Transformer lead connection structure

A lead connection, transformer technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of prolonging working time, increasing labor intensity, and small connection area, reducing working time, improving working efficiency, and improving electrical conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

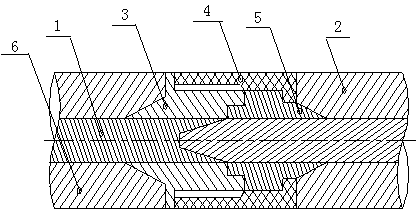

[0015] Accompanying drawing is the specific embodiment of the present invention.

[0016] like figure 1 The transformer lead wire connection structure of the present invention shown includes a crepe paper insulation layer 6, copper rod A1 and copper rod B2, the copper rod A1 is connected to the copper rod B2 in a tapered shape, and the copper rod A1 and the copper rod B2 are surrounded by formed insulating threaded columns 3. The self-insulating layer formed by the formed insulating threaded sleeve 4 and the formed insulating sleeve 5 .

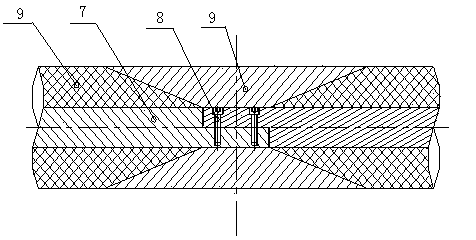

[0017] like figure 2 The traditional lead connection structure shown includes copper rod C7, bolt 8 and insulating layer 9. The copper rod A1 and copper rod B2 of the present invention are conically connected, replacing the traditional copper rod and bolt 8 crimping method, increasing the copper rod The effective connection area is improved, and the electrical conductivity is improved. Among them, the formed insulating thread column 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com