Combined chord tangent dust fog removal device

A technology of cutting strings and devices, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large pressure loss, inability to achieve dust removal effect, and low removal efficiency of small-diameter droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

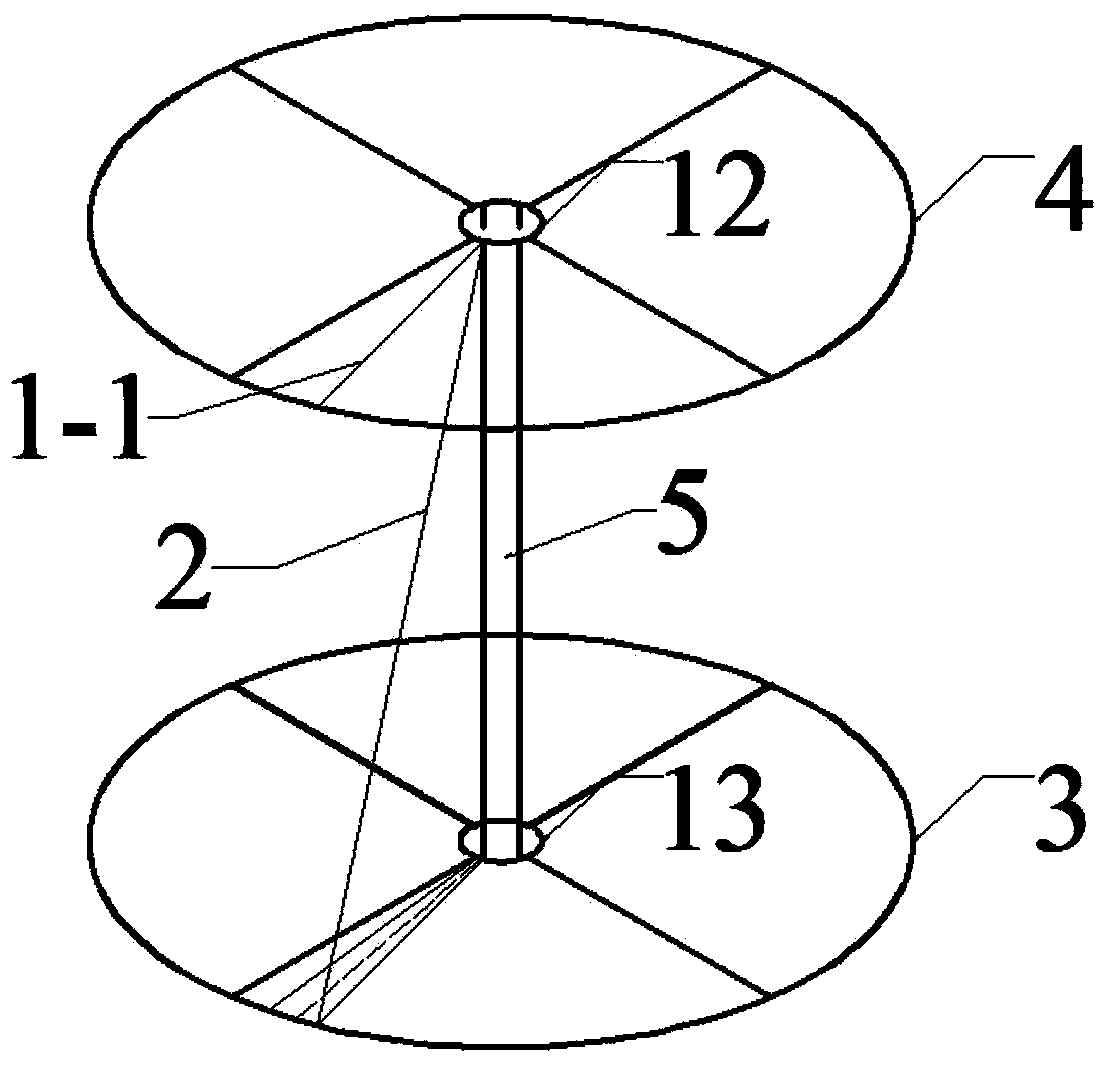

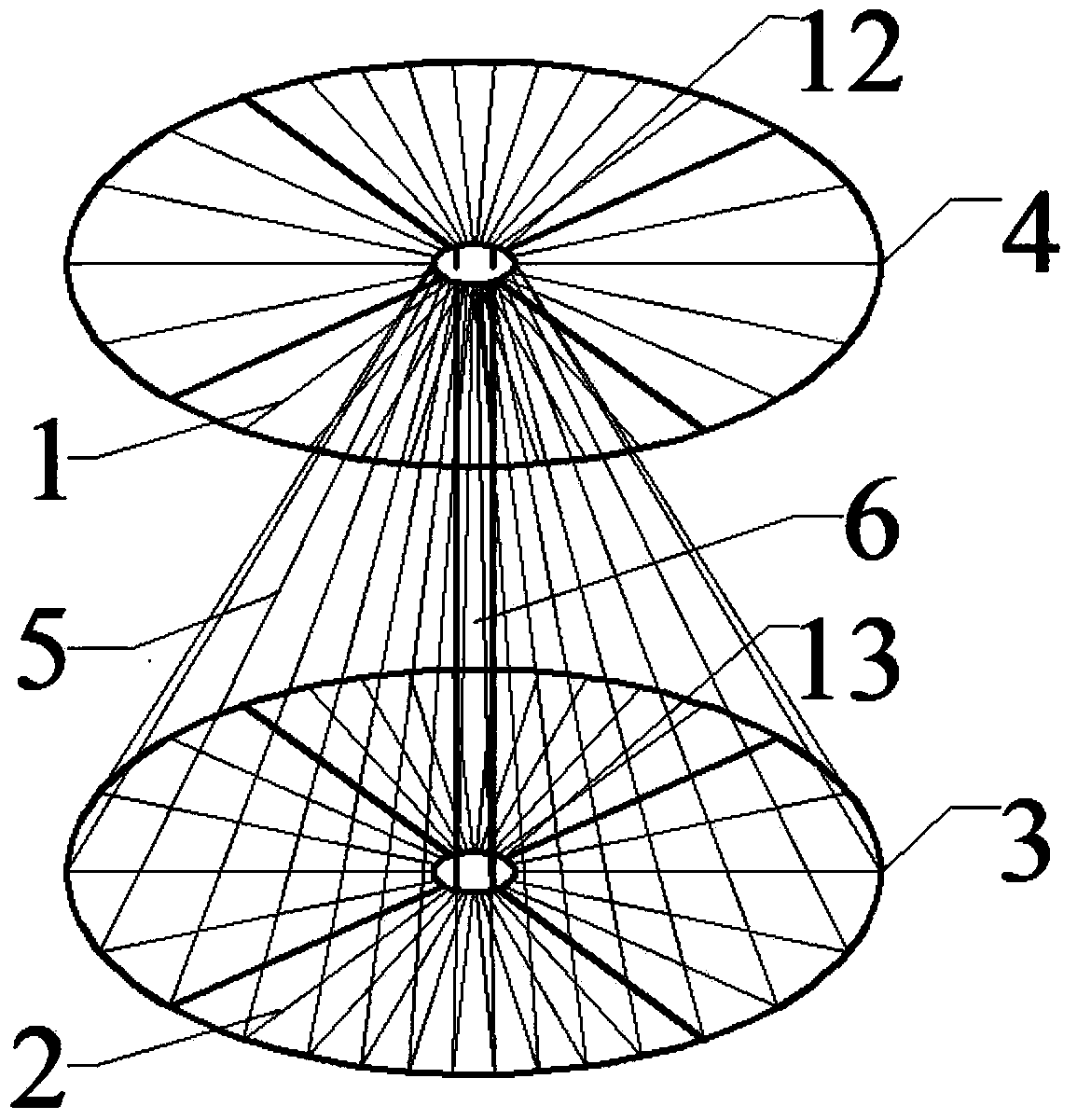

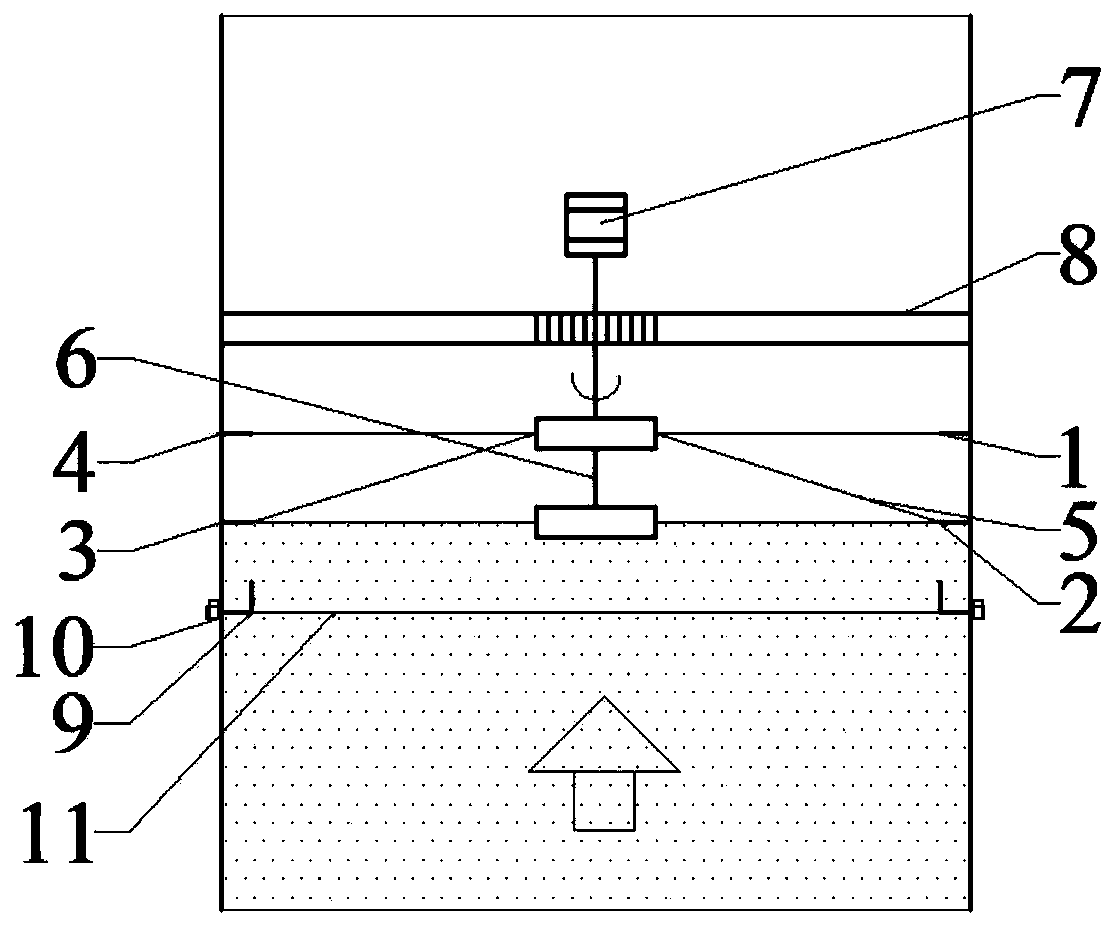

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as image 3 The combined cut-string dedusting and mist removal device shown in the figure includes a dust and mist removal device, a motor 7, a motor support ring 8, a water collection tank 9, a drain valve 10, and an intercepting net 11. The connection in the dust and mist removal device One end of the shaft 6 tail is connected with the motor 7 through a bearing, and the end of the connecting shaft 6 tail is the end in the downwind direction, and the installation of the motor 7 in the downwind direction helps reduce resistance and improve the service life of the motor.

[0022] The motor 7 is fixed on the motor support ring 8, and the motor support ring 8 is fixed in the cylinder body. A water collection tank 9 is arranged on the cylinder body at a certain distance from the lower end of the dust and mist removal device, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com