Hydraulic damping device for truck suspension

A technology of hydraulic shock absorption and suspension, applied in the direction of suspension, shock absorber, elastic suspension, etc., can solve the problems such as the inability to buffer the impact force, the inability to drive the truck smoothly, and the inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

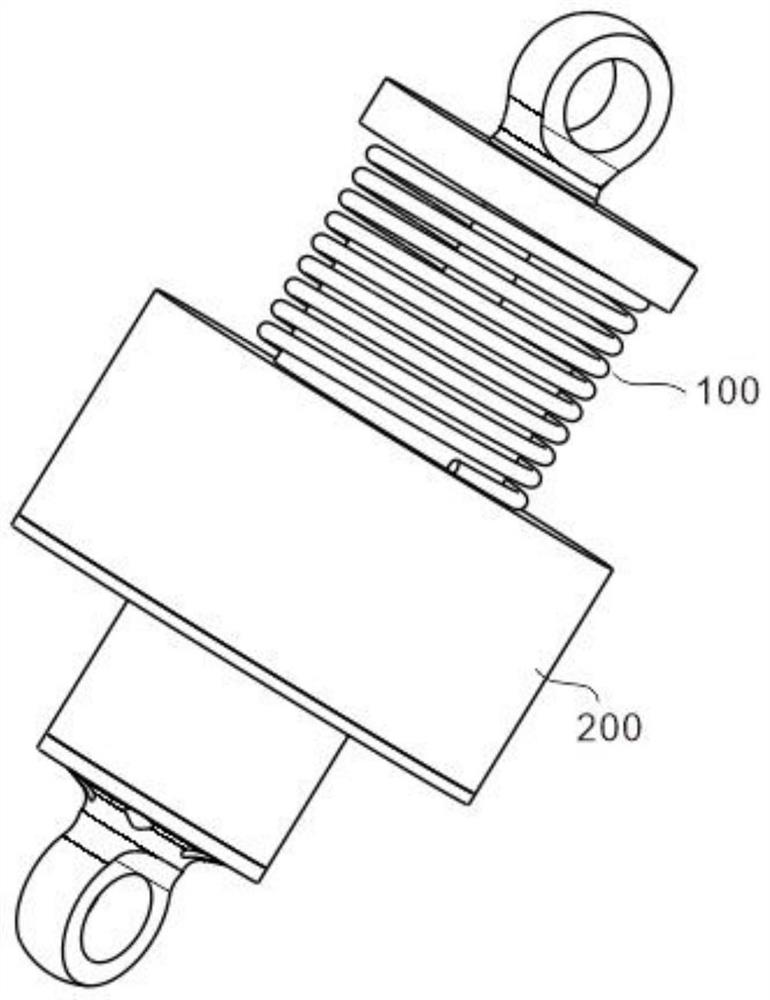

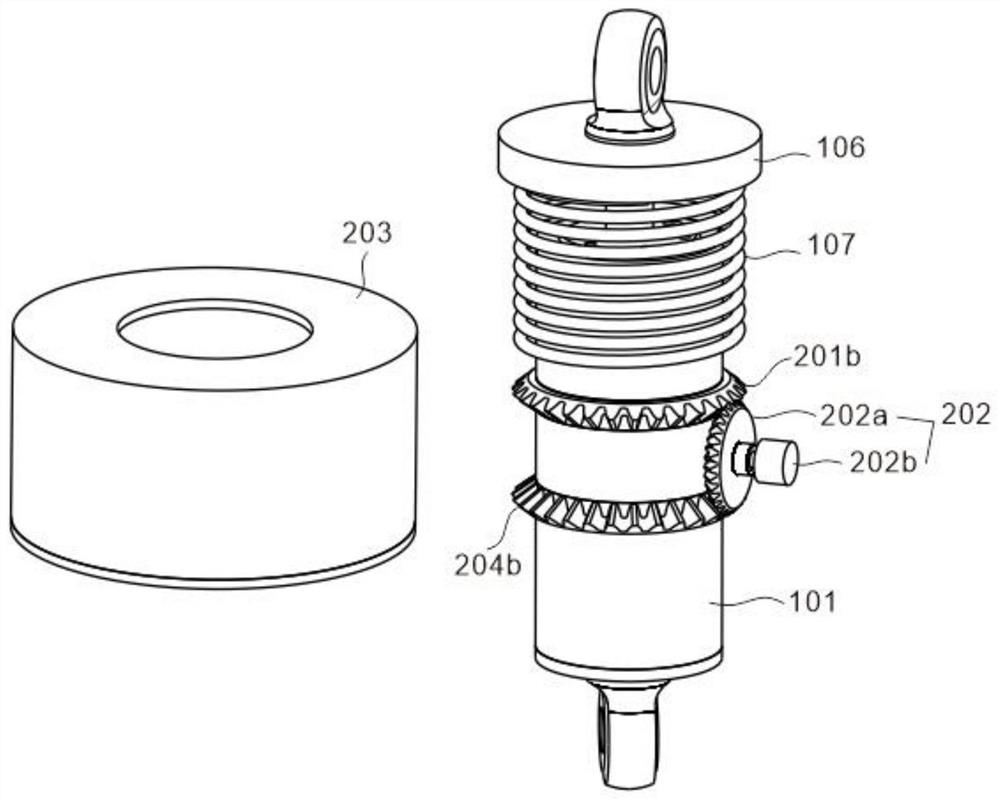

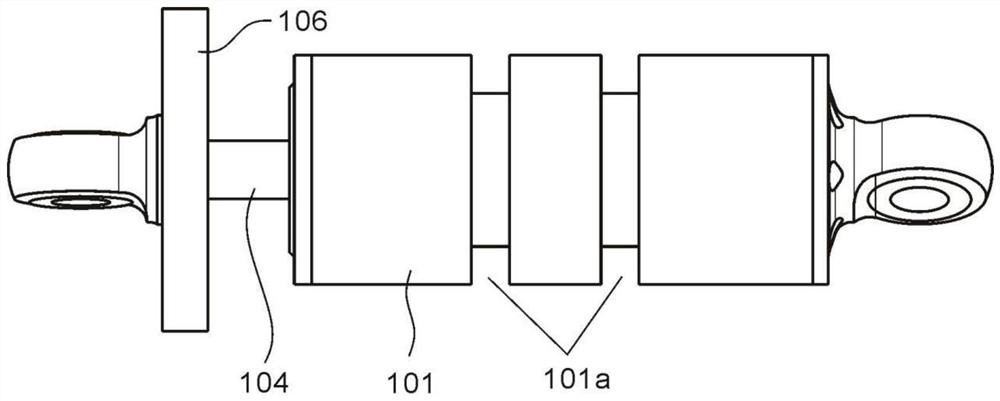

[0032] refer to Figure 1-9 , is the first embodiment of the present invention, which provides a hydraulic shock absorber for truck suspension. The hydraulic shock absorber for truck suspension includes a hydraulic shock absorber 100 and a damping adjustment member 200. The damping adjustment member 200 It is used to change the circulation path of the liquid in the hydraulic shock absorber 100, and the damping of the hydraulic shock absorber is changed through the size of the diameter of the flow path, so that the truck can adapt to different road conditions.

[0033] Specifically, the hydraulic shock absorber 100 includes a damper cavity 101, a piston 102, a connecting rod 104, a baffle 106 and a spring 107, the connecting rod 104 connects the piston 102 and the baffle 106, and the piston 102 is arranged in the damper cavity 101 , Two first ring grooves 101a are arranged on the side of the damper cavity 101 .

[0034] The damping adjustment member 200 includes a first adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com