Coupling for pumping unit

A technology of coupling and pumping unit, applied in the direction of coupling, elastic coupling, mechanical equipment, etc., can solve the problems of many parts, poor sealing, troublesome disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

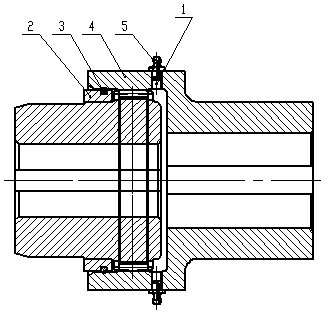

[0010] The shaft coupling for pumping unit of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] As shown in the figure, the coupling for oil pumping unit of the present invention includes two coupling halves respectively connected to the two rotating shafts, wherein the end of one coupling half is set as a connecting sleeve 4 with internal teeth, The outer circumference of the end of the other half-coupling is provided with external teeth that match the internal teeth of the connecting sleeve. The said external teeth are drum-shaped teeth. The shaft formed by this half-coupling with external teeth is called It is an external gear shaft. After the connecting sleeve 4 is set on the external teeth, a sealing sleeve 2 located behind the external teeth seals the external teeth in the connecting sleeve 4. The inner diameter of the sealing sleeve 2 and the outer diameter of the external gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com