Bionic balance static-pressure valve

A bionic and balanced technology, applied in wellbore/well valve devices, production fluids, wellbore/well components, etc., can solve the problems of increasing motor power and restricting the life of water distributors, reducing volume and reducing The number of throws and the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

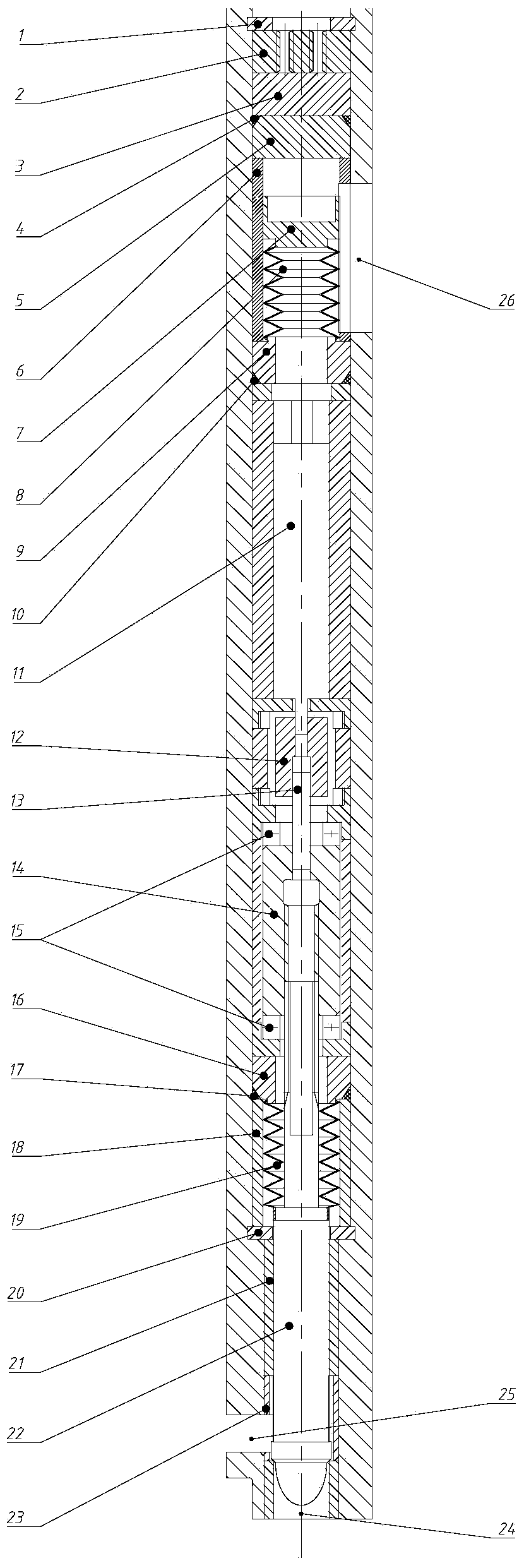

[0016] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

[0017] combine figure 1 , a water distributor valve with balanced static pressure involved in this example mainly includes: 1-upper circlip, 2-compression cover, 3-thick gasket, 4-wedge sealing ring, 5-valve compartment sealing cover, 6 -Upper bellows casing, 7-sliding sealing cover, 8-upper welding bellows, 9-upper bellows joint, 10-wedge seal ring, 11-motor, 12-coupling, 13-transmission shaft, 14- Lifting nut, 15-thrust bearing, 16-lower bellows joint, 17-wedge seal ring, 18-lower bellows sleeve, 19-lower welded bellows, 20-lower circlip, 21-valve sleeve, 22- Tapered spool, 23-middle sleeve.

[0018] The upper welded bellows 8 is welded with the sliding seal cover 7 and the upper bellows joint 9 to form the upper sealing structure; the lower welded bellows 19 is welded to the lower bellows joint 16 and the middle part of the tapered valve core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com