Refrigerator drawer and refrigerator applying same

A drawer and refrigerator technology, applied in applications, household appliances, household refrigeration devices, etc., can solve the problem of inconvenience in taking things, achieve smooth and labor-saving automatic flipping, good product experience, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

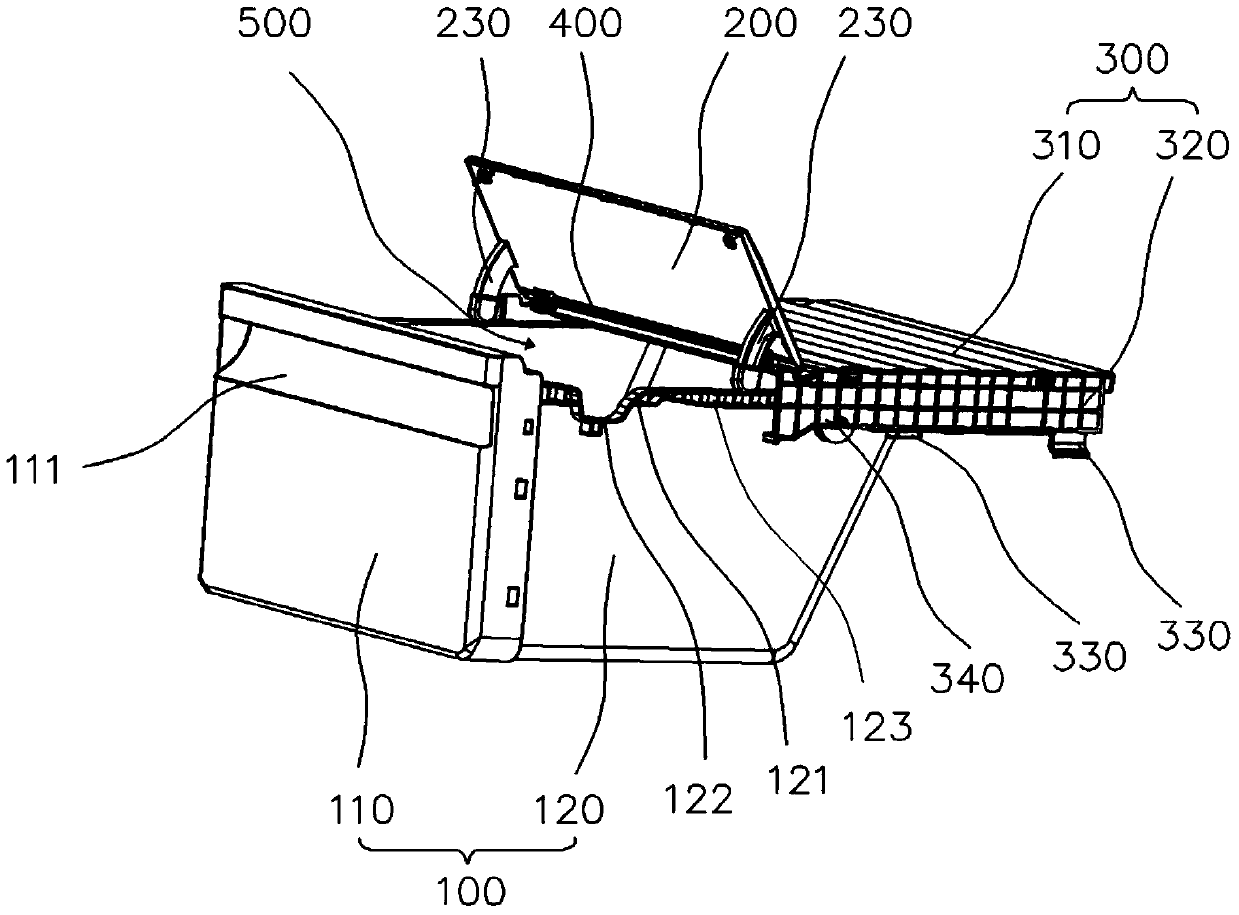

[0036] Such as figure 1 As shown, the cover plate 200 is in the shape of a cuboid, and a rotating shaft 400 is arranged laterally on the rear side of the cover plate 200 . The rotating shaft 400 can rotate freely with its axis center, the two ends of the rotating shaft 400 are movably connected with the inner tank walls on both sides, the cover plate 200 is fixedly connected with the rotating shaft 400, and the rotating shaft 400 freely rotates to drive the fixed cover plate 200 to turn over to reach the cover plate 200 The purpose of opening or closing. The rotating shaft 400 can also be in the form of a fixed rod that does not rotate itself. The two ends of the rotating shaft 400 are fixedly connected to the inner wall of the two sides. The cover plate 200 is flexibly connected to the rotating shaft 400. The purpose of opening or closing. In order to make the cover plate 200 turn over more easily, the former connection structure is preferred in this embodiment.

[0037] T...

Embodiment 2

[0046] The front and rear lengths of the cover plate 200 can be increased or decreased as appropriate, and its rear portion is fixed on the inner wall of the inner container using a shelf (not shown) to cover the uncovered drawer opening behind the cover plate 200 .

[0047] This embodiment provides a better solution, such as figure 1 As shown, a layer frame 300 is added. The layer frame 300 is composed of a flat plate 310 and side plates 320 on both sides. It is an integrated structure. The side plates 320 are fixed on the inner tank ribs (not shown) on the inner tank wall by buckles 330 , the shelf 300 is easy to install and does not need to be fixed by other fixing parts, and a chute (not shown) for sliding the drawer 100 is provided on the shelf 300 , and the drawer 100 is slidably connected with the shelf 300 . A chute (not shown) of the drawer 100 is provided on the side plate 320, and a runner 340 is provided on the side plate 320. The flange 123 of the drawer body 120 ...

Embodiment 3

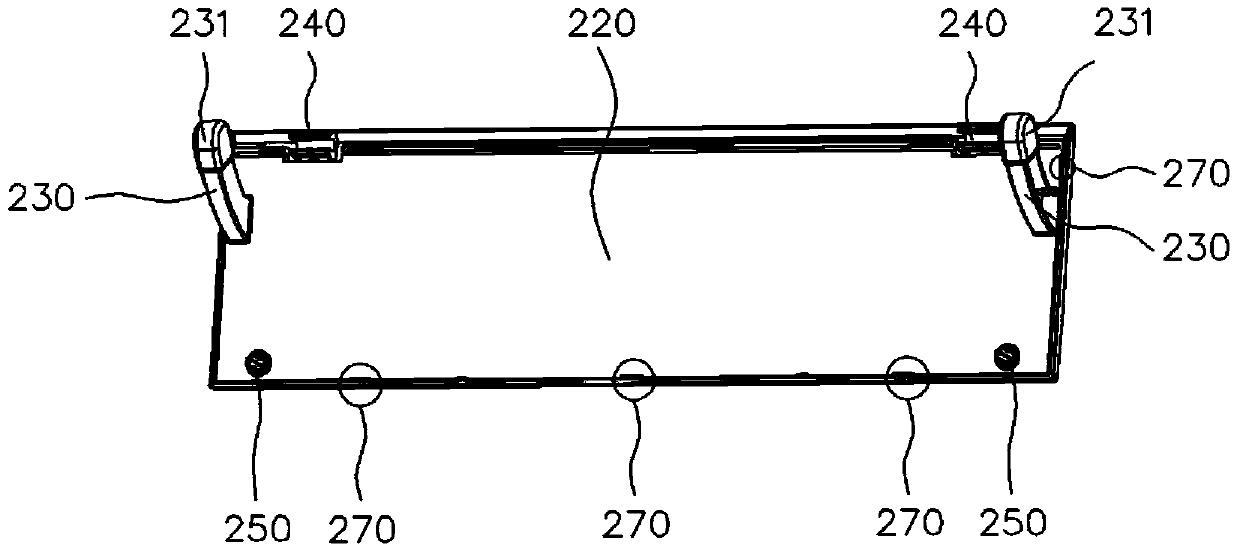

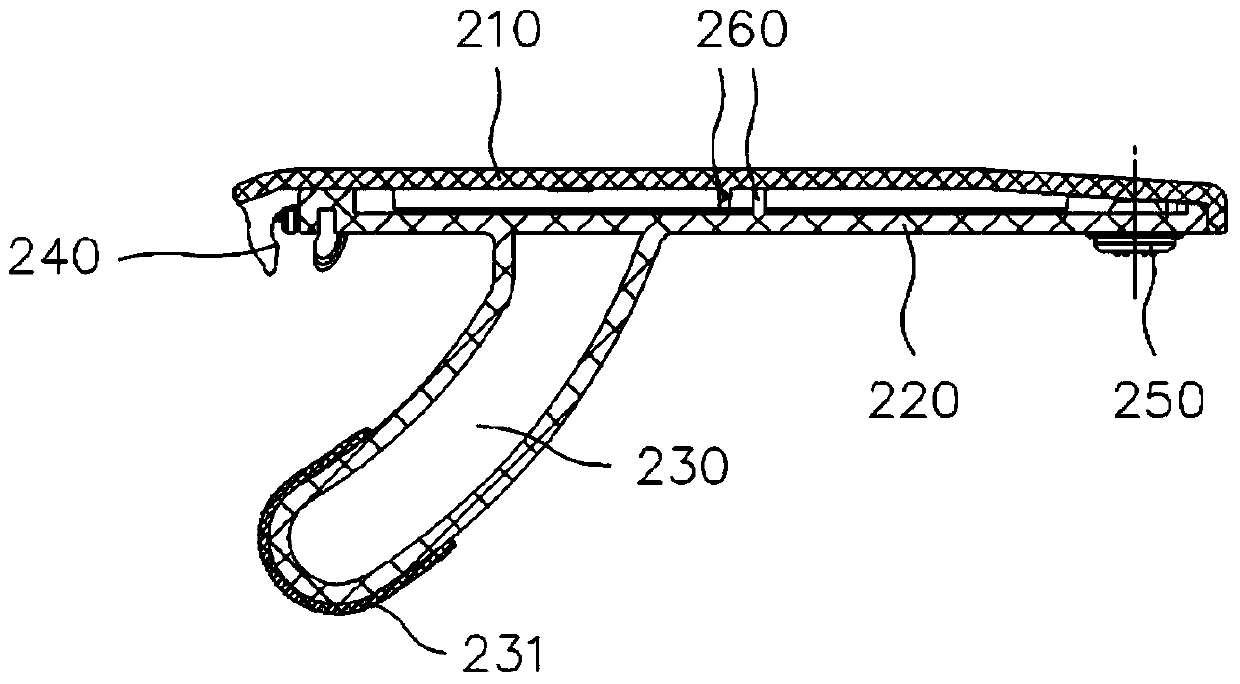

[0053] Such as figure 2 with image 3 As shown, the cover plate 200 can be a whole plate, but in order to reduce weight and provide users with better use effect, in this embodiment, the cover plate 200 is composed of an outer cover plate 210 and an inner cover plate 220, the outer cover plate 210 and the inner cover 220 are locked and fixed by the hook 270, and after the two are fixed, a gap is formed in the middle. Because the middle part of the cover plate 200 is hollow, the weight is reduced. When the drawer 100 is pushed and pulled, the friction caused by the gravity of the raised structure 230 is reduced, the cover plate 200 can be rotated more easily, and the sliding noise is effectively reduced.

[0054] Reinforcing ribs 260 are provided on the outer cover 210 and the inner cover 220 respectively. After the two are fixed to form a gap, the reinforcing ribs 260 can provide support to prevent shrinkage and deformation of the flanging while ensuring the strength of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com