An electric energy meter calibration table

A technology of electric energy meter and meter calibration table, which is applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve the problems of inefficiency of repeated operation of equipment, and achieve the effect of saving equipment, high efficiency and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

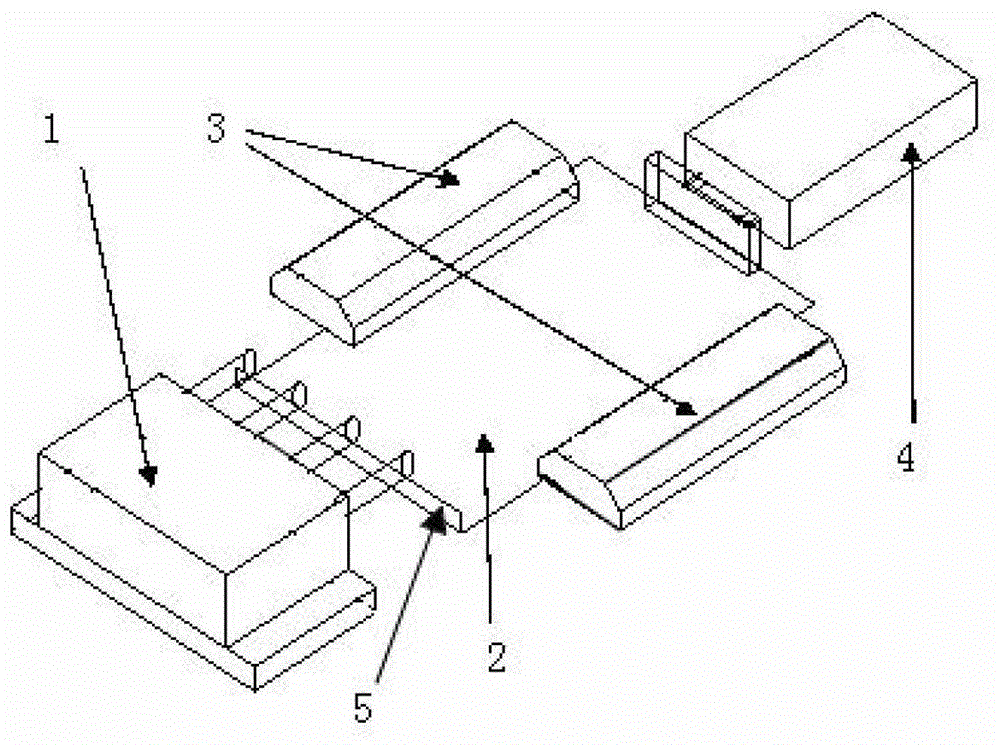

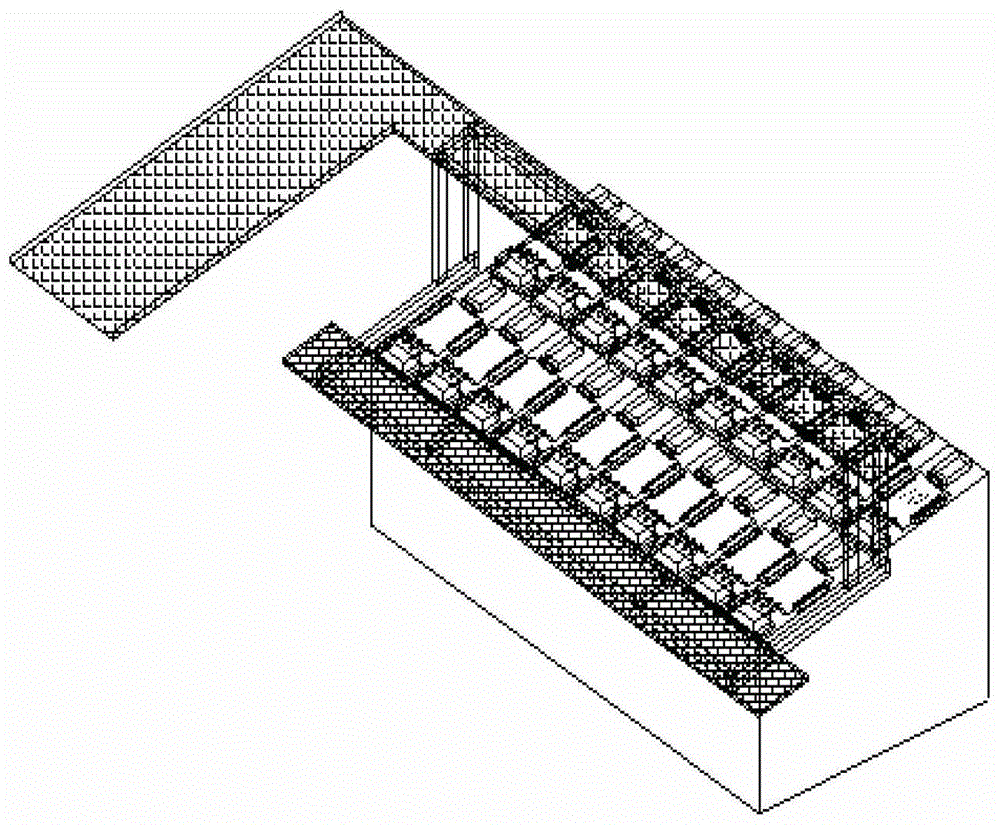

[0020] A meter calibration table for an electric energy meter, comprising a worktable, at least one detection unit is arranged on the worktable, the detection unit includes a cylinder 4, the push rod of the cylinder 4 is connected with a push block, the The push block is fixedly connected with the support plate 2 for placing the electric energy meter, and the corresponding position of the support plate 2 is provided with a detection terminal 1. When the push rod of the cylinder 4 is pushed out, the push rod pushes the electric energy meter through the push block, so that the electric energy meter Effective contact with detection terminal 1.

[0021] Further improvements of the present invention include:

[0022] The detection units on the working table are distributed in two rows up and down, and each row has 10 groups of detection units.

[0023] The end of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com