Two-section pneumatic control system with any opening degree adjustable

A pneumatic control system, two-stage technology, applied in the direction of engine components, valve details, valve operation/release devices, etc., can solve the problems of complex control system, large energy consumption, large size, etc., to reduce production costs, Simple structure and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

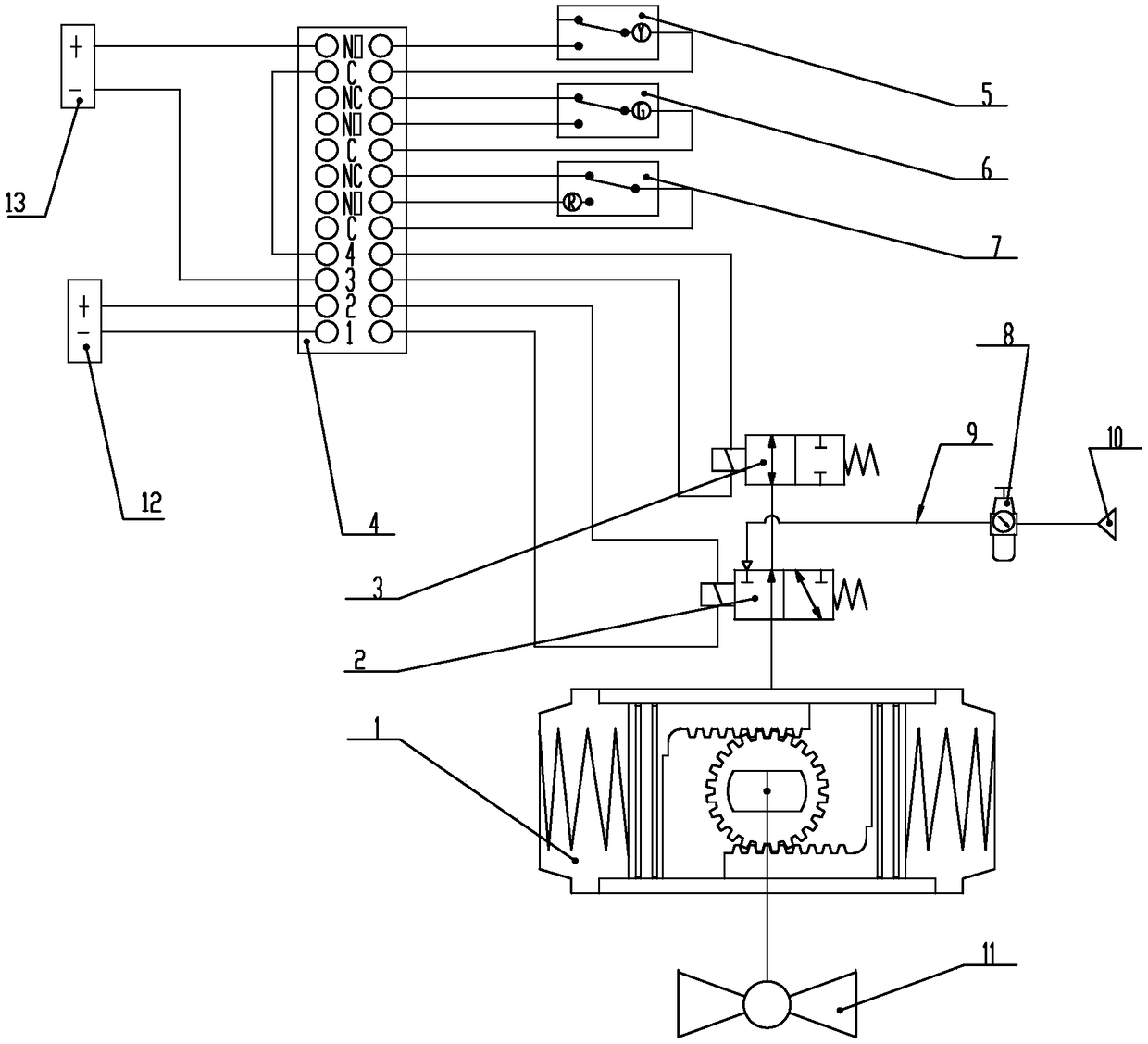

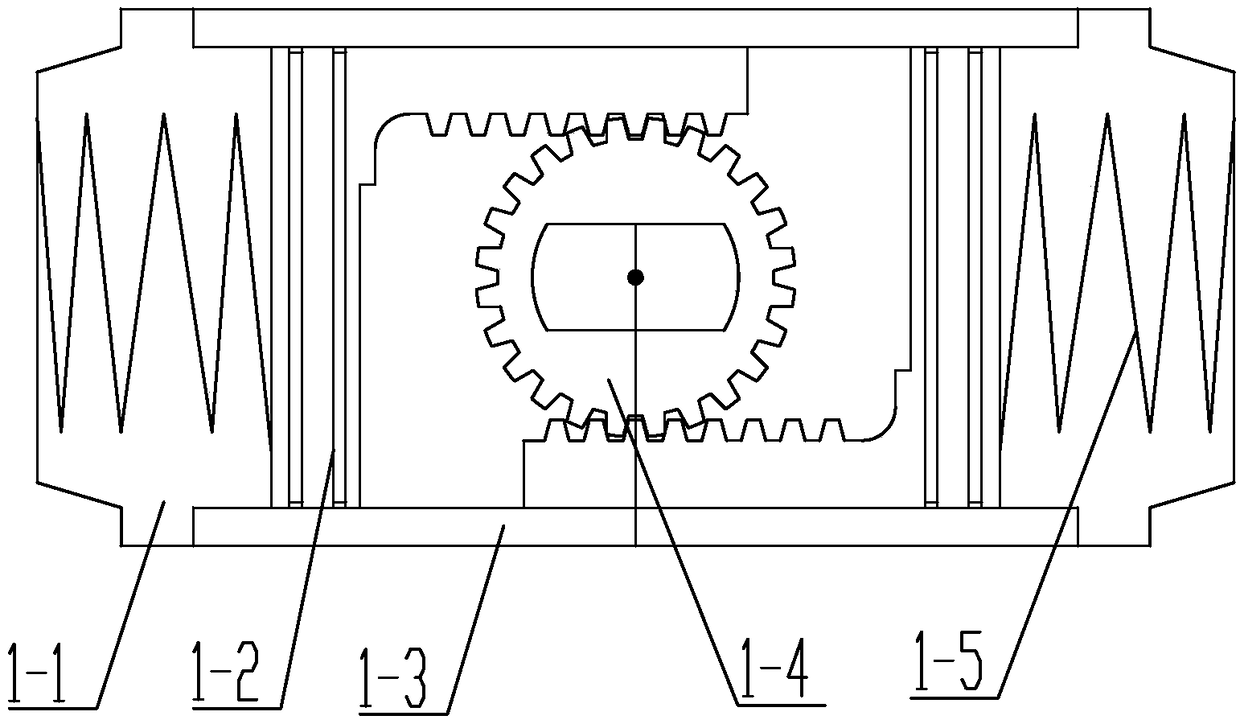

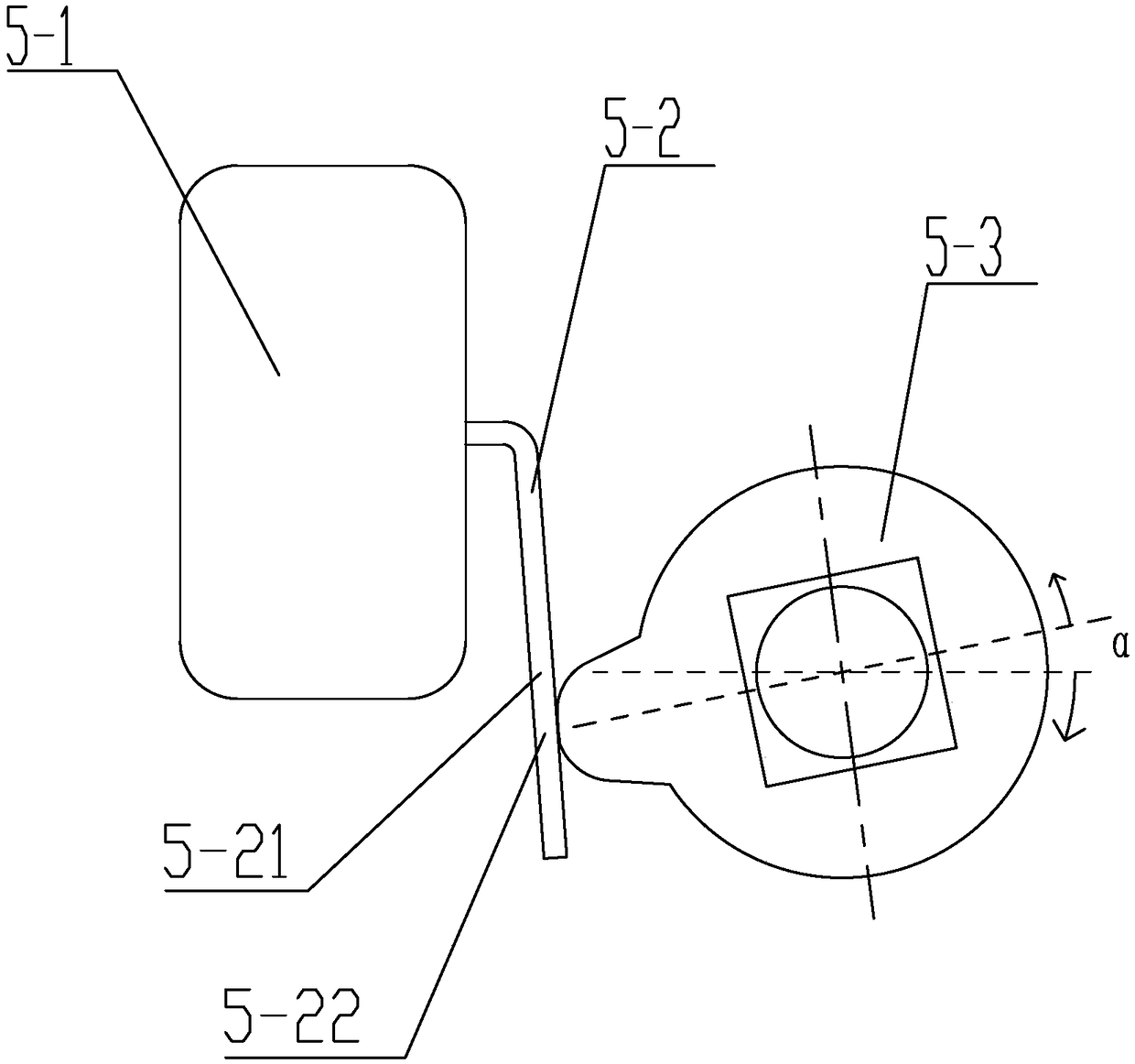

[0019] refer to figure 1 , figure 2 and image 3 , a two-stage pneumatic control system with adjustable opening, including a pneumatic actuator 1 and a valve 11, the pneumatic actuator 1 includes a cylinder head 1-1, a piston 1-2, a cylinder body 1-3 and an output shaft 1 -4, the cylinder head 1-1 is set on the cylinder body 1-3, the piston 1-2 is engaged with the output shaft 1-4 for transmission, and the driving piston 1-2 is arranged between the piston 1-2 and the cylinder head 1-1. The spring 1-5 that moves the center position of the cylinder body 1-3, the output shaft 1-4 is linked with the valve 11 and used to control the opening and closing of the valve 11, the pneumatic actuator 1 is an existing mature technology, and in this embodiment the pneumatic actuator The device 1 adopts a common type 90° angular stroke single cylinder spring return type p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com