Rotary interception swing check valve

A rotary check valve technology, used in valve details, control valves, valve devices, etc., can solve problems such as non-adjustable valve disc opening, damage to pump stations or pipelines, and large water hammer when closing the valve. The effect of adjusting damping and solving water hammer problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

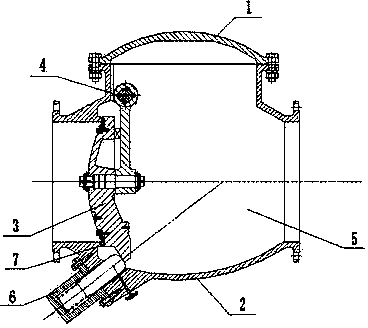

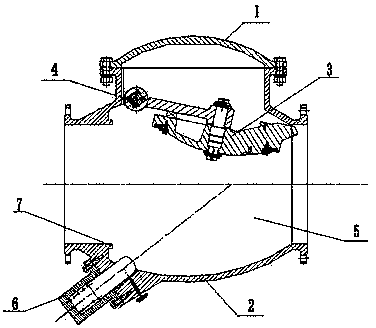

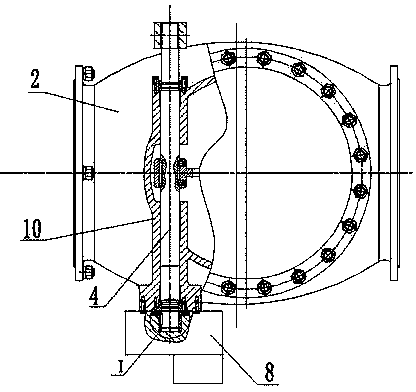

[0022] Such as figure 1 — Figure 6 As shown, the present invention includes a valve body 2, a valve cover 1 arranged on the valve body 2, a valve shaft 4 arranged at the upper end of the valve body 2 close to the water inlet end, and a valve disc 3 fixedly connected to the valve shaft 4. The water inlet end of the valve body 2 is provided with a valve seat 7 for sealing with the valve disc 3, and a drive sleeve 10 is sleeved on the valve shaft 4, and both ends of the valve shaft 4 protrude from the valve body 2, one end of which is connected to the valve body. The body 2 is sealed, and the transmission sleeve 10 on the other end is fixedly connected with the output end of the limit driving device 8 . The valve shaft 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com