a building support

A technology for building and frame feet, applied in the field of building supports, can solve problems such as construction safety affecting building quality, high requirements for ground flatness, and easy damage to support components, achieving the effects of good levelness, reduced material consumption, and balanced force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

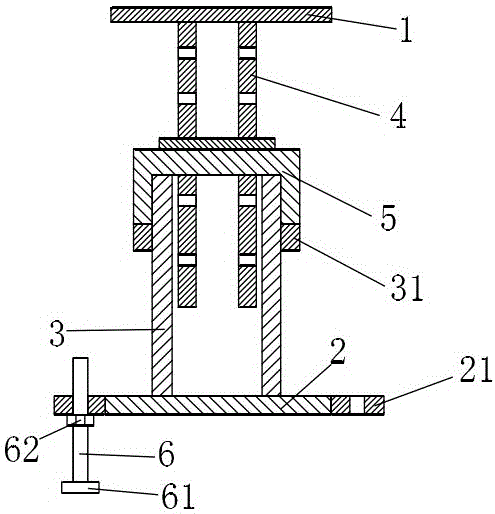

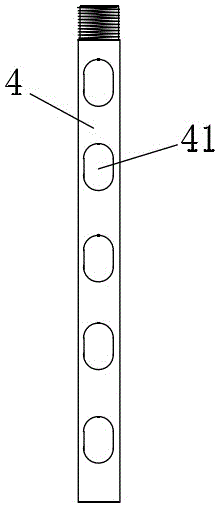

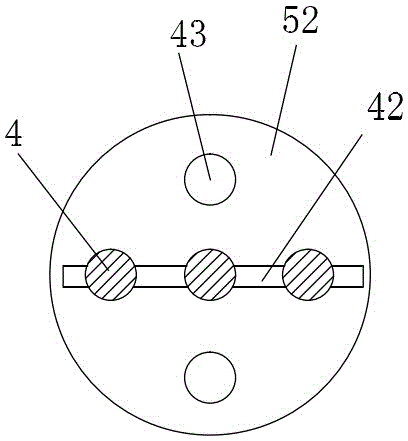

[0043] A kind of construction bracket, comprises upper supporting plate 1 and lower supporting plate 2, and described lower supporting plate 2 is vertically provided with guide tube 3, and described upper supporting plate 1 lower surface is vertically provided with several supporting rods 4, and described supporting The bottom end of the rod 4 is connected with a support sleeve 5 which is sleeved on the guide cylinder 3 and can slide up and down along the guide cylinder 3. The top of the support sleeve 5 is provided with a through hole 43 adapted to the support rod 4. The support The rod 4 is set through the through hole 43, and several through grooves 41 are horizontally arranged on the support rod 4 from top to bottom. 3 is also covered with an adjustment ring 31, the adjustment ring is screwed to the outer surface of the guide cylinder 3, the adjustment ring 31 is against the bottom end of the support sleeve 5, and the outer edge of the lower support plate 2 is evenly distri...

Embodiment 2

[0049] The difference from the above embodiment is that the support sleeve 5 includes a support plate 52, a support foot 53 and a collar 51 arranged in sequence from top to bottom, the collar 51 abuts on the adjustment ring 31, and the support The rod 4 is inserted into the support plate 52 , the lower end of the positioning insertion strip 42 abuts on the support plate 52 , and the positioning insertion strip 42 passes through one or more support feet 53 . The through holes 43 on the support plate 52 are 6 uniformly distributed around the center of the support plate 52 . The thickness of the support plate is 15cm.

Embodiment 3

[0051] The difference from the above-mentioned embodiment is that there are three through holes 43 evenly distributed on the support plate 52, and there are three support rods. The same, and at least two of the through grooves at the corresponding height positions are located on the same axis. There are a plurality of positioning inserts, and the positioning inserts can be inserted on the three support rods on the same plane, or the positioning inserts can be added on this basis, that is, the additional positioning inserts are inserted on the two support rods. the last slot of a support rod, or insert a positioning insert into the upper slot of the two support rods to ensure that each support rod is pierced with at least two positioning inserts. strip. The support in this arrangement has high strength, can be used to support a supported building with a heavy weight, and the components are not easy to be damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com