High-frequency welding impedor

A high-frequency welding and impedance device technology, applied in high-frequency current welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low production efficiency, affecting the yield of products, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

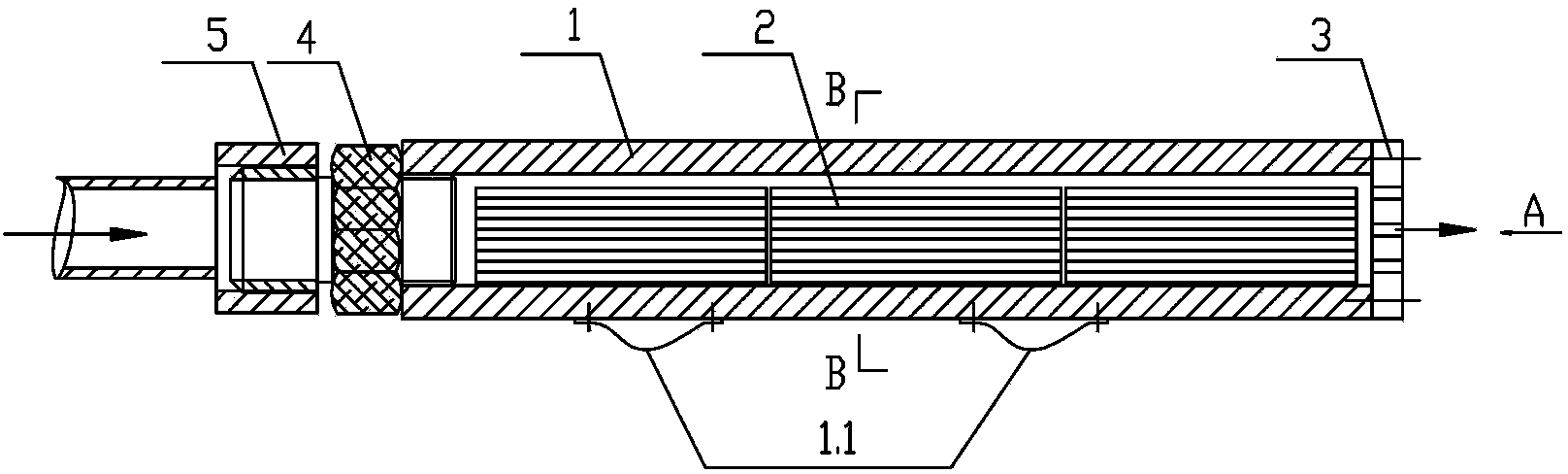

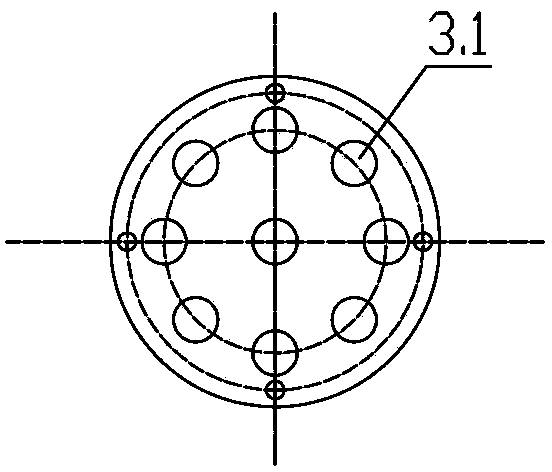

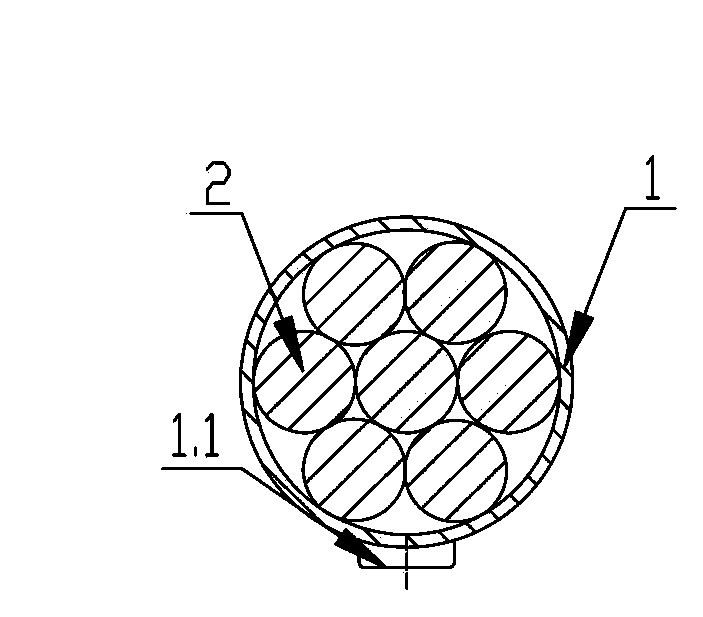

[0012] The high-frequency welding impedance shown in the figure has a cylindrical magnetic bar box 1, a magnetic bar 2 is installed in the cylindrical magnetic bar box 1, and one end of the cylindrical magnetic bar box 1 is connected with a stopper by bolts and nuts. Block 3, the other end of the cylindrical magnetic bar box 1 is threadedly connected with a quick-change joint 4, and the other end of the quick-change joint 4 is threaded with the quick-change water pipe 5. The magnetic bar box 1, the quick-change joint 4 and the inner cavity of the quick-change water pipe 5 are connected, and the end face of the stopper 3 is provided with nine stopper through holes 3.1. Two pads 1.1 are arranged at the bottom of the cylindrical magnetic bar box 1 .

[0013] When the present invention is used, the end of the quick-change water pipe 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com