Optical coupling lens and optical communication module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

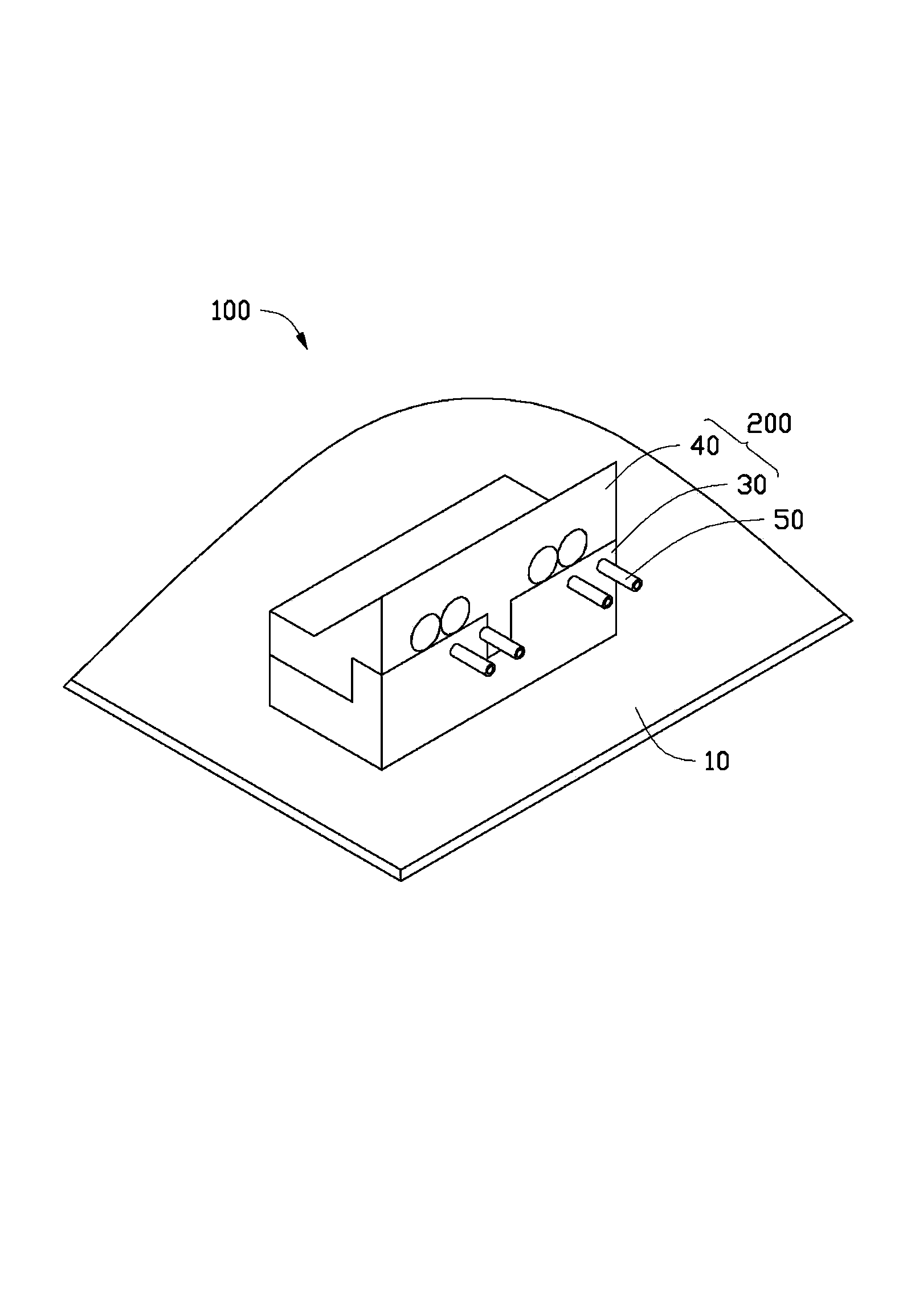

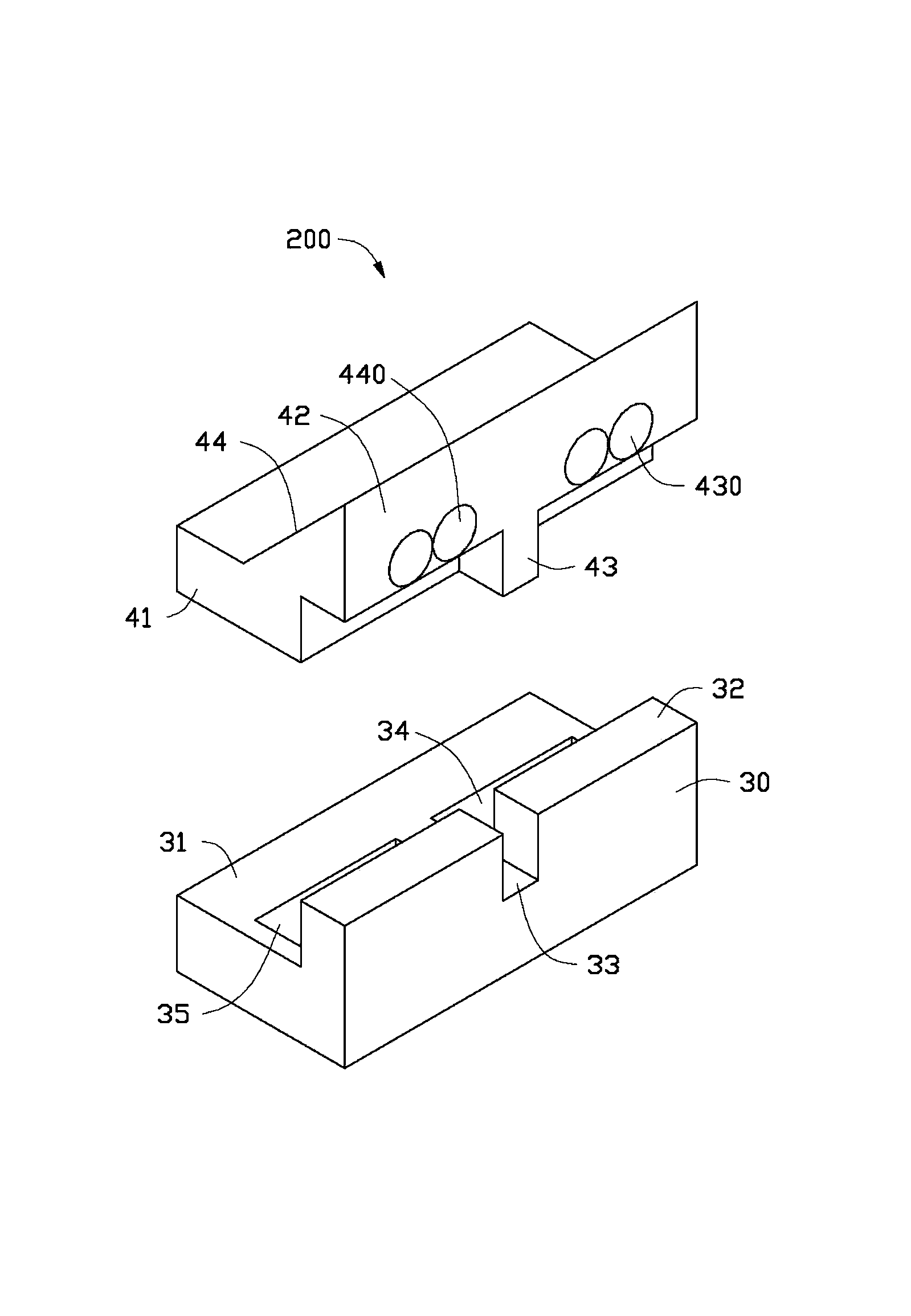

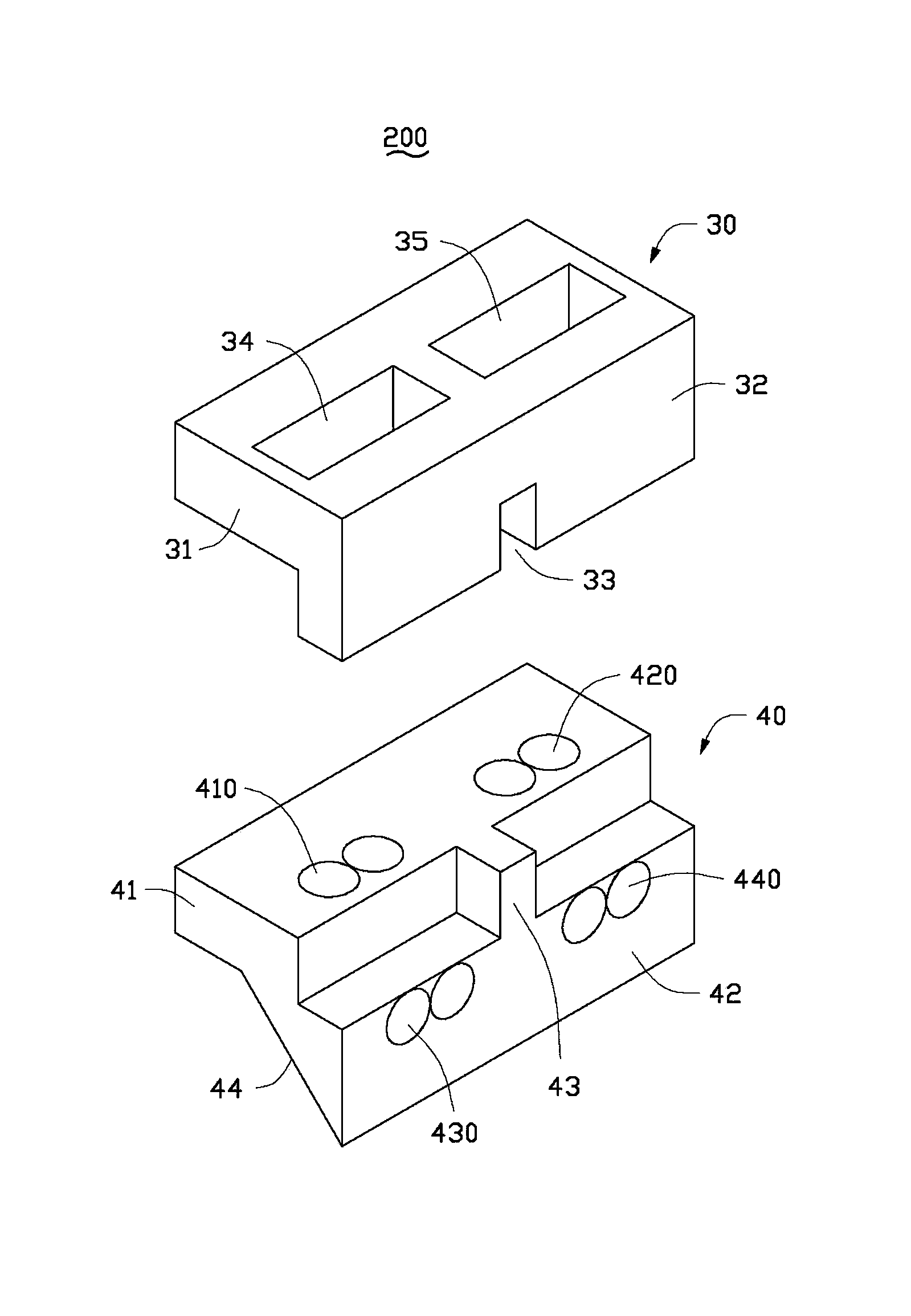

[0014] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the optical communication module 100 provided by the embodiment of the present invention includes a carrier board 10 , a light emitting element 21 , a photodetector 22 , a support unit 30 , a lens unit 40 and an optical fiber 50 .

[0015] Wherein, the light-emitting element 21 and the photodetector 22 are collectively referred to as a photoelectric component, and the combination of the support unit 30 and the lens unit 40 is called an optical coupling lens 200. The support unit 30 is fixed on the carrier plate 10, and the support unit 30 is used to support and fix the lens. The unit 40 aligns the lens unit 40 with the photoelectric unit and the optical fiber 50 to realize optical coupling.

[0016] The carrying board 10 is used to carry the light-emitting element 21 and the photodetector 22 , of course, it can also provide electric energy to make the light-emitting element 21 and the photodetector 22 work. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com