Exhaust pressure adjusting device

A technology of regulating device and exhaust pressure, applied in the direction of machine/engine, mechanical equipment, engine control, etc., can solve the problems of high motor temperature damage, short transmission distance, small internal space, etc., to achieve reliable work, easy connection, extension The effect of transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

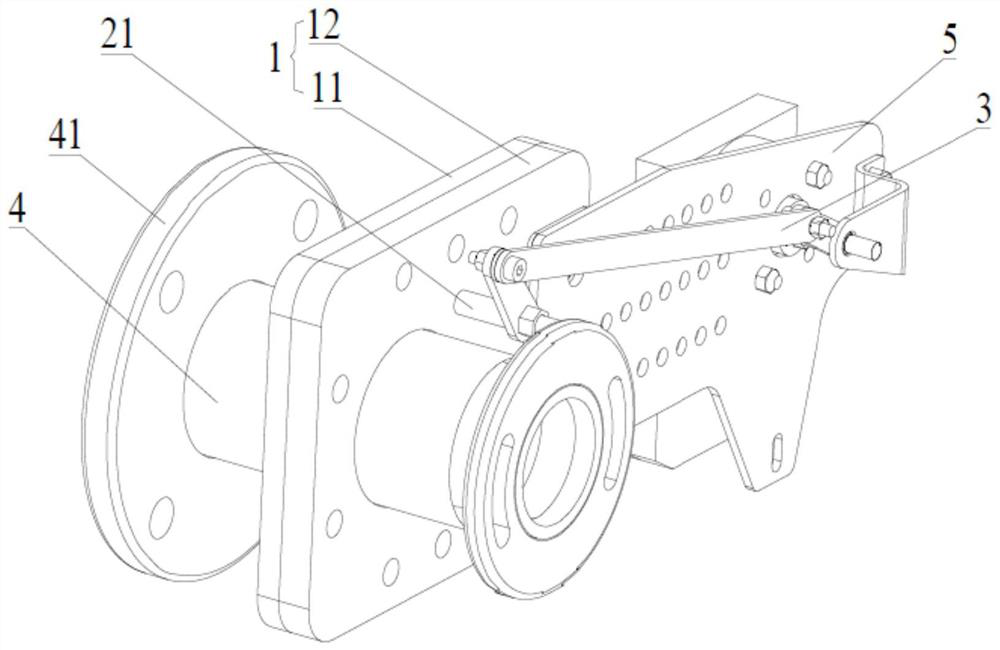

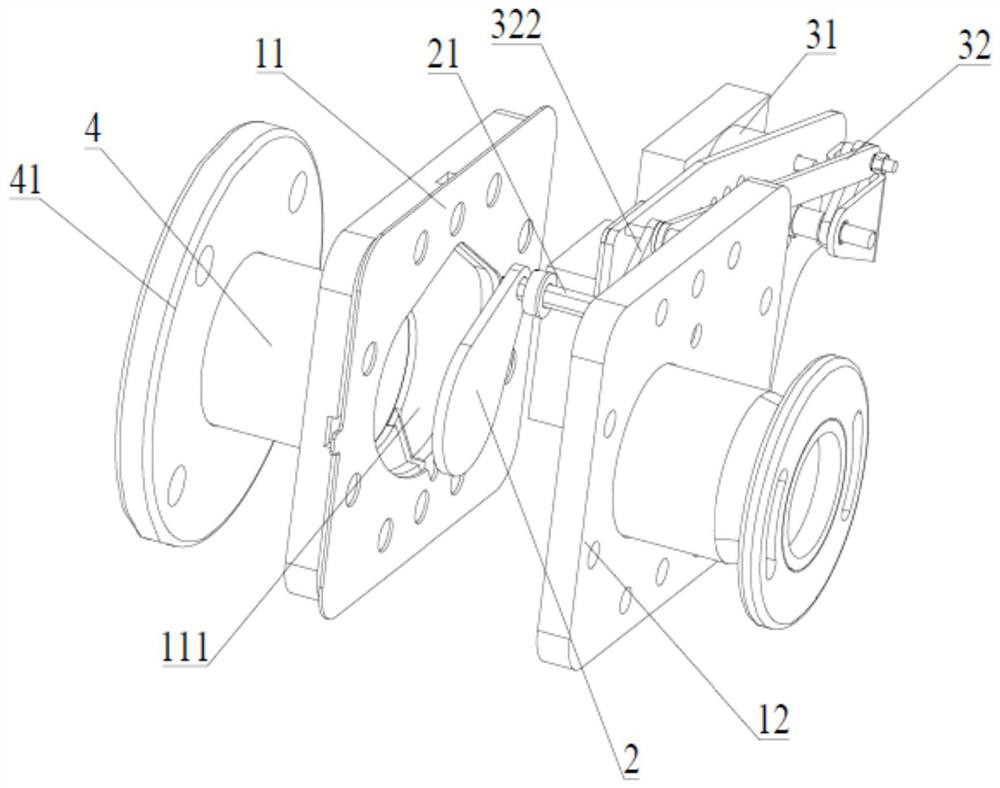

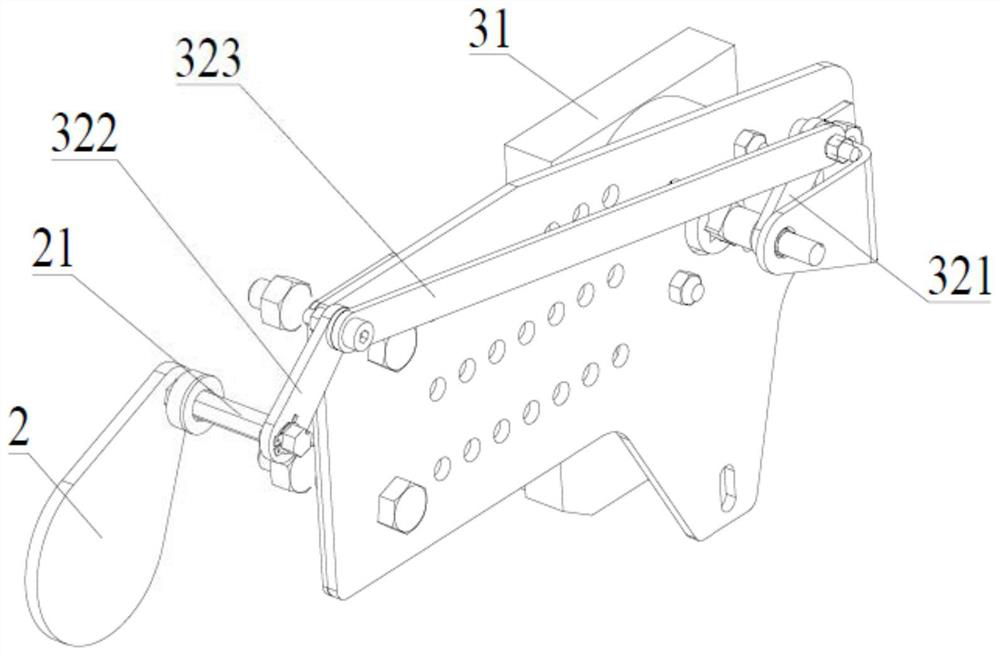

[0034] Such as Figure 1 to Figure 9 Shown is a first embodiment of an exhaust pressure regulating device, including a valve body 1, a valve plate 2 arranged inside the valve body 1, and a drive mechanism 3 connected to the valve plate 2; the valve The body 1 includes a detachably connected first valve body 11 and a second valve body 12, the first valve body 11 and the second valve body 12 communicate with each other and are provided with a smoke exhaust pipe 4; the first valve body 11 One end close to the second valve body 12 is also provided with a cavity 111 communicating with the smoke exhaust pipe 4, the valve plate 2 is movably arranged in the cavity 111, and the valve plate 2 is fixedly provided with A rotating shaft 21 , the rotating shaft 21 passes through the second valve body 12 and is in transmission connection with the driving mechanism 3 , and the valve plate 2 is driven by the driving mechanism 3 to rotate around the rotating shaft 21 .

[0035] It should be un...

Embodiment 2

[0046] Such as Figure 10 Shown is a second embodiment of an exhaust pressure regulating device. The difference between this embodiment and Embodiment 1 is that this embodiment also includes a fixing bracket 6, which is detachably connected to the first valve body 11. , the device is fixed by the fixing bracket 6, so as to avoid the vibration of the device caused by the rotation of the motor during the working process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com