A new type of health-care activated carbon fiber honeycomb quilt manufacturing method

A technology of activated carbon fibers and production methods, which is applied in the production of furniture covers, household utensils, applications, etc., can solve the problems of slow adsorption speed, limited application range, and low separation efficiency, and achieve high moisture conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] A method for making a novel health-care active carbon fiber honeycomb quilt, comprising the following specific steps:

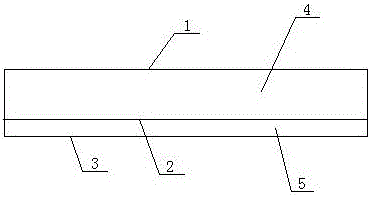

[0020] (1) After stacking the first one-way moisture-permeable fabric layer 1, the second one-way moisture-permeable fabric layer 2 and the third one-way moisture-permeable fabric layer 3 in sequence, quilting is performed on three sides;

[0021] (2) To the interlayer between the first one-way moisture-permeable cloth layer 1 and the second one-way moisture-permeable cloth layer 2: fill the first filling layer 4 with thermal insulation cotton;

[0022] (3) To the interlayer between the second unidirectional moisture-permeable cloth layer 2 and the third unidirectional moisture-permeable cloth layer 3: the second filling layer 5 is filled with activated carbon fiber cotton;

[0023] (4) Seal the quilt cover filled with thermal insulation cotton and activated carbon fiber cotton, and then carry out hemming molding.

[0024] Wherein, the moisture-permea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com