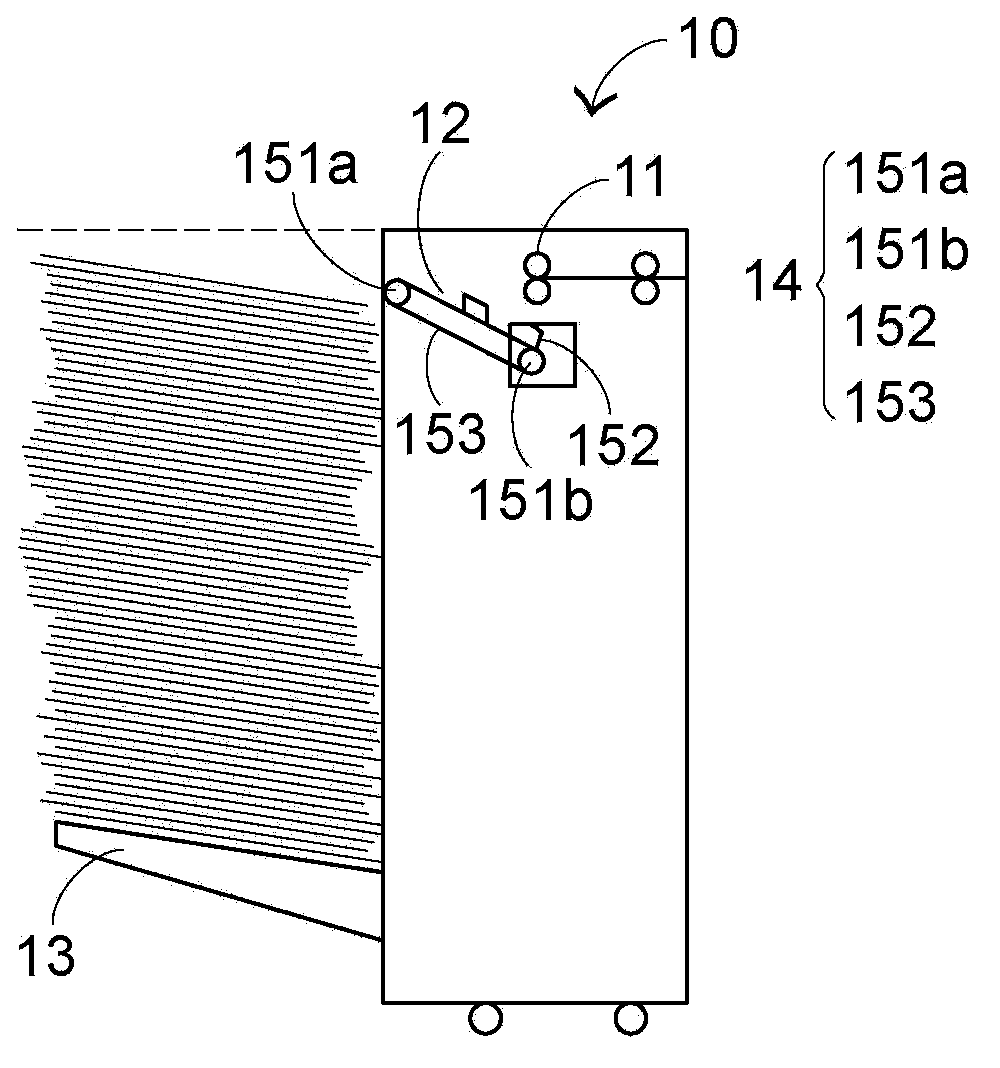

[0063] Please refer to Figure 4 and Figure 5 , Figure 4 is a schematic diagram of the first embodiment of the paper processing device of the present invention, Figure 5 It is a block diagram of the paper processing device of the present invention. like Figure 4 and Figure 5 As shown, the paper processing device 20 includes a platform 21, a paper tray 22, a transmission mechanism 23, a paper presser 24, a controller 25, a first sensor 26, a second sensor 27 and A third sensor 28 , wherein the first sensor 26 , the second sensor 27 and the third sensor 28 are electrically connected to the controller 25 for sending an electrical signal to the controller 25 . In addition, the controller 25 is electrically connected to a power source (not shown in the figure), such as a DC motor, for driving the paper tray 22 and the transmission mechanism 23 .

[0064] read on Figure 4 . The platform 21 is located at the paper outlet of the paper processing device 20 , and is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com