Braking torque self-detecting circuit for elevator brake

A technology for elevator brakes and braking torque, applied in the direction of force/torque/power measuring instruments, instruments, measuring devices, etc., which can solve the problems that the braking torque cannot be detected, the braking torque self-test function cannot be realized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

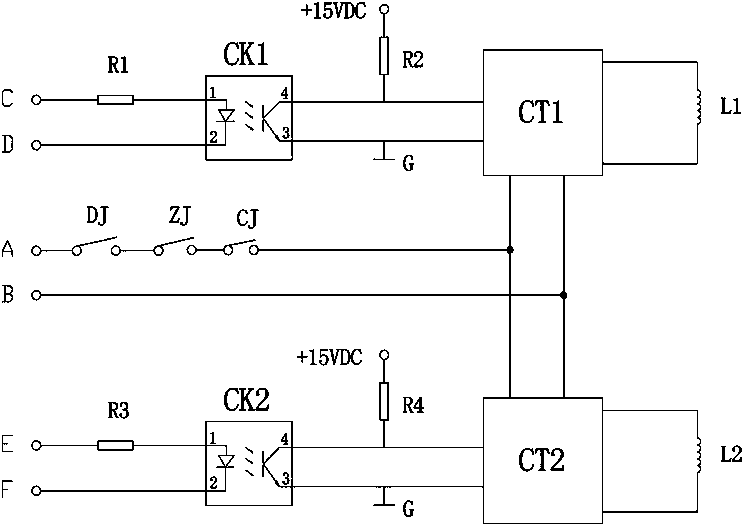

[0018] This embodiment is aimed at the circuit structure configured by dual brake controllers. Such as figure 1 As shown, the input terminals of the two brake controllers CT1 and CT2 are connected to the brake circuit (the two terminal points of the brake circuit are marked as A and B), and the door lock relay DJ and the brake relay are connected in series in the brake circuit. Gate relay ZJ and run contactor CJ. The working voltage of the brake circuit is applied to both ends of A and B, and the voltage can be AC 110 / 220V or DC 110 / 220V.

[0019] The output terminals of the two brake controllers CT1 and CT2 are respectively connected to an electromagnetic coil L1 and L2. Control terminals are respectively provided on the two brake controllers CT1 and CT2 to control the actions of the brake controllers. Connect a level control loop to the control terminals of the two brake controllers CT1 and CT2 (the two terminal points of one level control loop are marked as C and D, an...

Embodiment 2

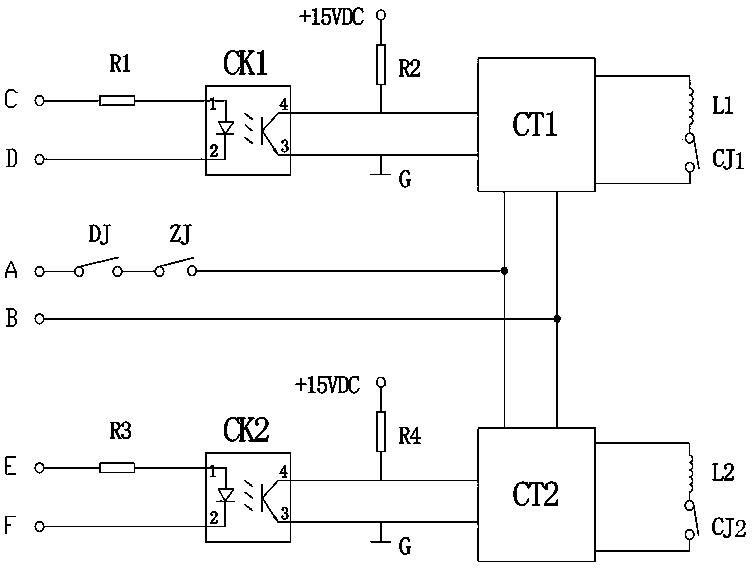

[0025] This embodiment is also aimed at the circuit structure configured by dual brake controllers. Such as figure 2 As shown, its circuit structure and working principle are basically the same as that of Embodiment 1, the difference is that the running contactor CJ is removed from the brake circuit and becomes two, which are respectively set in the circuits of the electromagnetic coils L1 and L2 , that is, after the electromagnetic coil L1 is connected in series with the running contactor CJ1, and the electromagnetic coil L2 is connected in series with the running contactor CJ2, they are respectively connected to the output ends of the corresponding brake controllers CT1 and CT2.

Embodiment 3

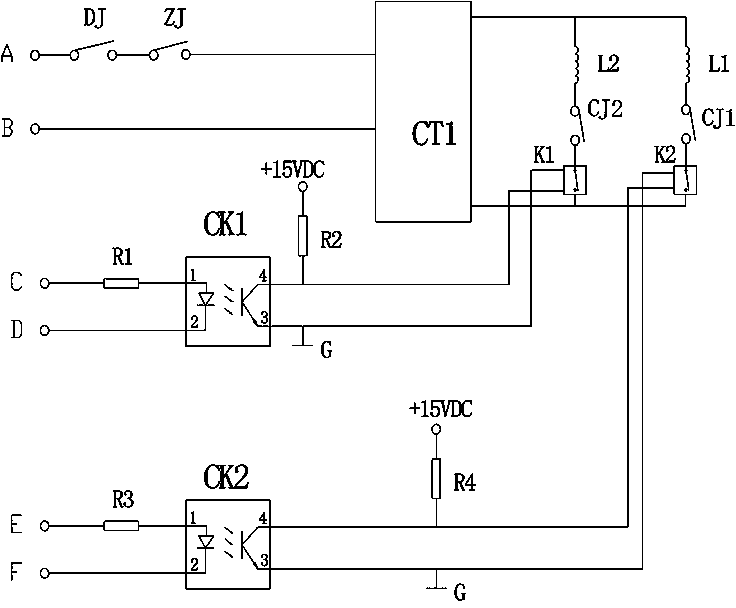

[0027] This embodiment is for a circuit structure configured with a single brake controller. Such as Figure 4 As shown, the brake circuit is connected to the input end of the brake controller CT1 (the two terminals of the brake circuit are marked as A and B), and the brake controller CT can adopt a conventional control circuit structure. A door lock relay DJ, a brake relay ZJ and a running contactor CJ are connected in series in the brake circuit. The working voltage of the brake circuit is applied to both ends of A and B, and the voltage can be AC 110 / 220V or DC 110 / 220V.

[0028] Two electromagnetic coils L1, L2 connected in parallel are connected to the output terminal of the brake controller CT1. A control switch K1, K2 is connected in series on each electromagnetic coil branch, and a level control loop is respectively connected to the action control ends of the two control switches K1, K2 (the two terminal points of a level control loop are marked as C, D, the two t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com