A mechanism for controlling crosslinkers

A cross-linking agent, No. 1 technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as difficulty in ensuring accurate control, clogged pipeline displacement, instability, etc., to achieve convenient and precise control, The effect of stable displacement and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

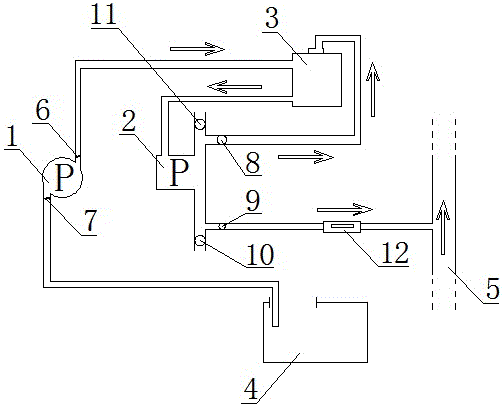

[0016] a kind of like figure 1 The mechanism for controlling the cross-linking agent shown in the figure, the arrow in the figure indicates the flow direction of the cross-linking agent, including the No. 1 liquid addition pump 1, the transition tank 3, and the No. Filter 1 at the liquid outlet of pump 1 and filter 2 7 at the liquid inlet of No. 1 liquid and pump 1 can filter the cross-linking agent multiple times to prevent impurities from entering the cross-linking agent to the greatest extent and ensure cross-linking. The cleaning of the coupling agent, and the filter screen can be easily disassembled and replaced and cleaned without affecting the normal use of the system.

[0017] The above-mentioned mechanism for controlling the cross-linking agent is also provided with the three-item port A of the first outlet of the No. 2 liquid addition pump 2 and the three-item port B of the second outlet of the No. 2 liquid addition pump 2; two of the above-mentioned three items of p...

Embodiment 2

[0022] After the cross-linking agent is mixed with the additive through the cross-linking agent pool 5 on the ground, it is pumped into the transition tank 3 on the sand mixing platform by the No. 1 liquid addition pump 1, and then the No. 2 liquid addition pump 2 is pumped from the transition tank 3 In the sand mixer manifold 5, liquid cross-linking is realized. When a small cross-linking agent displacement is required, the No. 2 liquid addition pump 2 is in a stable low-speed working state, and the required cross-linking displacement can be adjusted through valve A8 and valve B9, and can realize from zero to the maximum working capacity of the pump. The working range of cross-linking agent pump displacement is widened and precise control is realized.

[0023] According to the required cross-linking agent displacement, firstly, the No. 1 liquid addition pump 1 fills the cross-linking agent transition tank 3, and then turns on the No. 2 liquid addition pump 2, so that the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com