Rotation quenching clamp

A technology of rotating quenching and clamp head, which is applied in the field of quenching clamps, and can solve the problems of high probability of waste parts of precision workpieces, different quenching temperatures of quenched workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

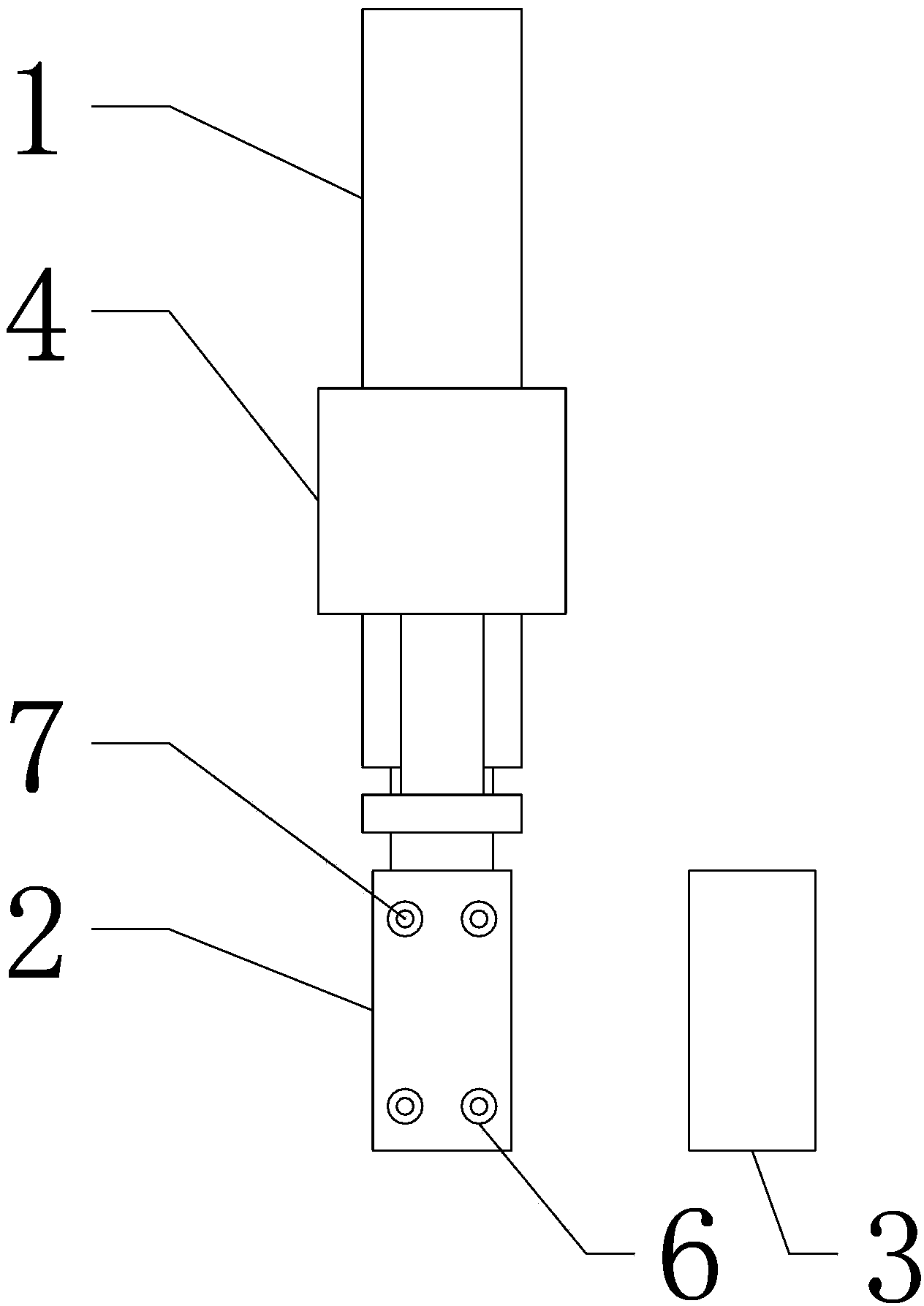

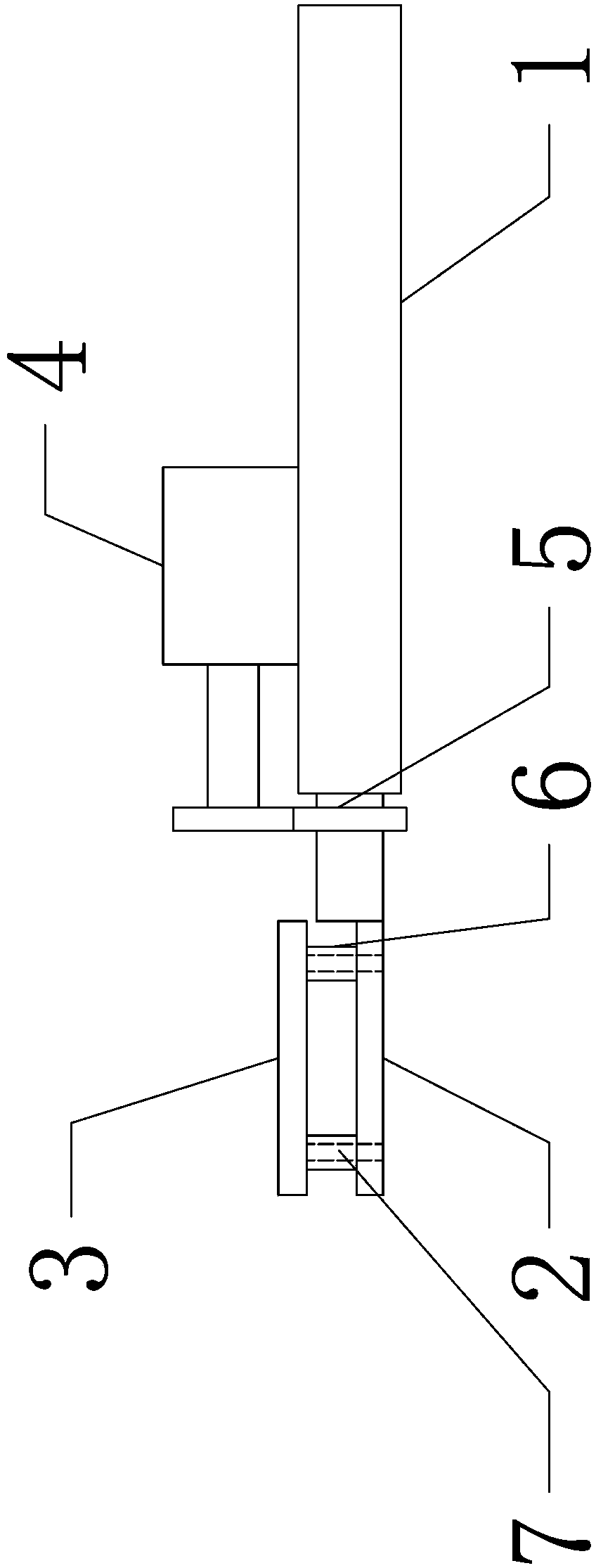

[0010] Such as figure 1 and figure 2 The rotary quenching pliers shown include: pliers arm 1, pliers head 2, auxiliary platen 3 and motor 4; Rotation; the rear end of the pliers head 2 is fixed with a drive gear 5, and the surface is provided with a magnet column 6; the motor 4 is fixed on the pliers arm 1, and the front output shaft gear sleeve is meshed with the drive gear 5 at the rear end of the pliers head 2; the auxiliary pressure plate 3 It has the same shape and size as the clamp head 2, and is adsorbed on the surface of the clamp head 2 by the magnet column 6; the clamp head 2 and the magnet column 6 are processed with a through hole 7 passing through the clamp head 2 and the magnet column 6;

[0011] The user of the present invention who has adopted the above-mentioned technical solution first absorbs the heated quenched workpiece through the magnet column 6. If the quenched workpiece is a flat plate structure, the auxiliary pressure plate 3 needs to be adsorbed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com