Roof structure with vertical lockrand

A technology of vertical seaming and seaming, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of high construction difficulty and inability to achieve roof waterproofing well, and achieve simple construction and low cost. low, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

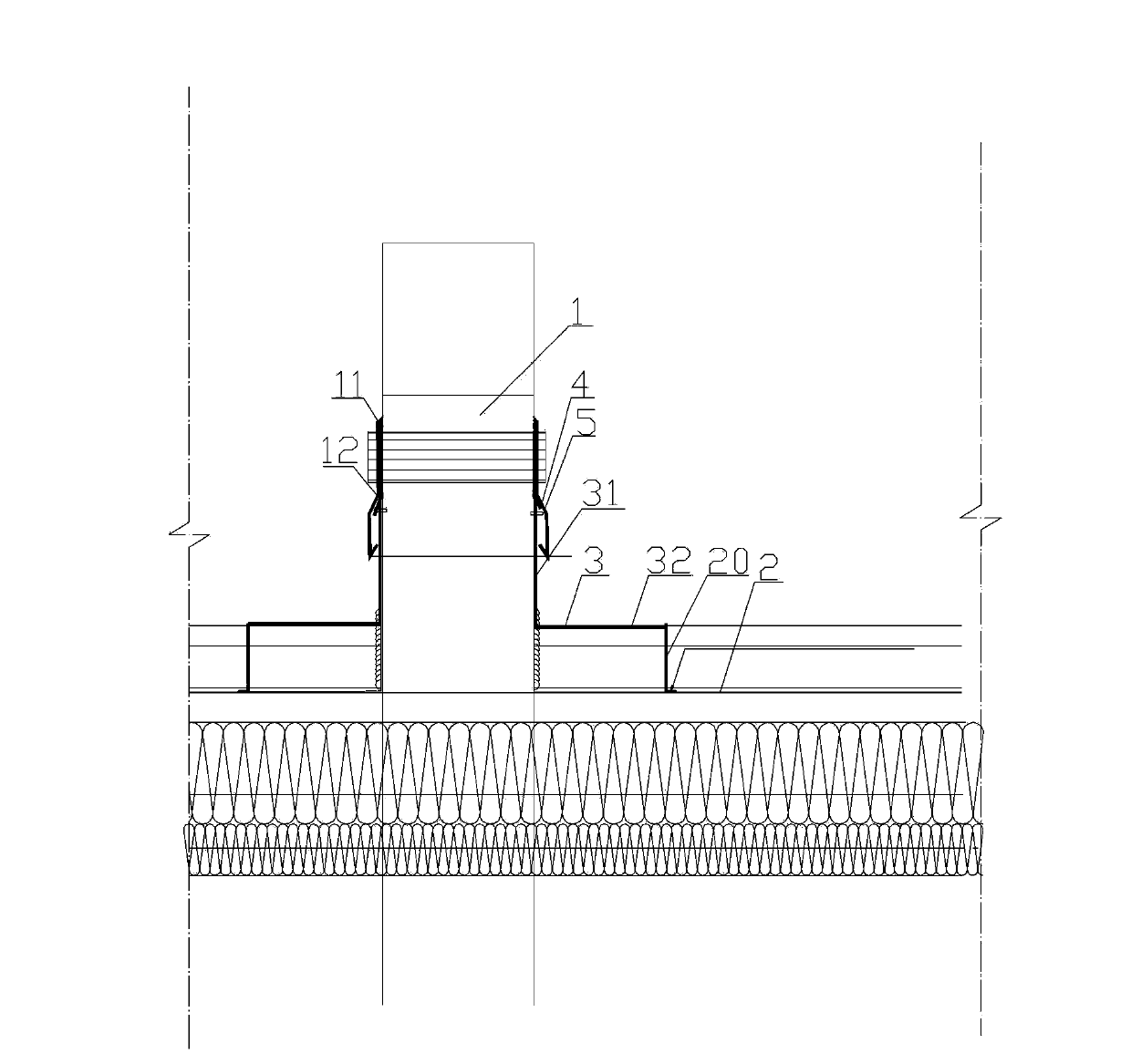

[0020] Such as figure 1 As shown in the figure, a vertical seam roof structure, which includes a vertical structural member 1 and a seam roof panel 2. The seam roof panel 2 is laid on the top of the roof, and the vertical structural member 1 passes under the seam roof panel 2. And extend to a certain height outside the seam roof panel 2.

[0021] Further, it also includes a plurality of folding structure 3, the plurality of folding structure 3 are respectively arranged along the vertical direction of the vertical structure 1, wherein the upper side of the folding structure 3 is fixed to the vertical structure 1 On the upper side, the lower side of the folding structure 3 is fixedly installed above the seam roof panel 2; a waterproof member 4 is also included, which covers the connection position of the folding ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap