Inspection method of spark plug and manufacturing method of spark plug

一种检查方法、火花塞的技术,应用在火花塞制造、火花塞、火花隙的调整等方向,能够解决不能判别、成品率下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

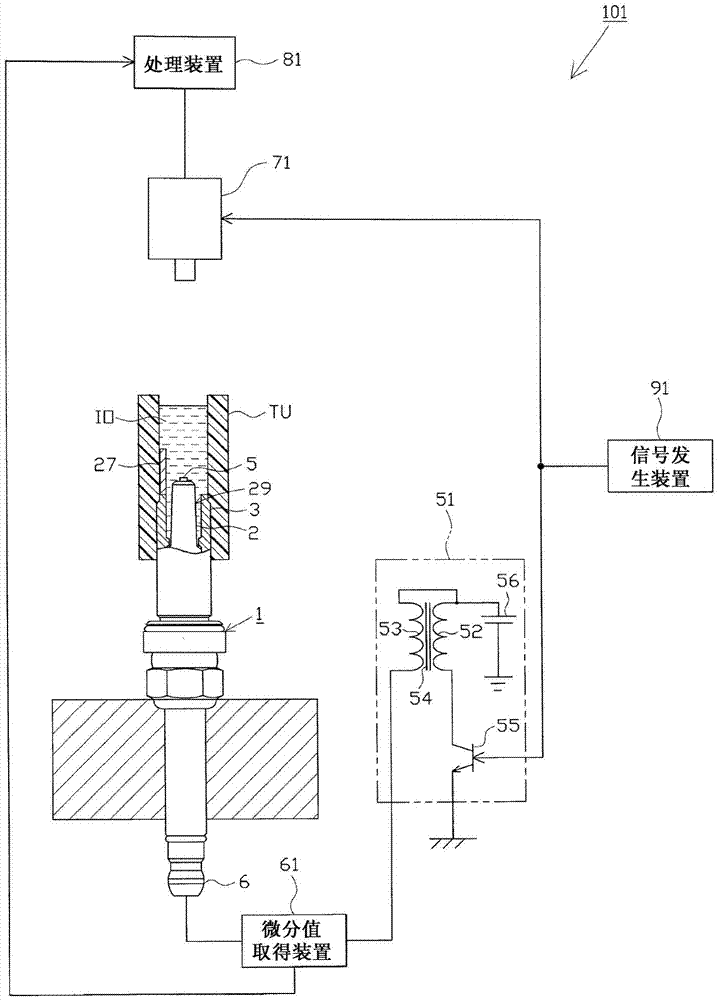

[0083] Next, an embodiment will be described with reference to the drawings. figure 1 It is a schematic diagram showing a schematic configuration of the inspection device 101 for the spark plug 1 . The inspection device 101 is a device used when inspecting the insulation performance (withstand voltage performance) of the insulator 2 described later in the manufacturing process of the spark plug 1 .

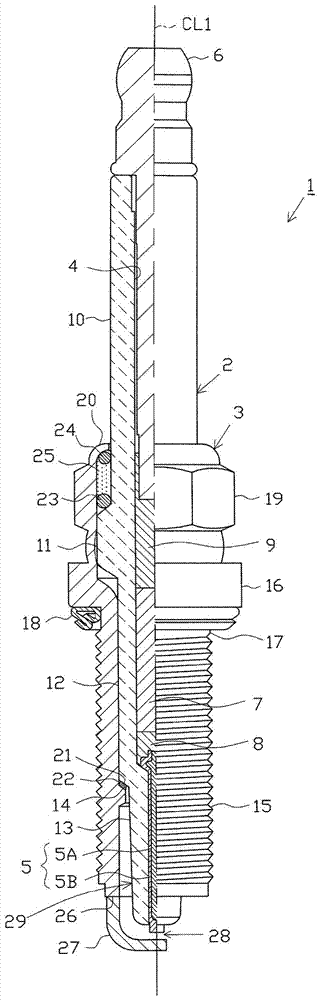

[0084] First, before describing the inspection device 101, the structure of the spark plug 1 to be inspected will be described. figure 2 It is a front view showing a partial cross section of the spark plug 1 . In addition, in figure 2 In the description, the direction of the axis CL1 of the spark plug 1 is defined as the vertical direction in the drawing, the lower side is defined as the front end side of the spark plug 1 , and the upper side is defined as the rear end side.

[0085] The spark plug 1 is composed of a cylindrical insulator 2 as an insulator, a cylindrical meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com