Bench saw

A table saw and follower blade technology, which is applied to circular saws, sawing equipment, wood processing equipment, etc., can solve the problems of high processing cost, inconvenient and fast assembly and disassembly of the follower blade, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

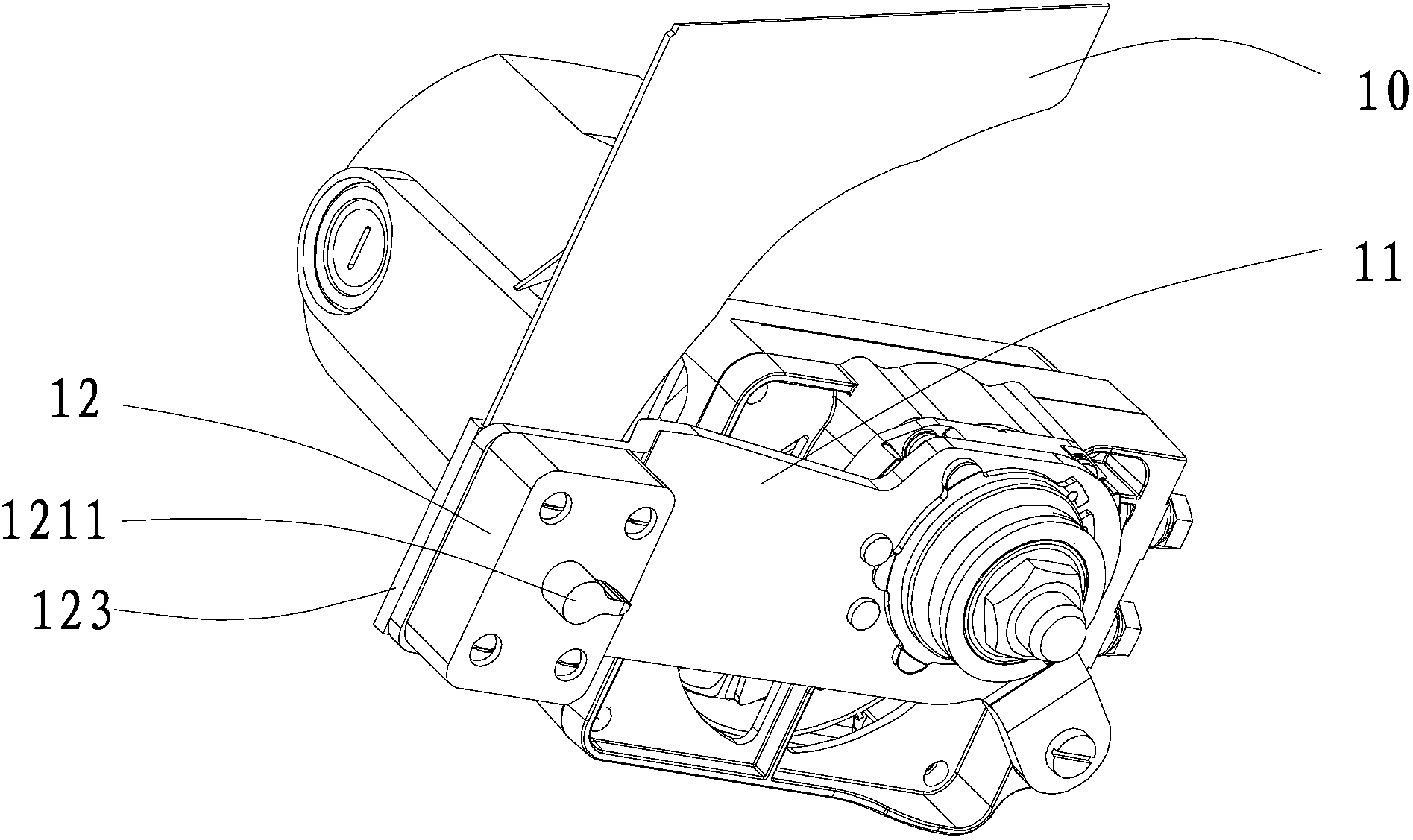

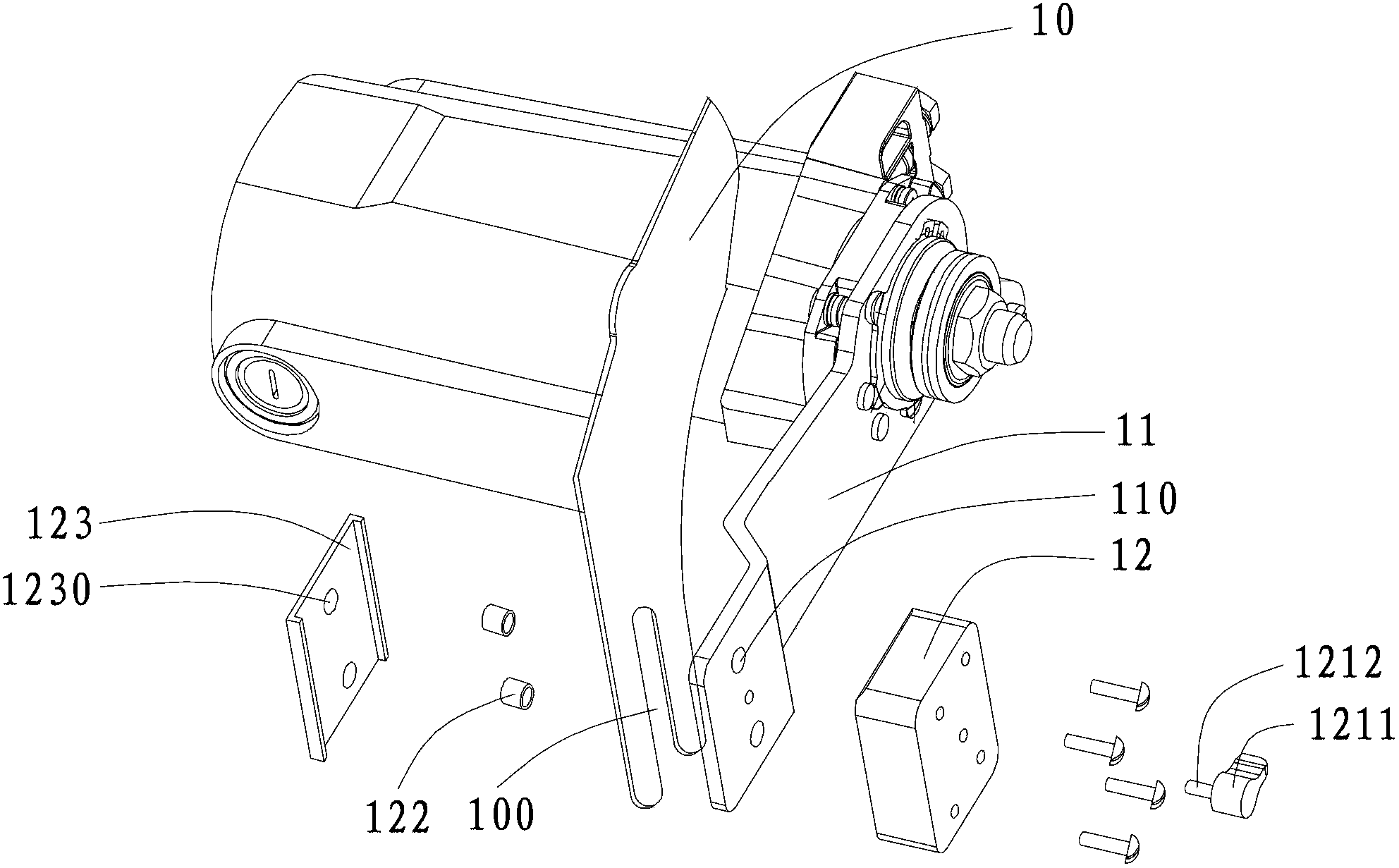

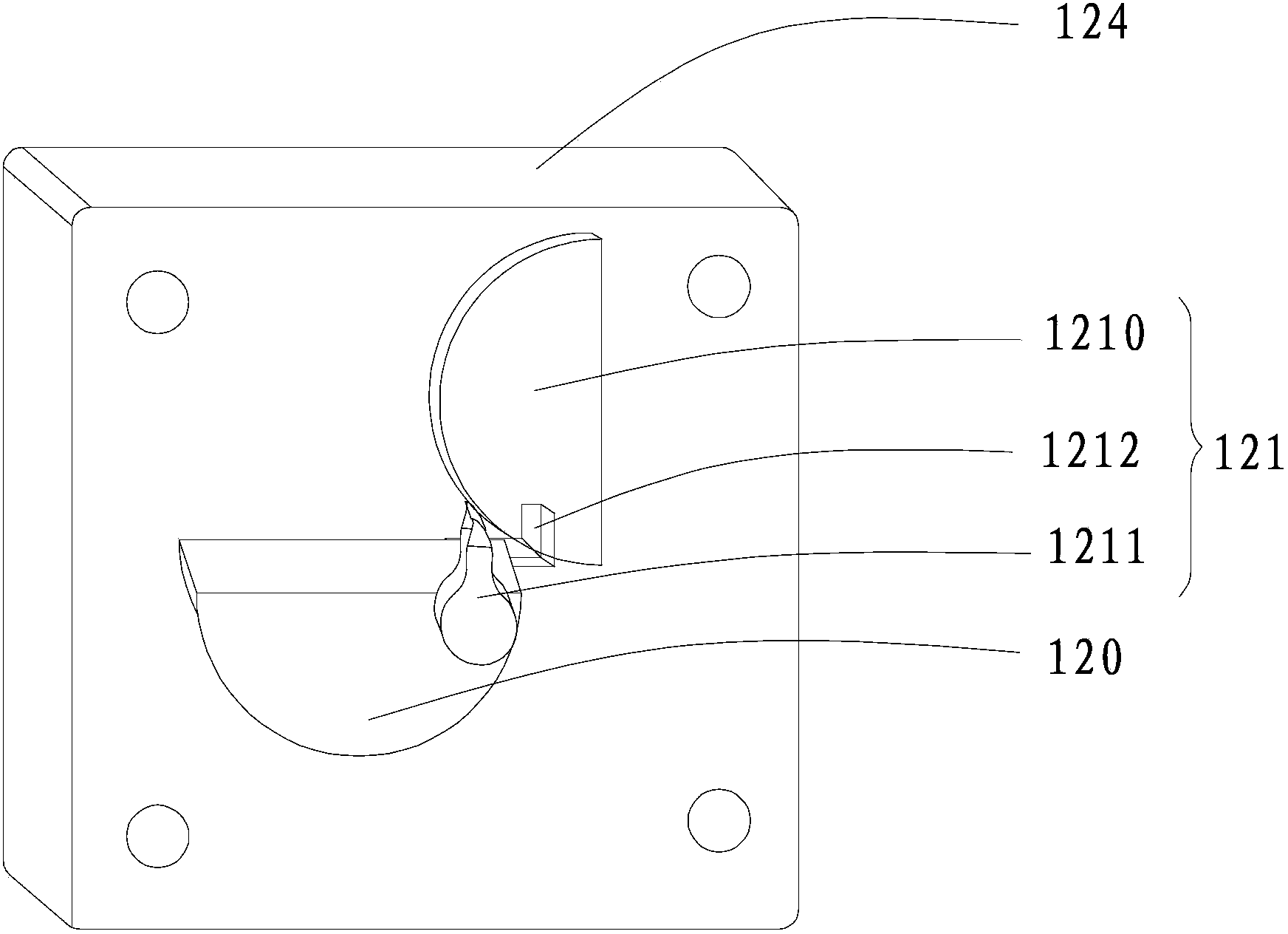

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , figure 2 As shown, a table saw includes a heel blade 10, a heel blade arm 11, and a locking mechanism 12. The heel blade 10 is detachably mounted on the heel blade arm 11, and the locking mechanism 12 It is fixed on the heel blade arm 11 ; the locking mechanism 12 includes a magnetic piece 120 , and the magnetic piece 120 fastens the heel blade 10 . The magnetic part 120 has a magnetic field and can generate a magnetic force. The magnetic force forms an adsorption force on the follower blade 10, adsorbs the follower blade 10 and fastens it to the follower blade arm 11, and the heel blade arm 11 does not affect The magnetic force between the magnetic part 120 and the heel blade arm 11 , and the magnetic force between the heel blade 10 and the magnetic part 120 are sufficient to fasten the heel blade 10 . When it is necessary to fasten the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com