Shunting type elongated mortar stirrer

A lengthened and split-flow technology, which is applied to cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve problems such as short mixing length, unstable mortar quality, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

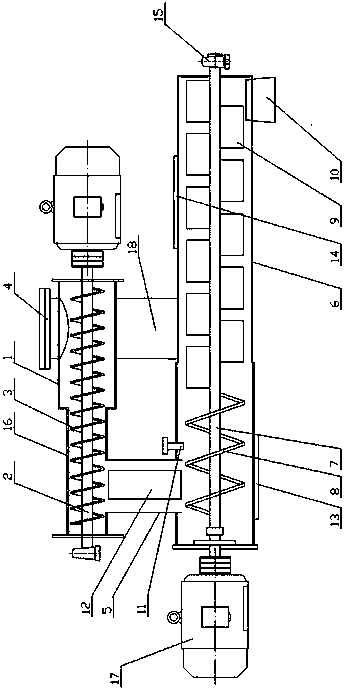

[0018] Embodiment: the split-flow extended type mortar mixer of this example, as figure 1 , including a conveying cylinder 1, an extrusion chamber 16 is arranged inside the rear section of the conveying cylinder, and the inner diameter of the extrusion chamber is smaller than the inner diameter of the conveying cylinder. There is a conveying screw shaft 2 inside the conveying cylinder, and a conveying blade 3 arranged in a spiral is arranged on the conveying screw shaft, and a feeding port 4 is opened on the conveying cylinder, and the end of the conveying cylinder is connected with a mixing cylinder through a feeding port 5 6. There is a first observation and cleaning window 12 on the feeding port. A water inlet 11 is provided at the joint between the feeding port and the mixing cylinder. The inside of the mixing cylinder is provided with a rotating shaft 7, and one end of the mixing cylinder is provided with a bearing 15, and the rotating shaft is connected in the bearing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com