The sealing tooth structure to prevent the generator bearing from throwing oil and oil mist from overflowing

A technology for generator bearings and sealing teeth, which is applied to engine sealing, hydroelectric power generation, engine components, etc., can solve the problems of easy aging of elastic seals and reduced service life, etc., and achieve good air sealing effect, good effect, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

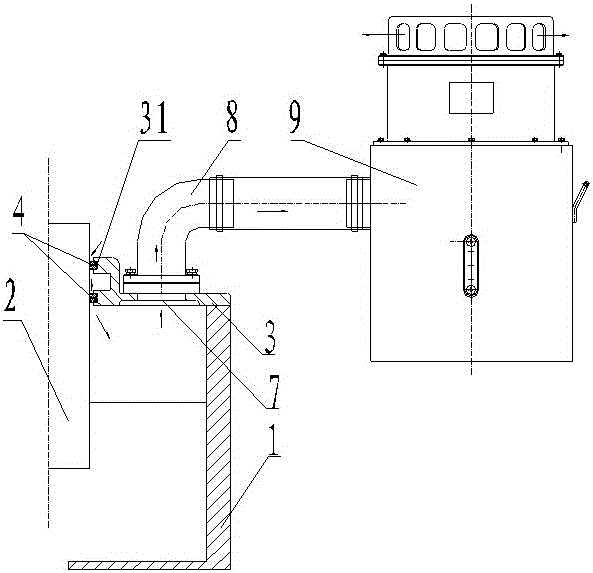

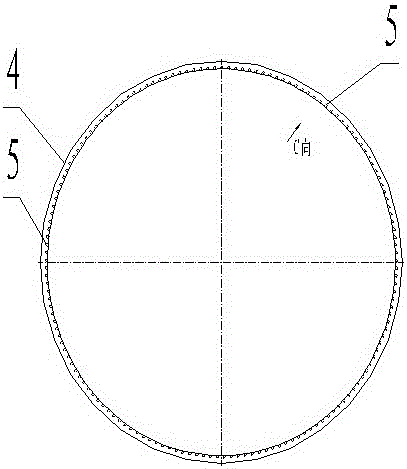

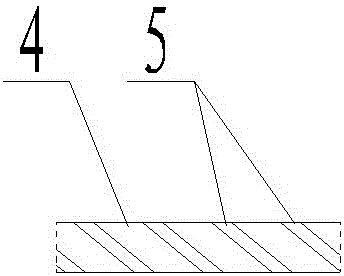

[0027] Such as figure 1 , 2 , 5, and 6, the sealing tooth structure for preventing the oil mist overflow of the generator bearing of the present invention includes an oil tank 1 and a rotating shaft 2 arranged on the generator body, and the cavity inside the oil tank 1 is used as a storage for the rotating parts of the generator (Bearing) The lubricating oil for lubrication is a surrounding groove. As the temperature rises, the high-speed rotation of the bearing soaked in the lubricating oil will agitate and impact the oil, causing the lubricating oil to produce oil mist, and even make the Lubricating oil splashes and fills the cavity inside the oil tank 1; in the improvement of the present invention, a sealing cover 3 is provided between the oil tank 1 and the rotating shaft 2 to seal the space between the oil tank 1 and the rotating shaft 2 to form a relatively closed airtight The cavity basically isolates the cavity inside the entire oil tank 1 from the outside world; sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com