Fracturing string with step-by-step setting and perforation and method of using the same

A fracturing string and perforation technology, which is applied in the field of fracturing strings, can solve the problems of unrealistic fracturing construction, limited fracturing fluid pump injection, and increased oil and gas production costs, and achieve control of oil and gas production costs, pumps, etc. The effect of large injection and drainage volume and improving the efficiency of fracturing construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

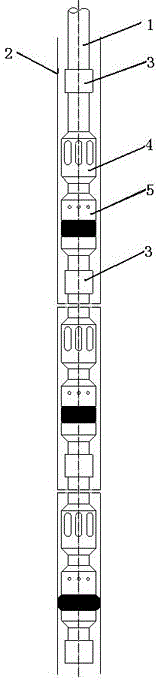

[0024] see figure 1 : The present invention includes three fracturing sliding sleeves 4 and three spray-sealing integrated tools 5. Each fracturing sliding sleeve 4 corresponds to a spray-sealing integrated tool 5, the top of the fracturing sliding sleeve 4 is connected to the tubing 1 through a coupling 3, the bottom end of the fracturing sliding sleeve 4 is connected to the top of the spray-sealing integrated tool 5 Through threaded connection, the bottom end of the spray-sealing integrated tool 5 is connected with the oil pipe 1, and the fracturing sliding sleeve 4 and the spray-sealing integrated tool 5 are used as a pair. In this way, three pairs of supporting fracturing sleeves 4 and spray-sealing integrated tools 5 are axially connected in series on the tubing 1 to form a three-stage fracturing string. When in use, the fracturing string Go down into casing 2.

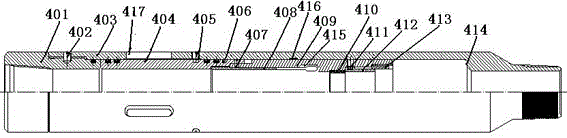

[0025] see figure 2 : The above-mentioned fracturing sliding sleeve 4 is mainly composed of an upper joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com