A controllable contact pressure polishing device

A polishing device and contact pressure technology, applied in the direction of grinding/polishing equipment, optical surface grinder, workpiece feed movement control, etc., to achieve the effects of alleviating medium and high frequency errors, good consistency, and improving surface shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

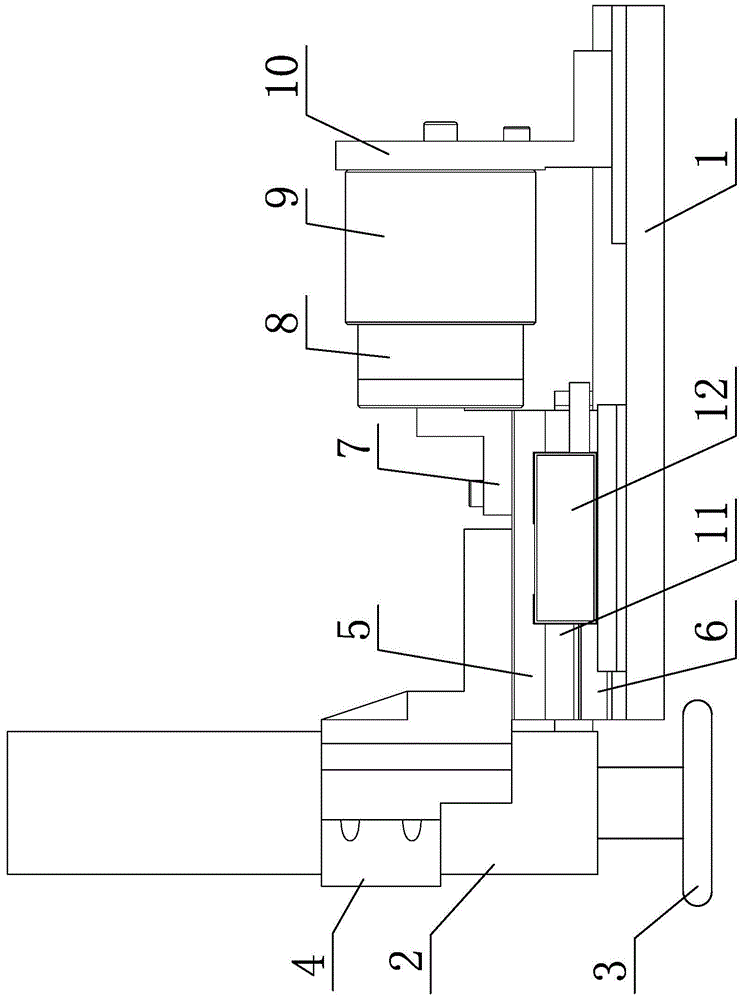

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, a controllable contact pressure polishing device described in this embodiment includes a polishing tool base 1, a polishing spindle 2, a polishing wheel 3, a polishing spindle connector 4, a linear slide slide 5, a linear slide base Seat 6, voice coil motor coil connector 7, voice coil motor and voice coil motor magnetic steel connector 10, polishing tool base 1 is horizontally arranged, polishing main shaft 2 is vertically arranged on one end of polishing tool base 1, and polishing main shaft 2 The axis is perpendicular to the upper surface of the polishing tool base 1, the polishing wheel 3 is installed on the lower end of the polishing spindle 2, the polishing spindle 2 is connected to the front of the linear slide slide 5 through the polishing spindle connector 4, and the linear slide slide 5 is installed on the polishing tool base 1 through the linear slide base 6, and the voice coil motor...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a controllable contact pressure polishing device described in this embodiment also includes a grating 11 and a reading head 12, the grating 11 is installed on the slide plate 5 of the linear slide table, and the reading head 12 is installed on the polishing tool base 1 At the front, the read head 12 is used to read the position signal on the grating 11 .

[0011] The technical effect of this embodiment is: set in this way, in the process of polishing pressure control, after the command of the controlled contact pressure value is issued, the precise position of the linear sliding table slide plate fixedly connected with the polishing spindle is obtained by the grating and the reading head, according to this The position information determines the value of the current input to the voice coil motor. Other components and connections are the same as those in the first embodiment.

[0012]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com