An automatic environmental protection truck loading system for bagged bulk materials

A technology for packaging bags and bulk materials, which is applied in the field of automatic environmental protection truck loading systems for bagged bulk material packaging bags, can solve problems such as failing to meet standard requirements, avoid direct contact with dust environment, reduce the needs of operation and handling, and avoid diffusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to understand the content of the present invention more clearly, it will be described in detail with reference to the drawings and embodiments.

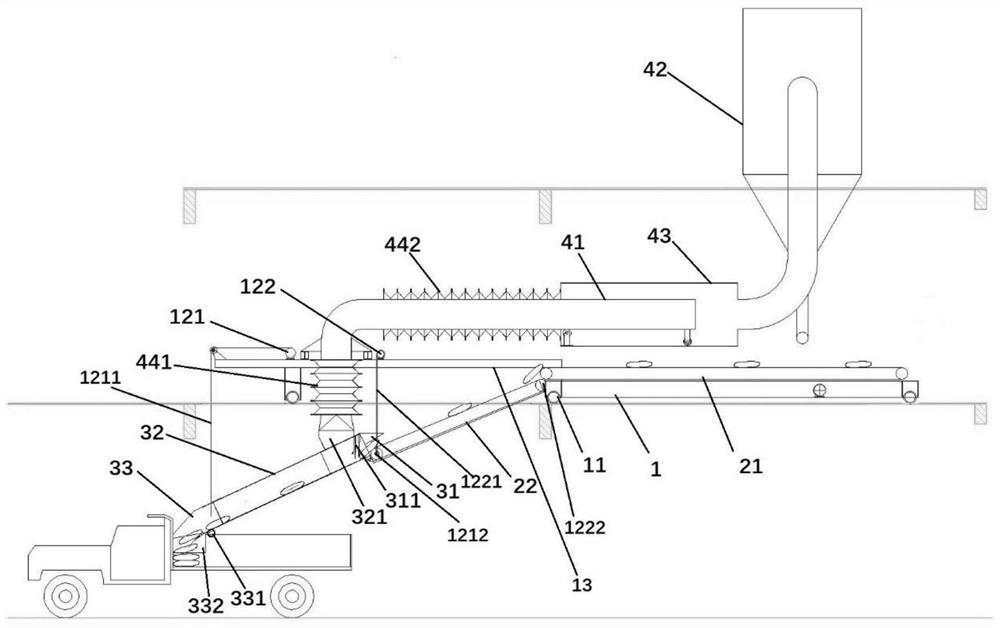

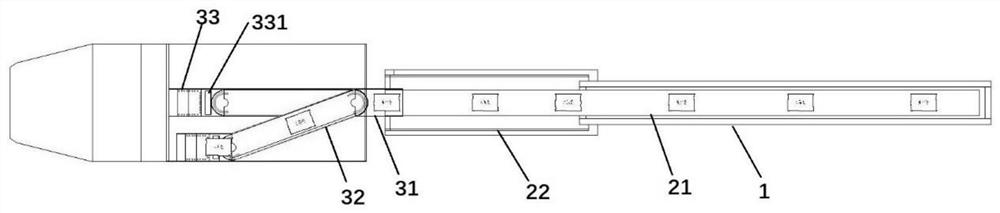

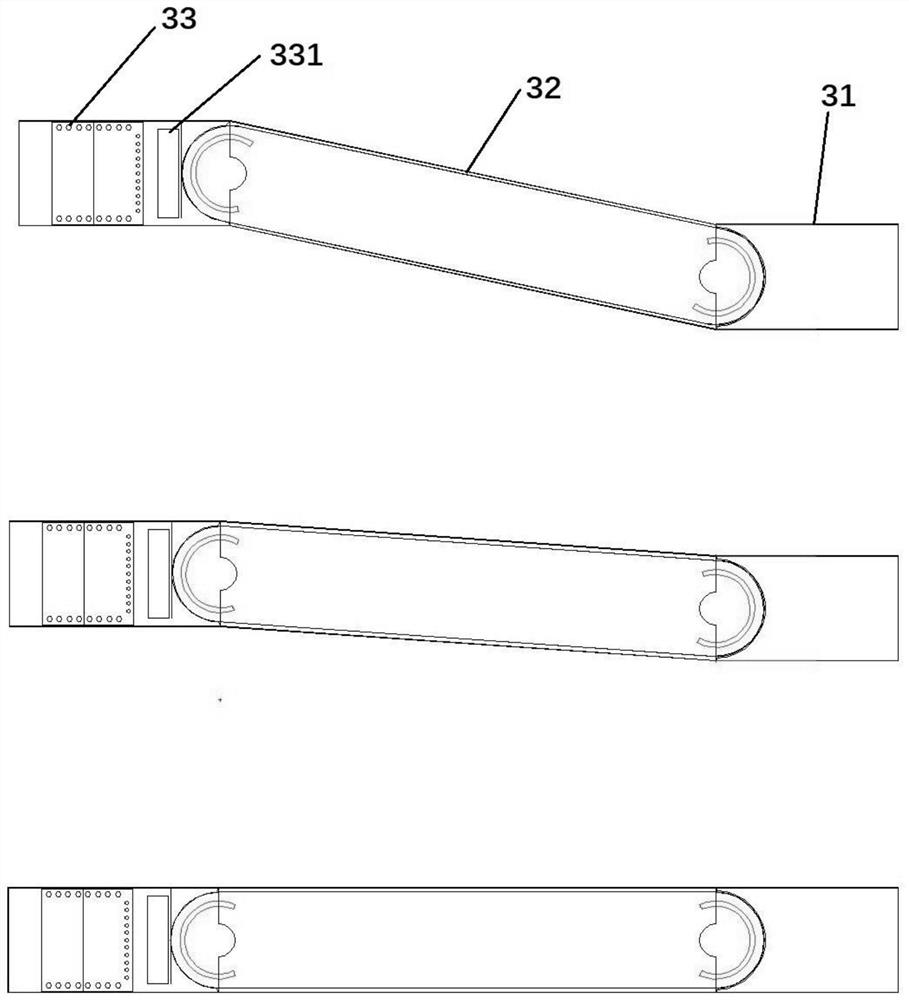

[0035] Such as figure 1 Shown is a schematic structural diagram of the automatic environmental protection loading system of bagged bulk material packaging bags of the present invention, including a support structure 1, a conveyor belt structure, a serpentine pipe, and a dust suction structure; The trolley 11 and the serpentine tube lifting and storage device fixed on the support 13 are composed of a serpentine tube lifting hoist 121 and an inclined belt conveyor lifting hoist 122. The trolley has a moving track and moves horizontally. The lifting and storage device is located above the serpentine tube as a whole; the inclined belt lifting hoist rope 1221 driven by the inclined belt lifting hoist 122 is fixedly connected to the end of the inclined belt conveyor 22 or close to the end position and passes through the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com