A kind of lithium-ion battery assembly method

A lithium-ion battery, battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., to achieve the effects of excellent efficiency, high capacity, and large depth of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments.

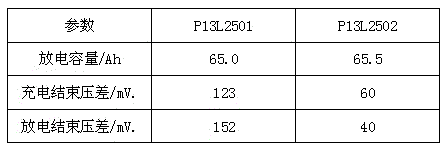

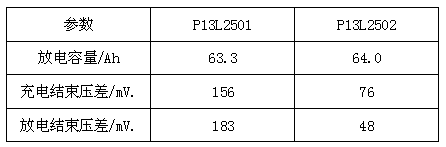

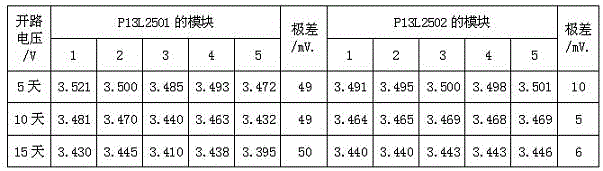

[0018] Take the produced IFP1965140 model 13L25 batch capacity range of 12.8-13.5Ah fully charged battery cells 1# box and 2# box, 80 each, and it is required to form 5 parallel battery packs. According to the traditional grouping method and the grouping method of the present invention, a group of battery packs are respectively equipped for detection. Wherein the number of the battery pack made by the traditional matching method is P13L2501, and the number of the battery pack made by the matching method of the present invention is P13L2502, the process and test data are as follows:

[0019] Traditional matching method P13L2501 matching process:

[0020] Conduct voltage test on 80 batteries in 2# box, pick out 2 batteries with open circuit voltage lower than 3.340V, then conduct internal resistance test, pick out 1 battery with internal resistance greater than 6mΩ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com