Low row steam generator inspection probe

A technology of detectors and inspection groups, applied to the primary side of steam generators, steam generation, steam boilers, etc., can solve problems such as impossible inspection, traveling of tubular parts, and device jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Illustrative embodiments incorporating one or more aspects of the present invention are described and illustrated in the drawings. These illustrated examples are not intended to be a general limitation of the invention. For example, one or more aspects of the invention can be used in other embodiments and even other types of devices. Furthermore, certain terms are used herein for convenience only and are not to be construed as limitations of the present invention. Also, in the drawings, the same reference numerals are used to designate the same elements.

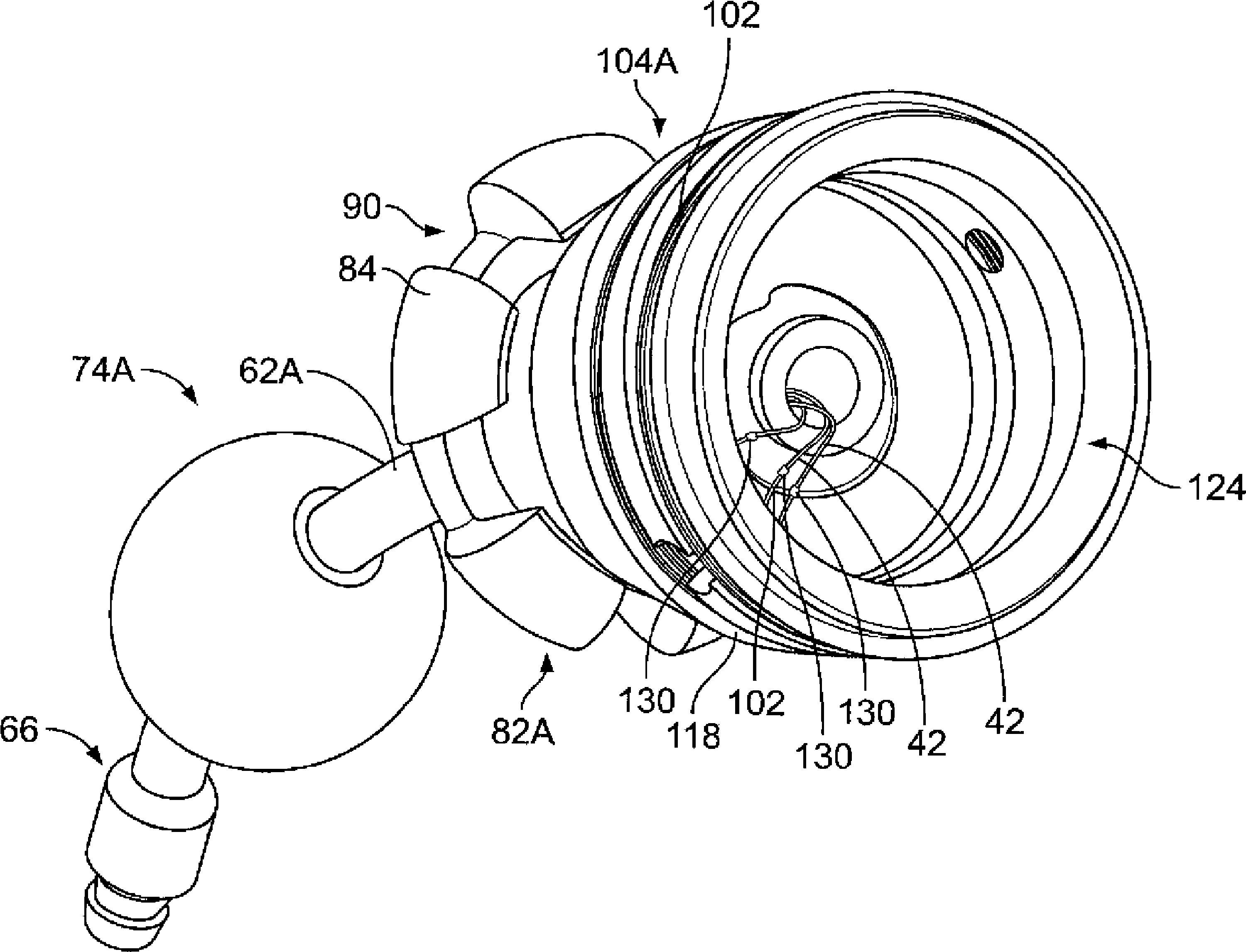

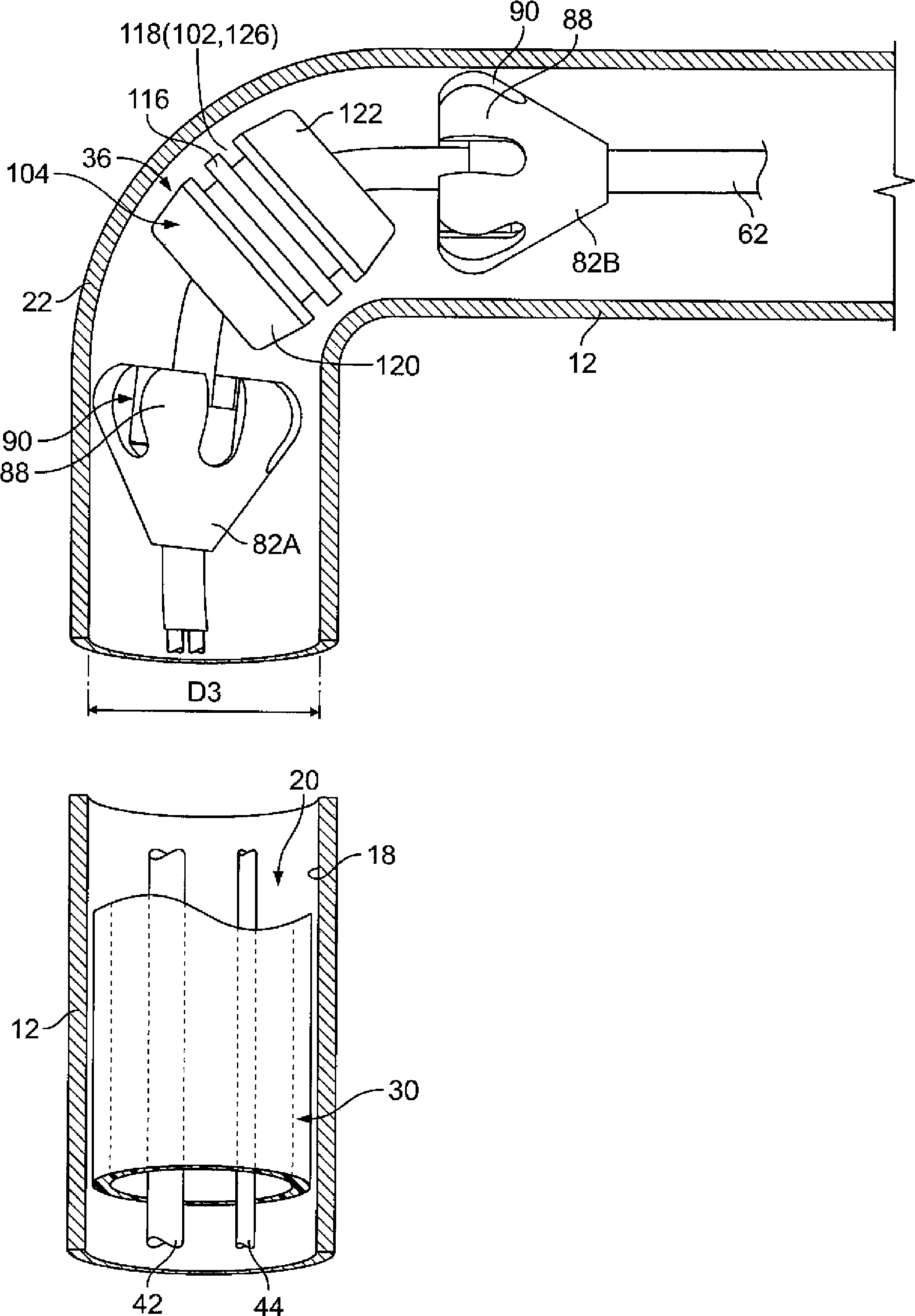

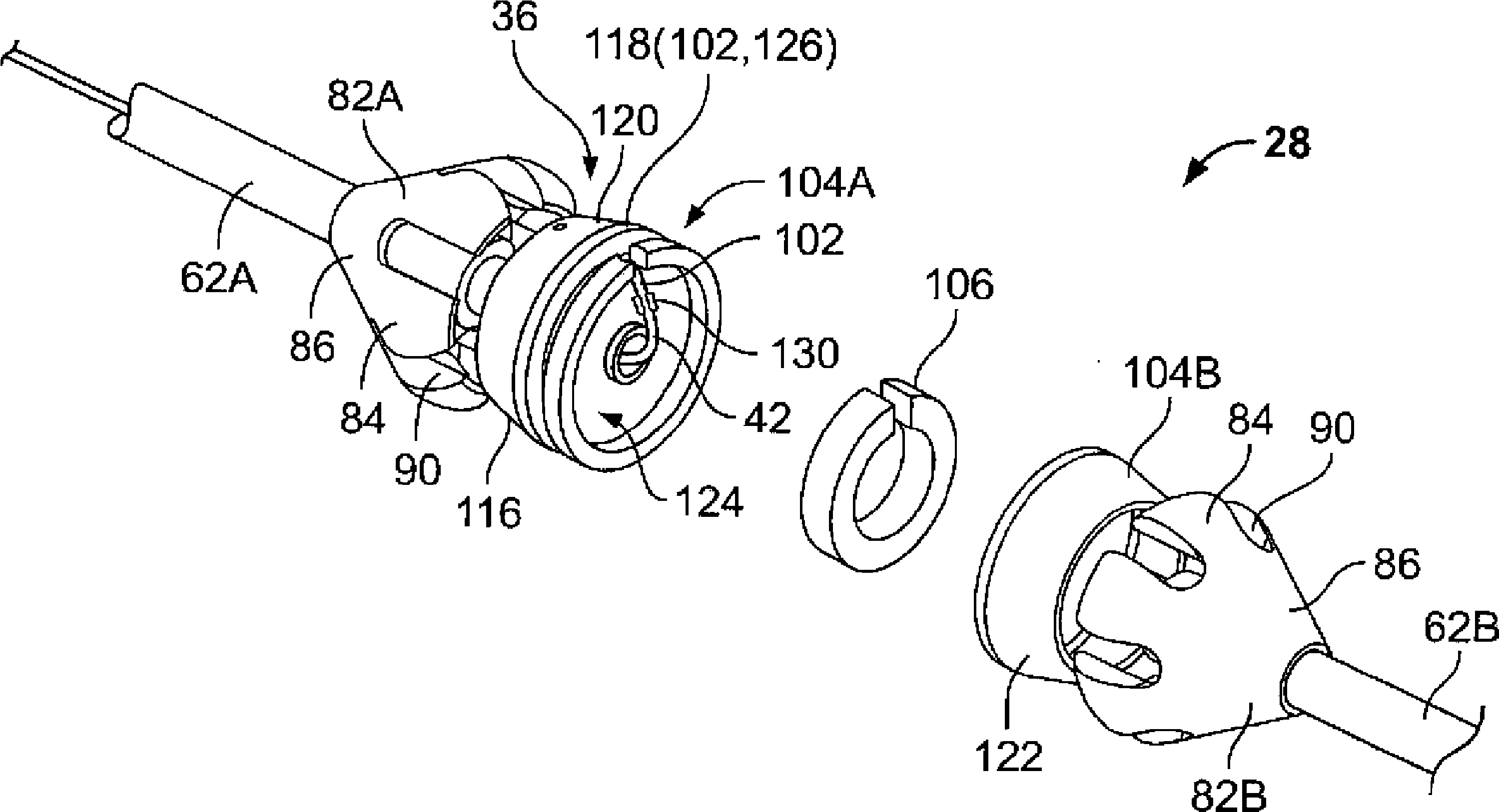

[0015] exist figure 1 An example of an inspection assembly 10 according to aspects of the invention is schematically shown in . It should be appreciated that the examples are for illustration purposes only and do not necessarily suggest specific limitations on the scope of the invention. Inspection assembly 10 is used for elongated tubular member 12 (for example, see in figure 2 Insertion inspection of the tubul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap