Support and Construction Method of Back-tensioning Load-bearing Construction of Bridge

A construction method, reverse pull technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., to avoid the impact of floods, fast construction period, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

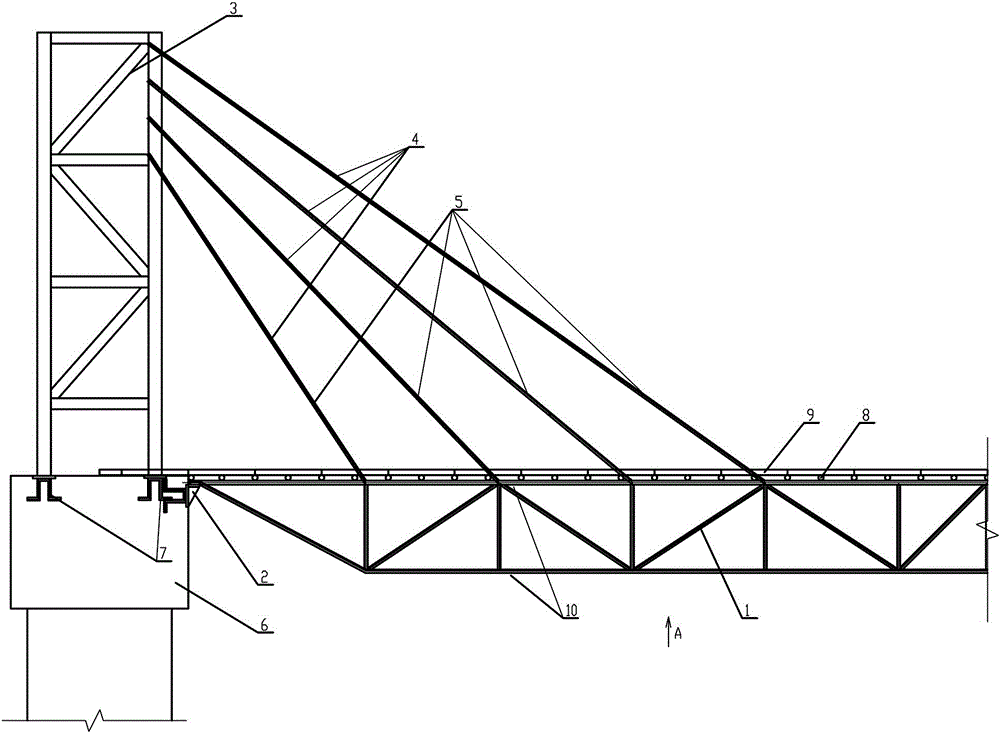

[0030] Such as figure 1 , 2 Among them, a bridge anti-back pull load-bearing construction support, including the abutment foundation 6, the tie rod column 3 is buried in the abutment foundation 6 through a plurality of steel plate bases 7, and the load-bearing ear plate 2 is buried on the side wall of the abutment foundation 6;

[0031] The steel bar load-bearing piece 1 and the diagonal brace 10 form a frame structure beam, one end of the frame structure beam is connected with the load-bearing ear plate 2 , and the upper end surface of the frame structure beam is connected with the tie rod column 3 through a plurality of tie rods 4 . With this structure, the concrete cast-in-place construction of the bridge girder body can be carried out on the entire construction support.

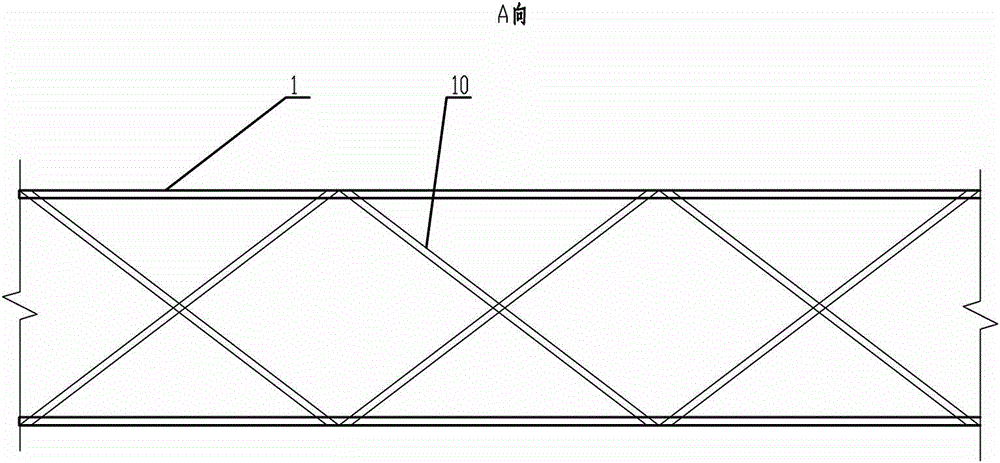

[0032] Preferably, the steel bar load-bearing sheet 1 is welded by a plurality of triangular strip steel bars. The diagonal brace 10 is an "X" shaped diagonal brace, which is used to overcome the left a...

Embodiment 2

[0037] On the basis of embodiment 1, a kind of construction method that adopts the bridge reverse pull load-bearing construction support described in claim 1~6 may further comprise the steps:

[0038] 1. During the construction of the abutment foundation 6, the steel plate base 7 is buried in the structural concrete of the abutment foundation 6, and the load-bearing ear plate 2 is welded and fixed with the steel plate base 7 during processing;

[0039] 2. Pre-process the steel bar load-bearing piece 1 in the steel bar processing plant, and use a small crane or other means, such as a hoist, electric or manual hoist, etc., to hoist and install it in place;

[0040] 3. Process the tie rod column 3 with channel steel or I-beam, and then weld and install it on the steel plate base; the processing can be pre-processed in the steel bar processing plant, or can be welded and processed on the abutment foundation 6 on-site.

[0041] 4. Weld or install the tie rod 4, and use the flange s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com