Soft pipeline installing device

A kind of pipeline installation, soft technology, applied in the direction of hoses, pipeline brackets, pipes, etc., can solve the problems of increased cost, loose water pipes, not conforming to the design concept of container houses, etc., to achieve the effect of convenient installation and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

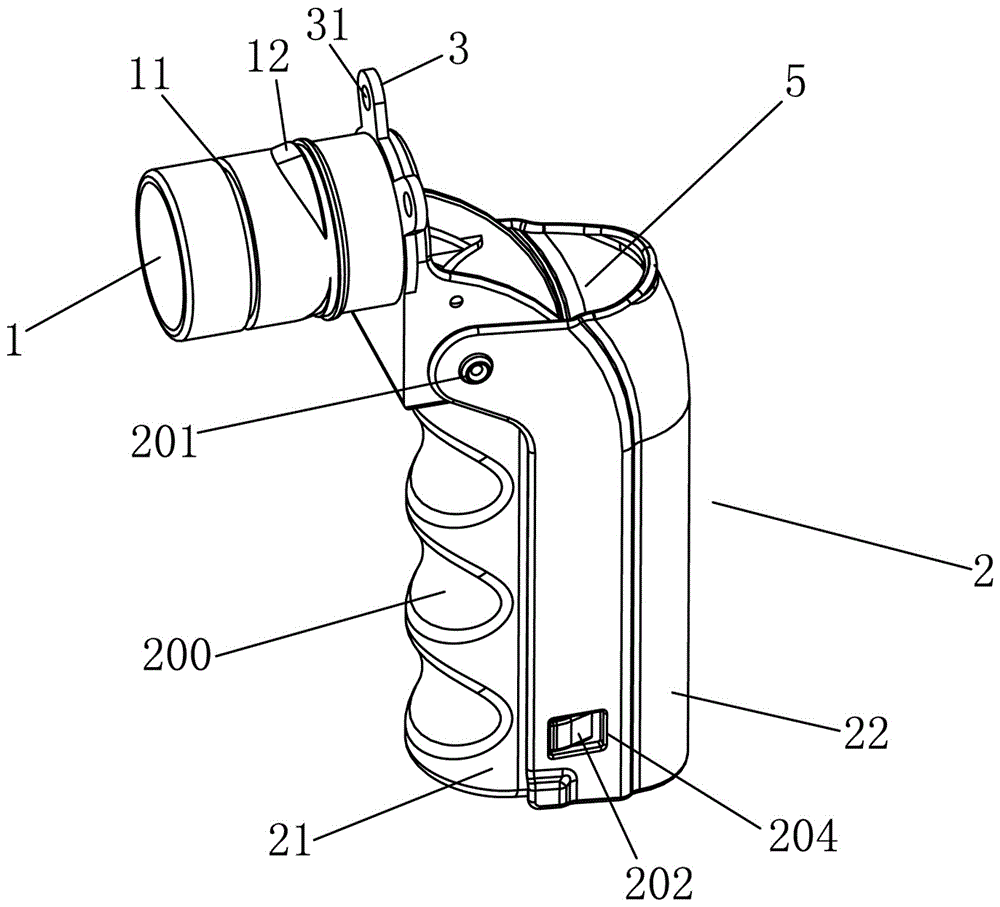

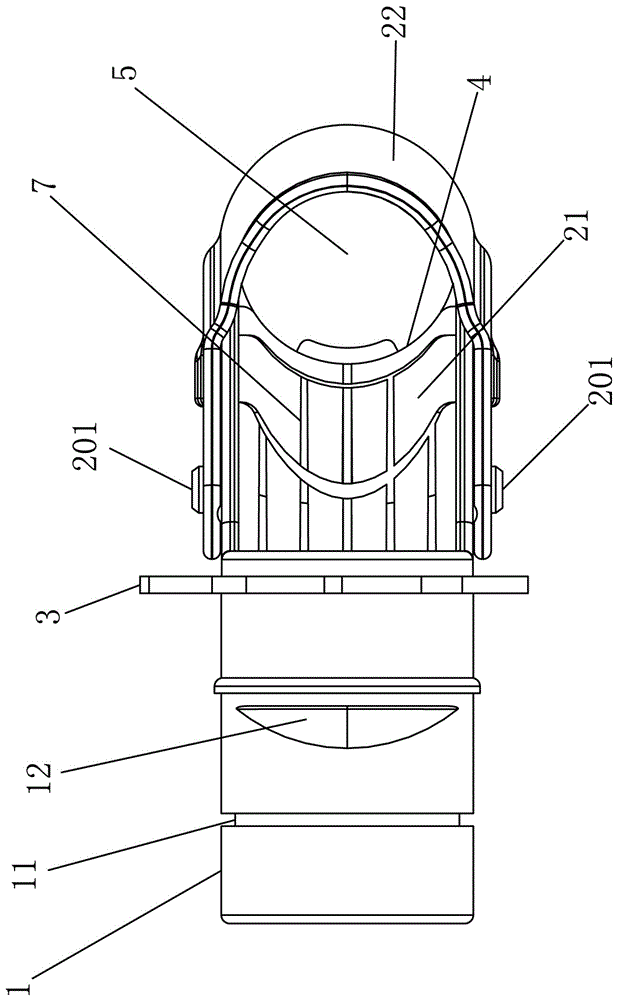

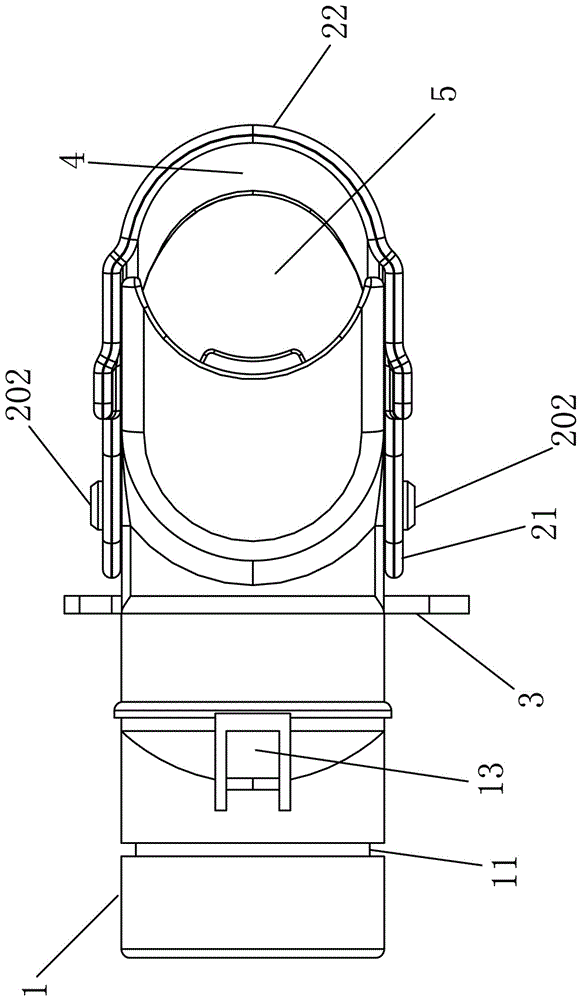

[0034] Example, combined with Figure 1 to Figure 13 As shown, a soft pipe installation device includes a gun barrel 1 and a handle 2, the gun barrel 1 is a hollow gun barrel, the inner diameter of the gun barrel 1 is greater than the diameter of the soft pipe 100, and the outer wall of the gun barrel 1 is provided with intervals The groove 11 for cutting the length of the gun barrel 1 is convenient, and the groove 11 is wound around the outer wall of the gun barrel 1 . The gun barrel 1 is also provided with an anti-off flange 12 and an anti-off clip 13, the surface of the anti-off flange 12 is inclined to form an anti-off flange 12 with a guide slope, and the anti-off flange 12 is integrated with the gun barrel 1 form. The surface of the anti-off strip 13 is inclined to form an anti-off strip 13 with a guide slope, the top of the anti-off strip 13 is hollowed out with the side wall of the gun barrel 1, and the bottom of the anti-off strip 13 is integrally formed with the gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com