Pipe bending machine

The technology of a pipe bending machine and a pipe bending wheel, which is applied in the field of pipe bending machines, can solve the problems of shortening the service life of the pressure equalizing ring, thinning of the pipe wall, deformation of the hollow pipe, etc., and achieves the effect of high efficiency and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

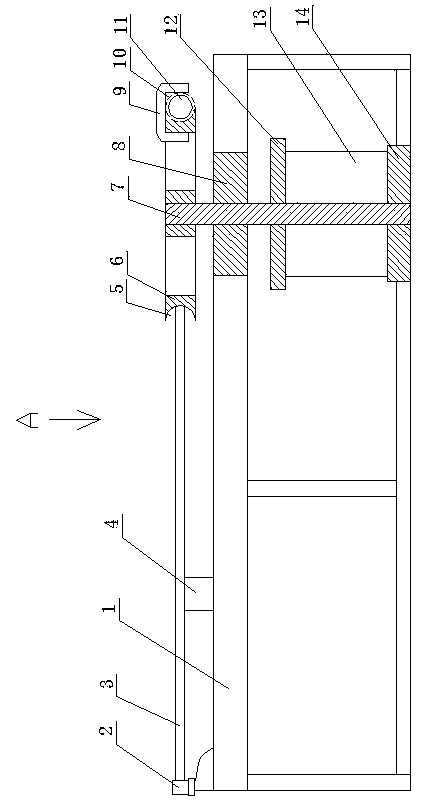

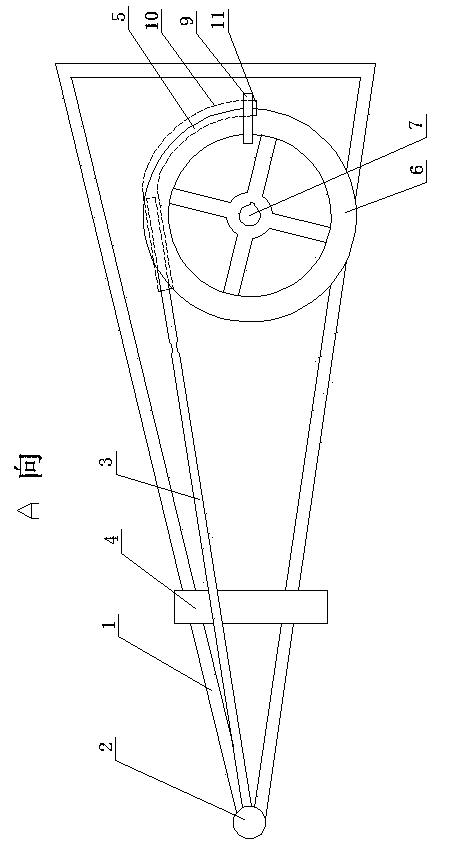

[0009] Such as figure 1 , 2 As shown, it is a pipe bending machine, including a frame 1, an anti-deflation plug 11 and a clamp 9, a lower support seat 14 is arranged below the frame 1, an upper support seat 8 is arranged above the lower support seat 14, and the upper support seat 8 is fixed Attached to rack 1. A pipe bending wheel 6 is arranged above one side of the frame 1, and the pipe bending wheel 6 is arranged horizontally. The outer circumference of the pipe bending wheel 6 is provided with an arc-shaped groove 5. The pipe bending wheel 6 is connected to the main shaft 7, and the main shaft 7 is arranged vertically. The main shaft 7 supports In the upper support seat 8 and the lower support seat 14. The main shaft 7 is connected with a reduction gear 12 , and the reduction gear 12 is connected with a power device 13 . The other side of the frame 1 is connected to a vertically arranged rotating shaft 2, and the connecting rod 3 is connected to the rotating shaft 2. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com