Energy-saving and high-efficiency micropower dust removing device and method

A technology of dust removal device and dust suction fan, which is applied in the field of dust removal device in the process of belt conveying materials, to achieve the effect of enhancing dust removal effect and saving energy

Active Publication Date: 2014-06-04

DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the defects of existing industrial micro-power dust collectors, the present invention proposes an energy-saving and high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

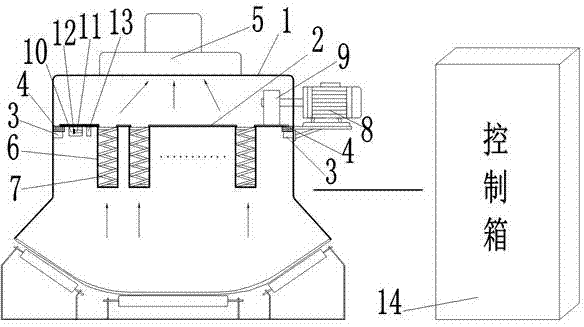

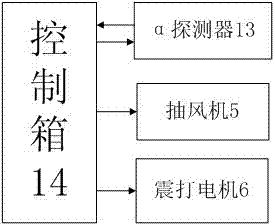

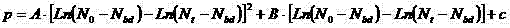

The invention relates to an energy-saving and high-efficiency micropower dust remover which is capable of adjusting power according to the amount of dust with respect to a process of conveying a material through a belt. Through matching an alpha ray source and an alpha detector, the amount of flying dust is detected when the material is conveyed through the belt, and the rotating speed of a dust collecting fan is controlled based on the detection. According to the energy-saving and high-efficiency micropower dust remover, the rotating speed p of the dust collecting fan can be adjusted in real time so that the effects of increasing the rotating speed p of the dust collecting fan to enhance the dust removing effect when dust is oversized and reducing the rotating speed p of the dust collecting fan to save energy resources when the dust is undersized are achieved.

Description

technical field [0001] The invention relates to an industrial dust removal device and method, in particular to a dust removal device and method in the process of belt conveying materials. Background technique [0002] In industrial and mining enterprises, many materials need to be transported by belts for long distances, because the length of the belt is limited, and one belt can only be transported in a straight line, so in practice, several belts are often required for multi-stage transfer. In order to avoid and eliminate the dense dust generated during the transfer process at all levels, all kinds of dust removal equipment are used, mainly including bag type dust collector, high voltage electrostatic dust collector, water bath dust collector, etc. Due to the specific working methods of high-voltage electrostatic dust collectors and water-bath dust collectors, the application fields are narrow. At present, the most widely applicable fields are micro-power dust collectors w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D46/06B01D46/04B01D46/44

Inventor 张伟佟超刘正业史振奎杨学谦丛浩杰苟强源蒋宝庆林春强霍亮康博赵洪涛王选涛毕文王群

Owner DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com