Headlamp for vehicle

A technology for headlights and vehicles, which is applied to vehicle lighting systems, headlights, vehicle parts, etc., can solve the problems of increasing the rotation radius of the lamp module, reducing the design matching, and being difficult to install the lamp module. The effect of assembling lamp modules, reducing interference and reducing assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

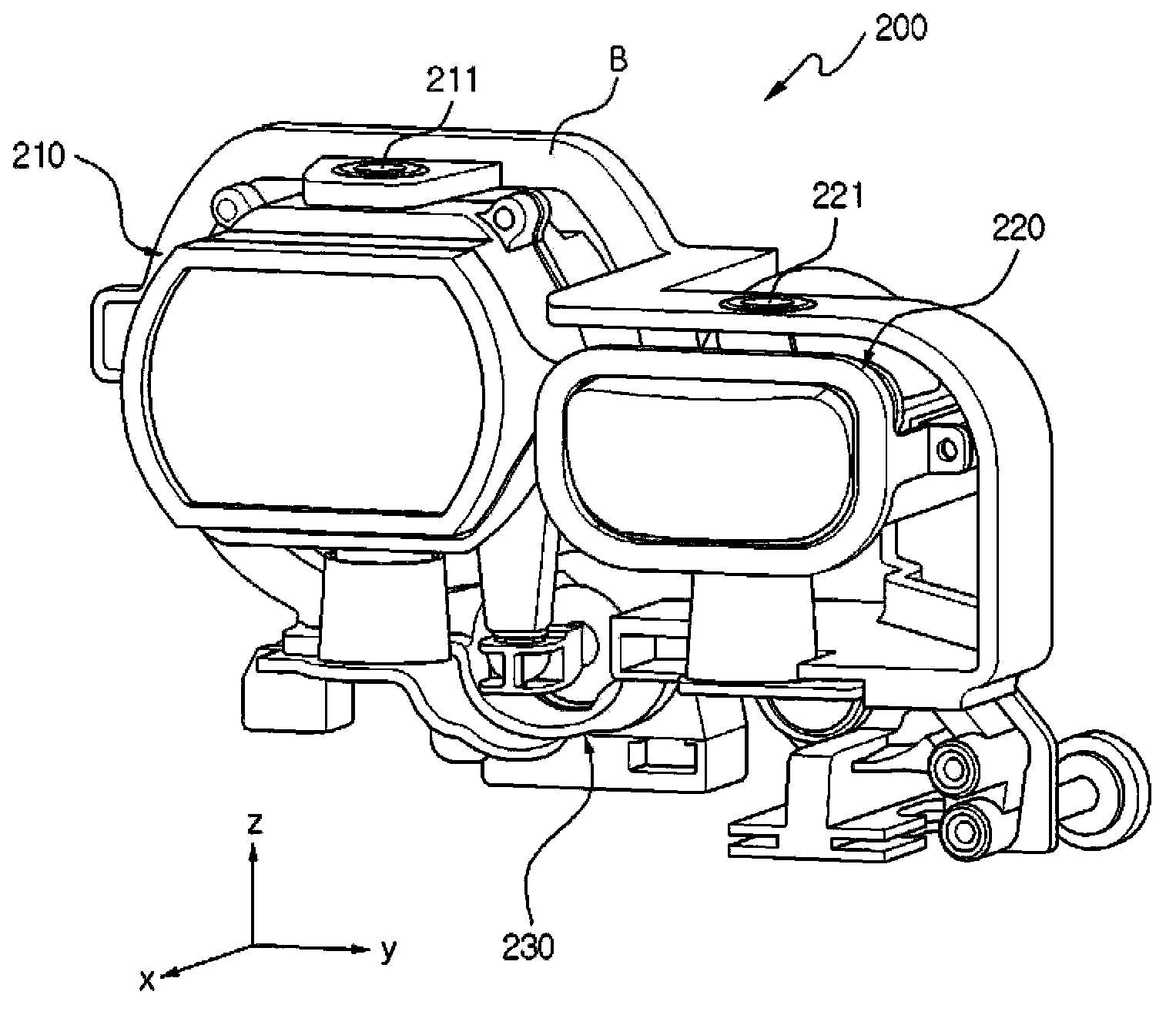

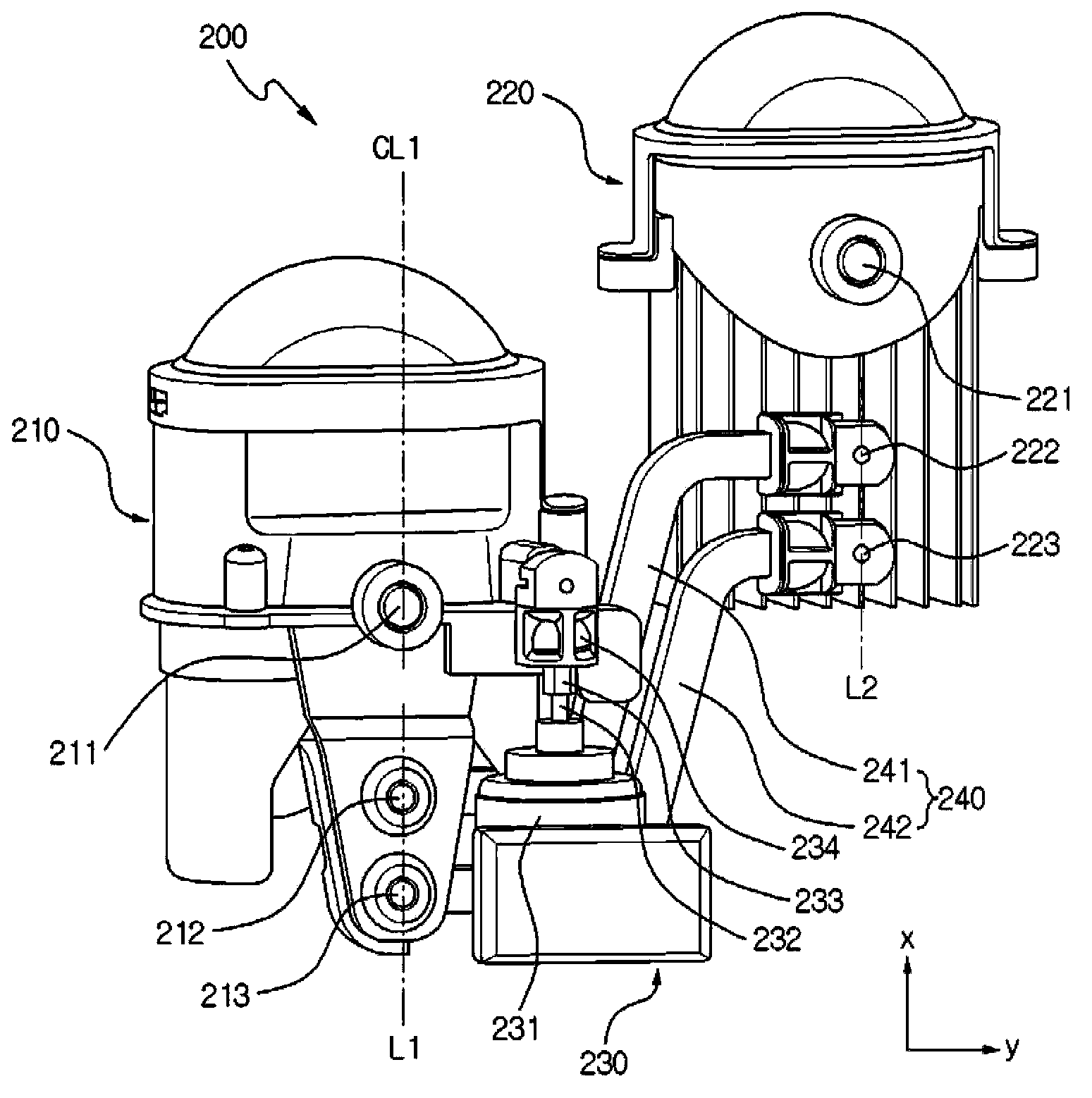

[0046] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to clearly express the technical solution of the present invention. However, in the description of the present invention, if the description of known techniques affects the clarity of the gist of the present invention, the description will be omitted. The thickness of lines or the size of components shown in the drawings are exaggerated for clarity and convenience in description, and the following terms are defined according to the functions in the present invention, and are not consistent with the intentions of designers and manufacturers or usage practices There are some differences, so these terms must be defined based on the overall content of this specification. The same diagram number (reference number) in the specification refers to the same factor.

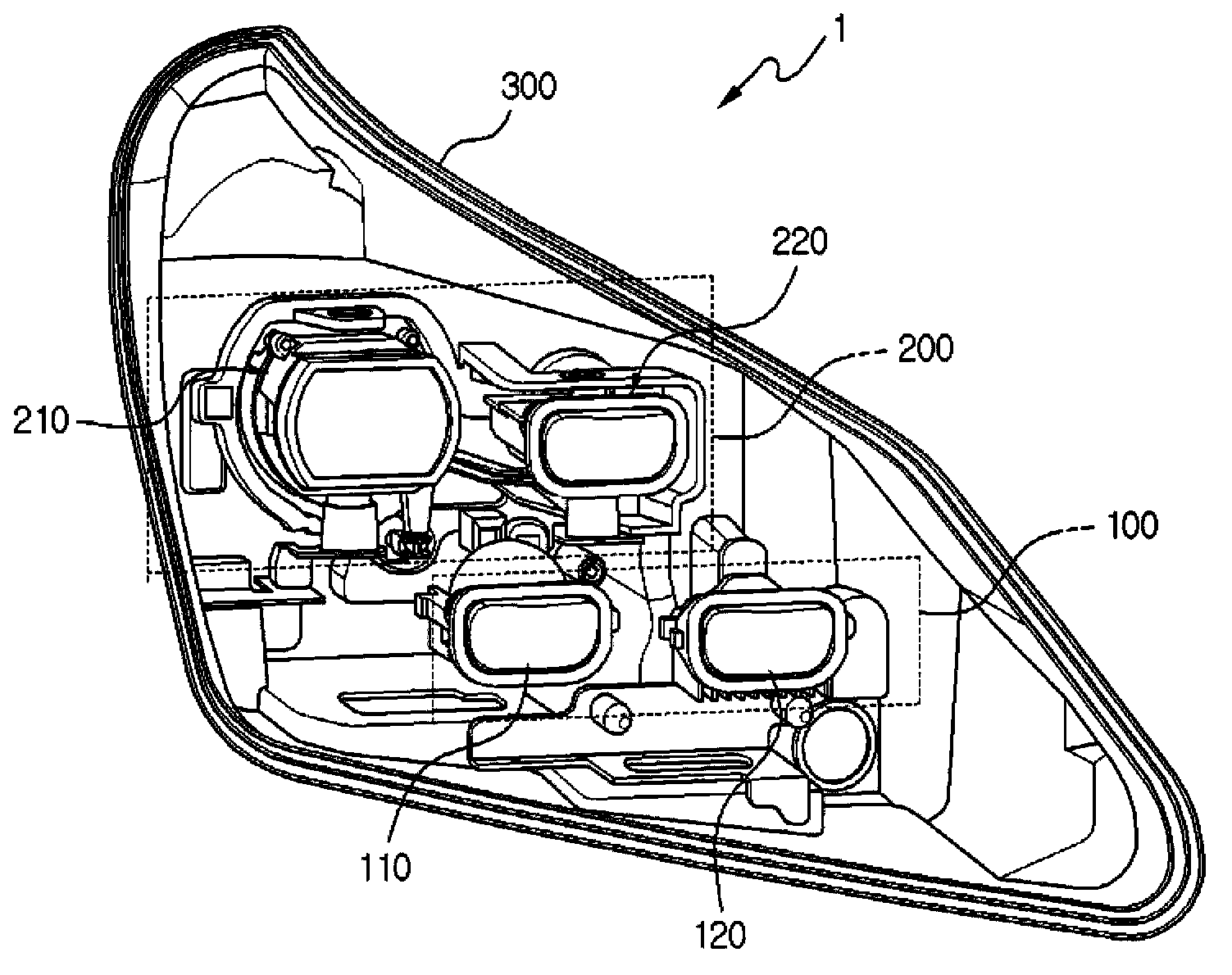

[0047] The vehicle headlamp 1 of the present invention will be described in deta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com