A kind of disperse black dye composition for superfine fiber

A dye composition and ultra-fine fiber technology, applied in the field of dyes, can solve the problems of dye migration to the surface, reduced wet treatment fastness, and high fiber amorphous content, and achieve the effects of good dye depth and high washing fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

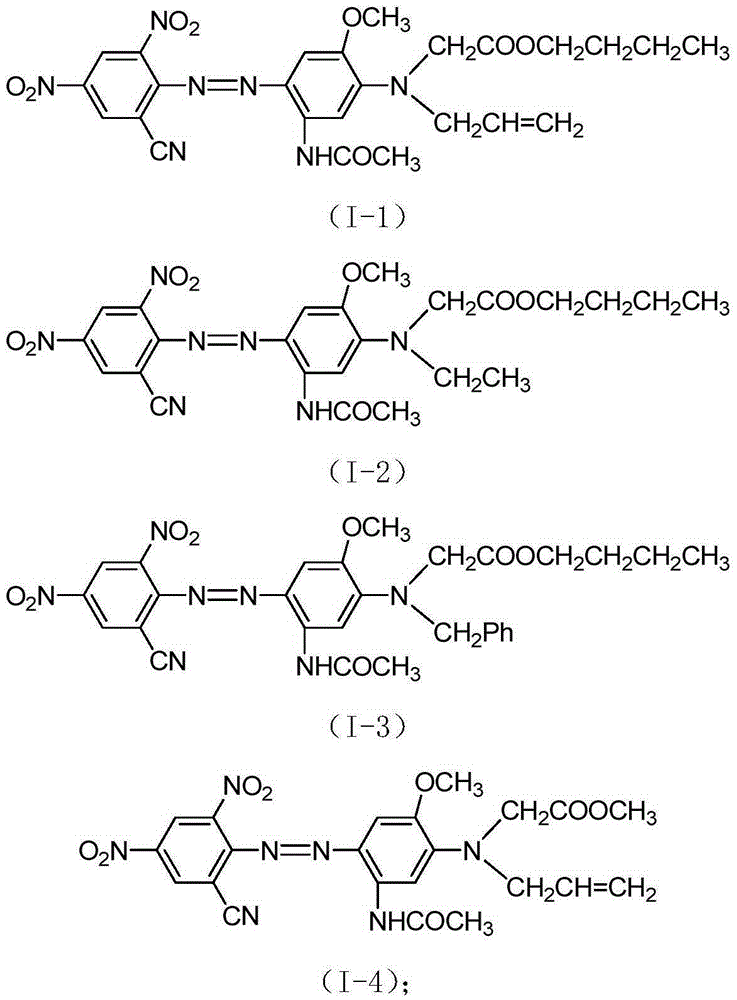

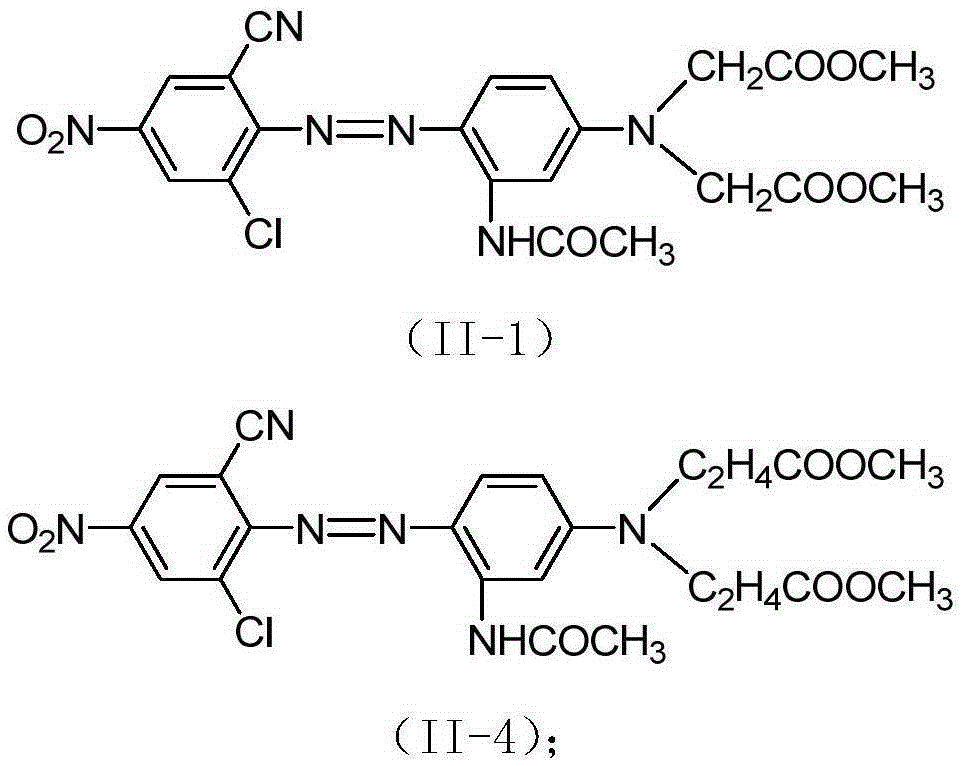

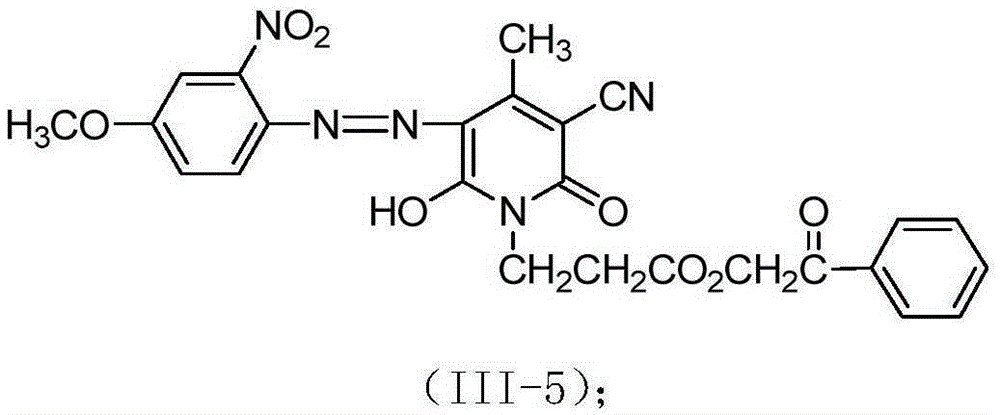

[0034] With the disperse blue dye (component A) 40g shown in I-1, the disperse violet dye (component B) 10g shown in II-2, the disperse yellow dye (component C) 10g shown in III-1, IV Disperse yellow dye (component D) 10g shown in -3, 30g of dispersant 85A (sodium lignosulfonate) is added in 200g water, after continuous grinding, after spray drying, the finished product packaging obtains the disperse black dye composition for superfine fiber .

Embodiment 2-15 and comparative example 1-3

[0036] According to the ratio shown in Table 1, other operations are as in Example 1.

[0037] Table 1

[0038]

[0039]

Embodiment 16

[0041] Get the disperse dye that above-mentioned embodiment 1-15 and comparative example 1-4 make carry out printing and dyeing property test, test method is as follows:

[0042] Each get the disperse dye that 0.5g embodiment 1-15 and comparative example 1-4 make, make the disperse dye suspension that concentration is 1.0g / L respectively with water, get 20mL disperse dye suspension and mix with 80mL water, wash with acetic acid Adjust the pH to 4.5-5.0, then raise the temperature to 60°C, add 2g of polyester microfibers for dyeing, raise the temperature to 130°C within 35 minutes, keep the temperature for 30 minutes, and take samples when cooled to 80°C. Observe the shade of the cloth sample and measure its color fastness using GB / T3921, GB / T3920-1997, GB / T5718-1997, and measure the dye uptake rate by GB / T9337-2009. The measurement results are shown in Table 2

[0043] Table 2 Units: Grade

[0044]

[0045]

[0046] The three components A, B, C, and D of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com