Feedback current sampling device for shunt erosion switch power

A technology of switching power supply and feedback current, which is applied in the direction of electrolytic capacitors, output power conversion devices, circuits, etc., can solve the problems of sampling devices such as large power and shape, large heat dissipation, and large price and volume, and achieve reasonable structure and low cost. The effect of small structure volume and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

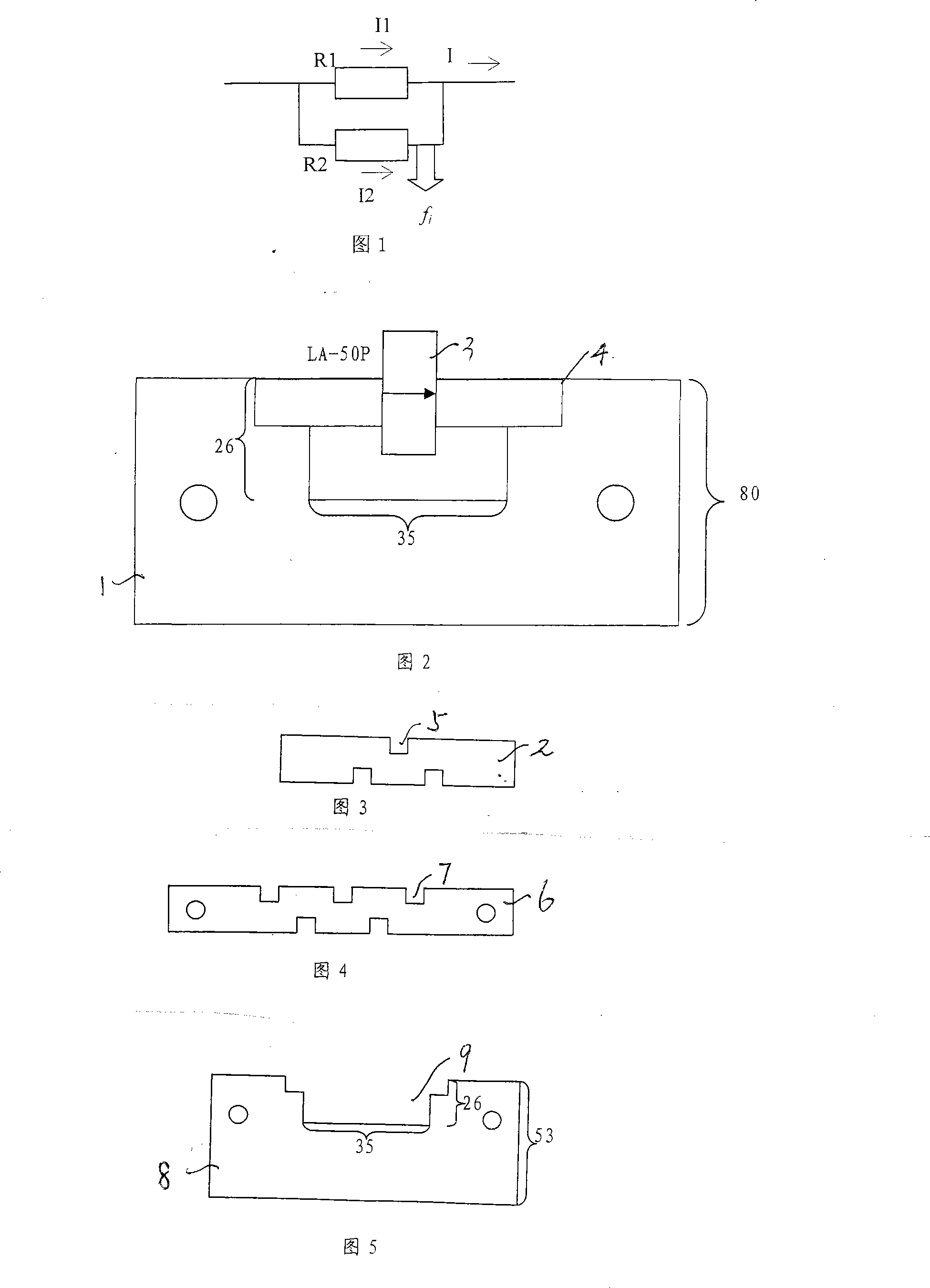

[0017] Choose to implement the present invention on the corrosion power supply (NHDI-1210), the rated output of this power supply is 12V 1000A, the LA50P Hall sensor with high cost performance, small size, only 17 grams in weight and only 30 to 40 yuan is selected as the sampling device to replace manganese Copper shunt, its rated measuring current is 50A, and the ratio of the output current of the corrosion power supply is 1:20. thus corresponding to R in Figure 1 1 with R 2 The ratio should also be around 1:20. In order to make the R in the above formula as far as possible 1 / R 1 +R 2 as a constant, the R 1 with R 2 The production materials of the same batch are made of the same material, and the two work under the same working conditions as much as possible to ensure the feedback signal f i It can accurately reflect the change of the output current I of the corrosion power supply. Open a 35mm×26mm slot on the original output row of the corrosion power supply (sectio...

Embodiment 2

[0019] The extended test is carried out on the corrosion power supply (NHDI-2005), the rated output of which is 5V 2000A, and the ratio of the rated measuring current of LA50P to the rated current of the corrosion power supply is 1:40. Since the components are common and interchangeable as much as possible, the structure of the shunt row is still used in Figure 2, the slotting method is still 35mm×26mm, and the effective cross-sectional area of the shunt row is 20×54=1080mm 2 , and then take the same batch of material as the shunt row and make it according to Figure 4 with a cross-section of 27mm 2 The sampling row 6 is connected with the LA50P Hall sensor in series, embedded in the groove of the shunt row, and then the sampling row and the shunt row are welded to form a good contact. Coefficient correction notches 7 are arranged on the sampling row 6 .

Embodiment 3

[0021] The present invention is applied to a corrosion power supply (NHD-I0505) with a rated output of 6V 500A. Because the rated current of the power supply is reduced, the height of the shunt bar 8 is reduced from 80 mm to 53 mm, and the slot size remains unchanged. In this way, the shunt bar forms a The section is 20mm×27mm=540mm 2 , calculated according to the ratio of the rated measurement current of the LA50P Hall sensor to the rated current of the corrosion power supply is 1:10, the sampling section is 54mm 2 Left and right, so it is appropriate to borrow the parts in Figure 3. Connect the LA50P Hall sensor on the sampling row in Figure 3, embed it in the groove 9 of the shunt row, and then weld the sampling row and the shunt row to form a good contact. Welding or crimping causes the current of the sampling row to be too large or too small, which can be adjusted by changing the length and width of the slot in the sampling row. The groove is divided into the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com