Projection nut feeding device

A projection welding nut and feeding device technology, which is applied in the field of guide pin devices, can solve the problems that the guide pin 3 cannot be fitted correctly, and the nut cannot be fed normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

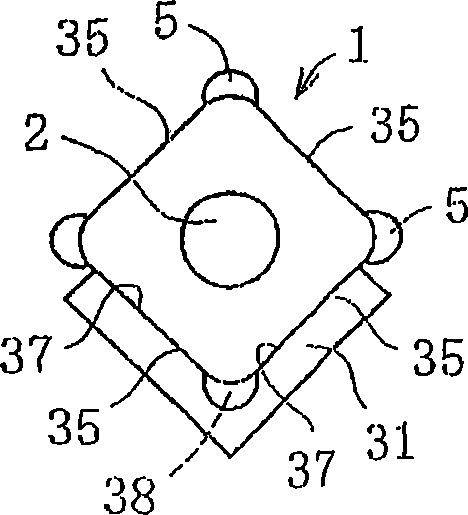

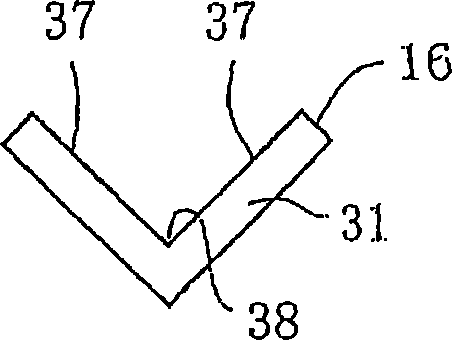

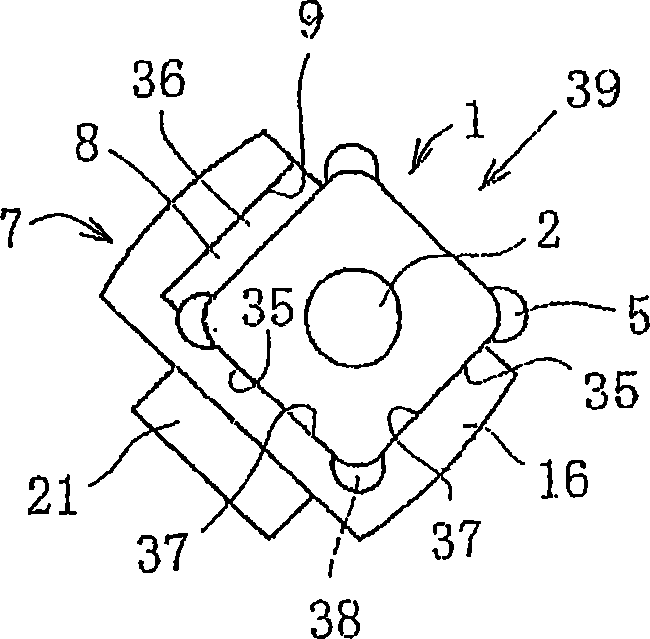

[0037] The feeding device of the projection welding nut of the present invention is a feeding device that improves the structure of attracting and holding the projection welding nut 1 at the front end of the feed rod 6, and other structures are the same as those described above. Figure 2 to Figure 5 The apparatus shown is the same. Therefore, the following, according to Figure 1A ~ Figure 1E The shape of the protruding piece 31 constituting a part of the surrounding wall 7 is described, and for other structures, in combination with Figure 2 to Figure 5 Instead, reference is made to matters already stated.

[0038] Figure 1A equivalent to figure 2 The view in the direction of the a arrow, Figure 1B show only Figure 1A Tab 31 in. The protruding piece 31 here is made by bending the steel plate to approximately 90 degrees, and an intersecting support surface 37 is formed on the inner side of the protruding piece 31 for supporting the adjacent outer surface 35 of the nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com